Quick-detachable large storage tank circular seam automatic welding inner support device

A quick-release, automatic welding technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to meet the needs of production tasks, dismantling structural nodes, and high labor intensity. The process is stable and reliable, the welding efficiency is improved, and the disassembly is simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

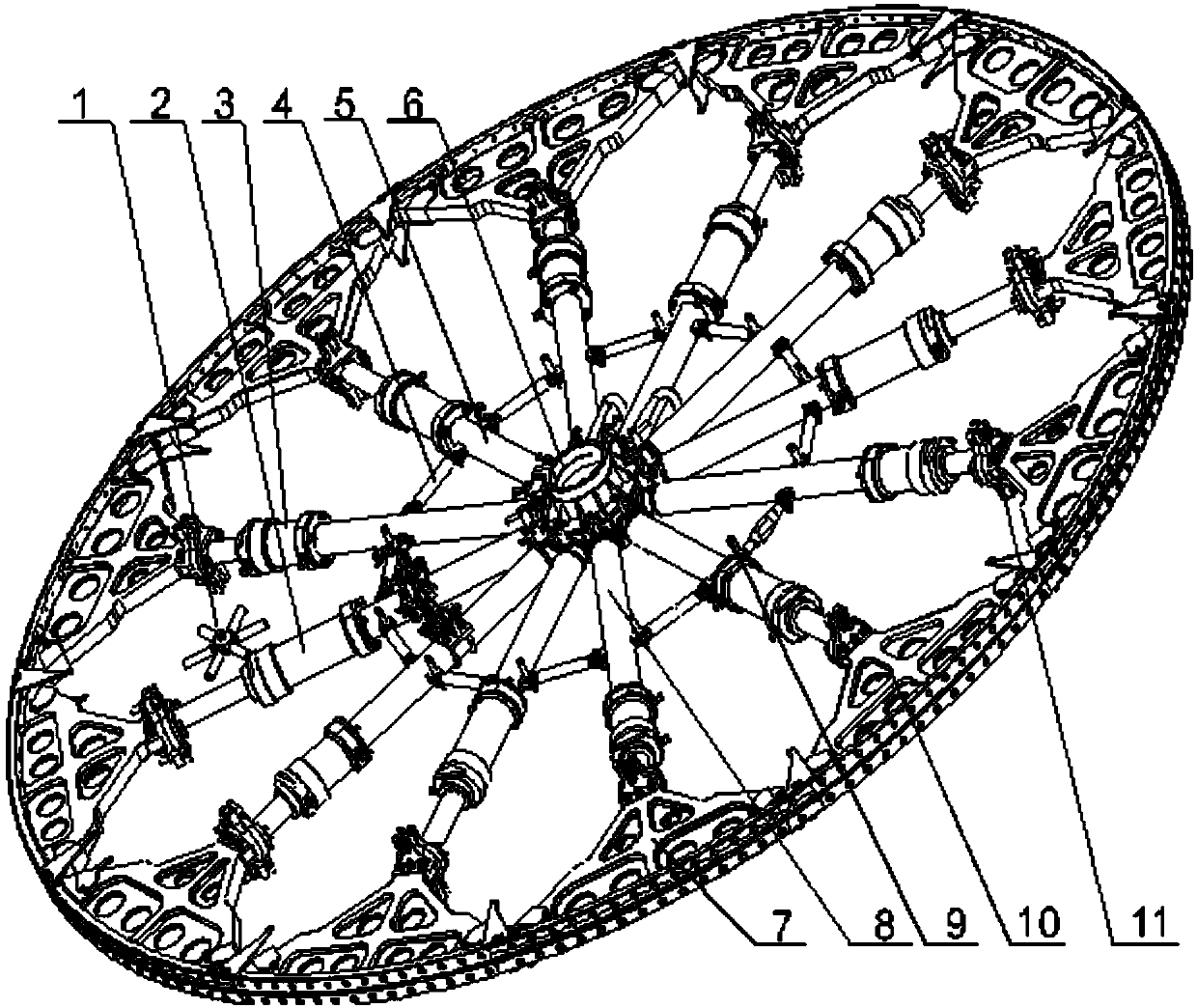

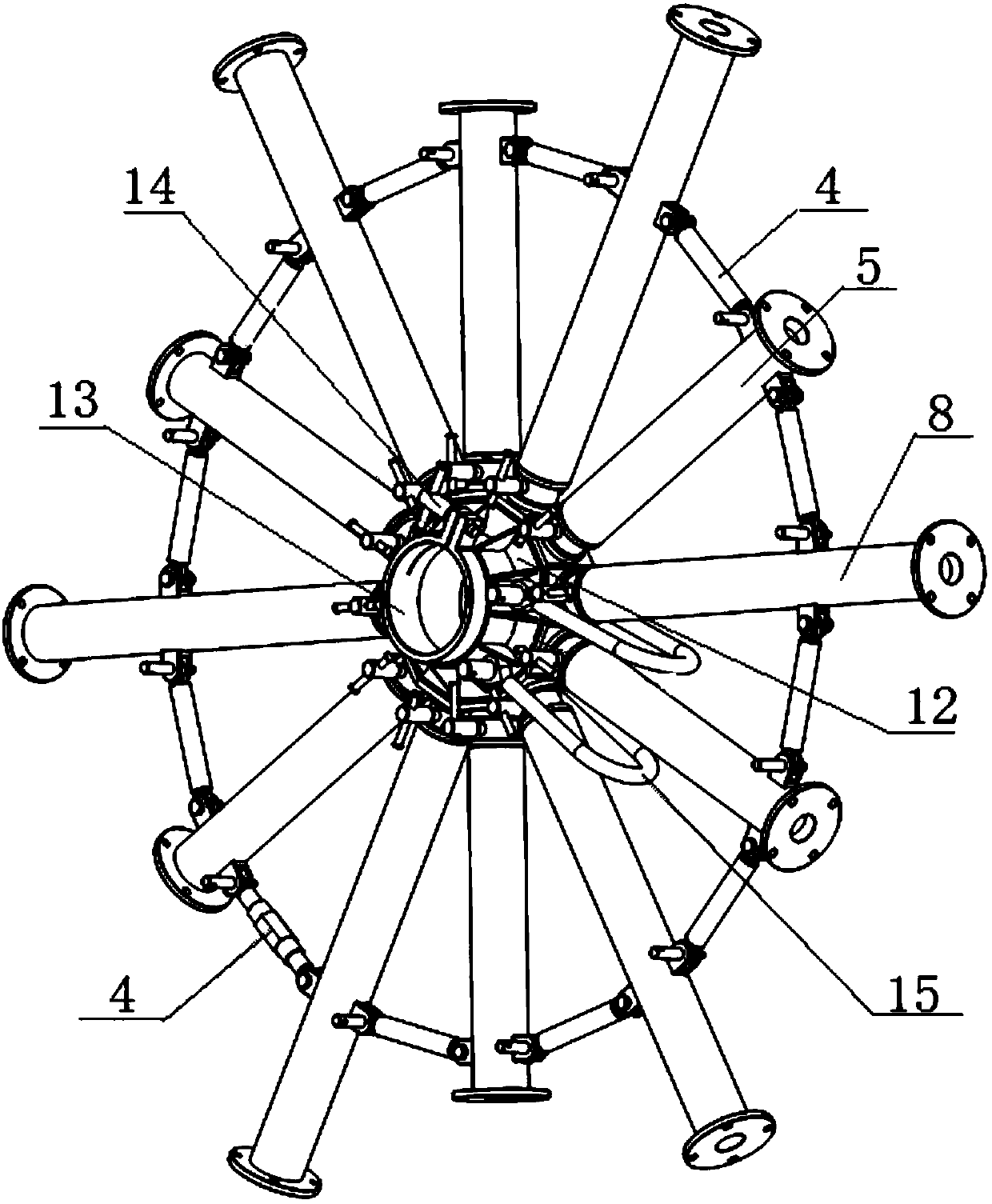

