Non-back-ridgebuilt-up type all-steel big shuttering

An assembled and large formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems that the construction unit cannot configure itself, it is difficult to achieve design requirements, and the performance of decorative strips and other problems, to achieve excellent water clearing effect and flow use times, to meet the requirements of open seam decoration, and to achieve reliable strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

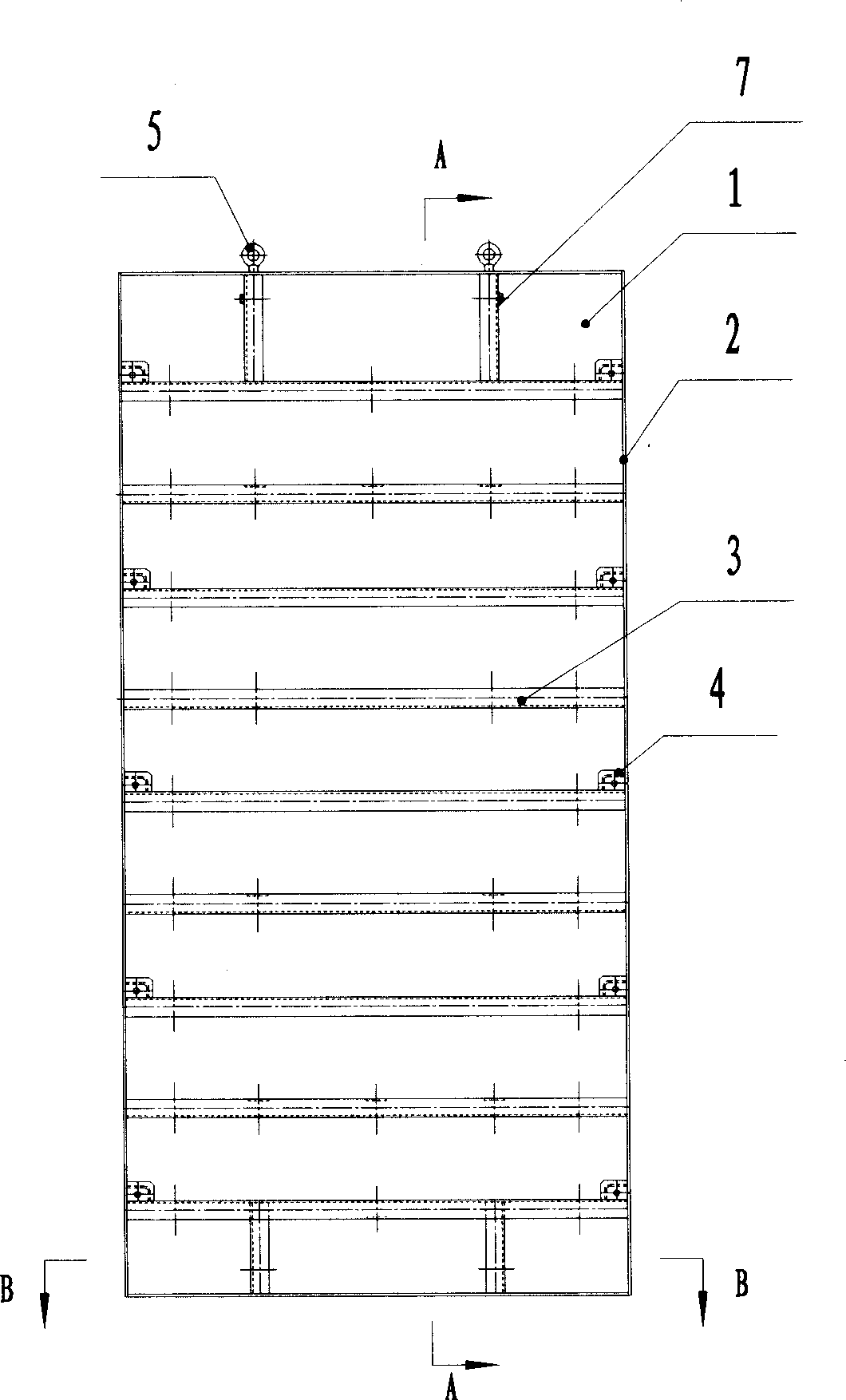

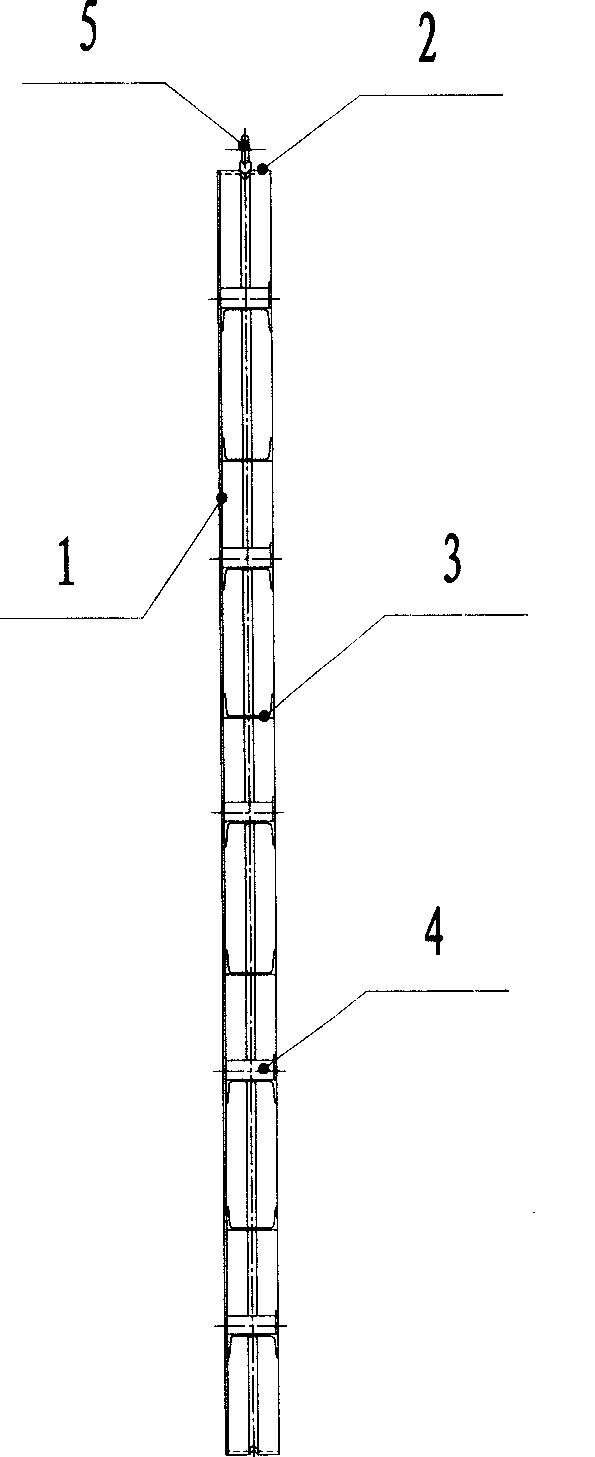