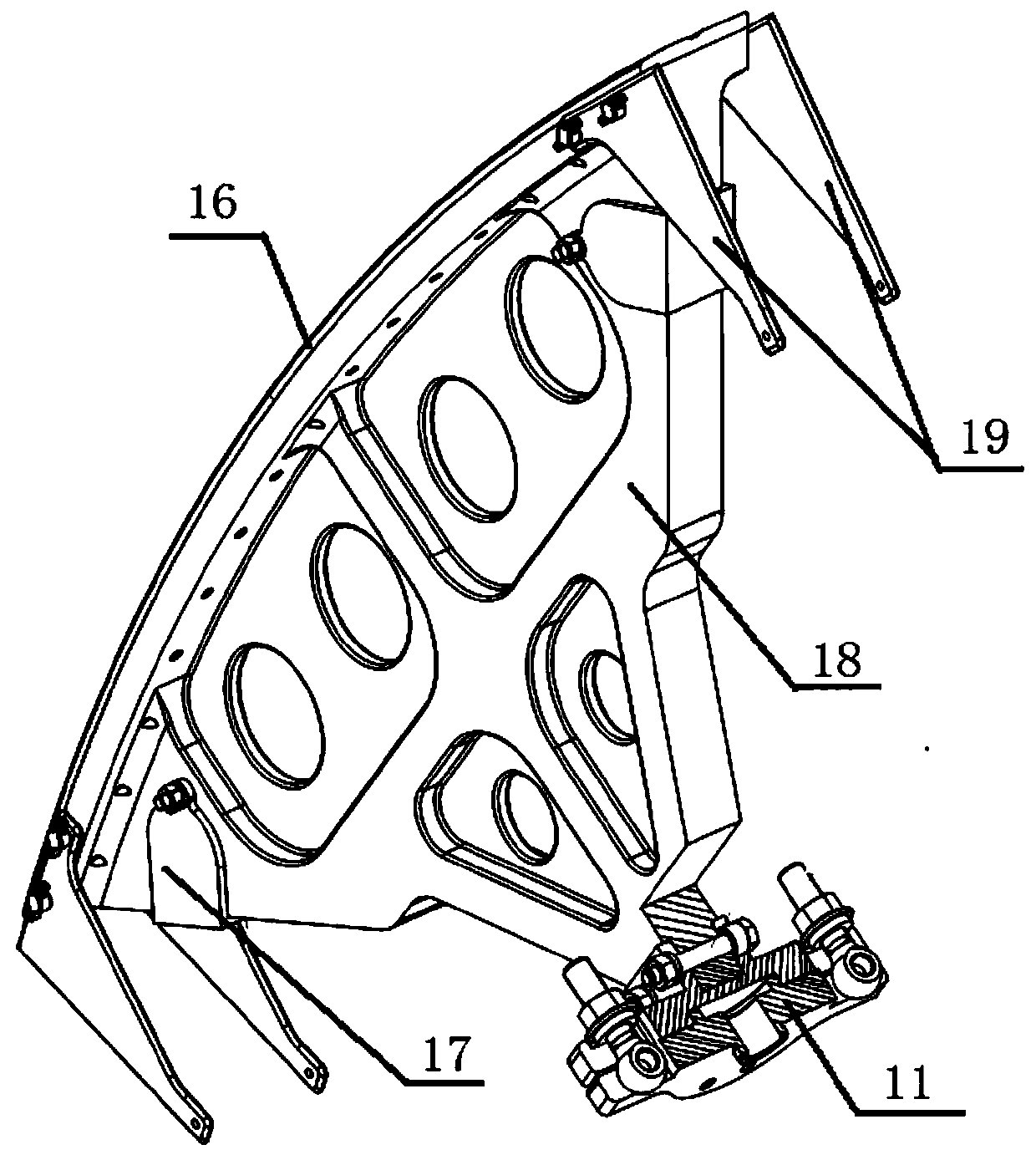

[0020] Embodiment 1: see Figure 1 to Figure 5 , a quick-detachable large-scale storage tank circular seam automatic welding internal support device, including an adjustable clamping shaft seat 6 arranged horizontally, so the outer wall of the adjustable clamping shaft seat 6 is uniformly staggered with long support rods 8 along its radial direction And the short support rod 5, the long support rod 8 and the short support rod 5 are located on the same horizontal plane, one end is detachably connected with the adjustable clamping seat, and the other end of the long support rod 8 is connected to an outer arc support through a short stroke cylinder 3 Block 7, the short stroke cylinder 3 is coaxially arranged with the long support rod 8, the other end of the short support rod 5 is connected to an inner arc support block 10 through a long stroke cylinder 2, the long stroke cylinder 2 and the short support rod 5 Coaxial arrangement, the long-stroke cylinder 2 and the short-stroke cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com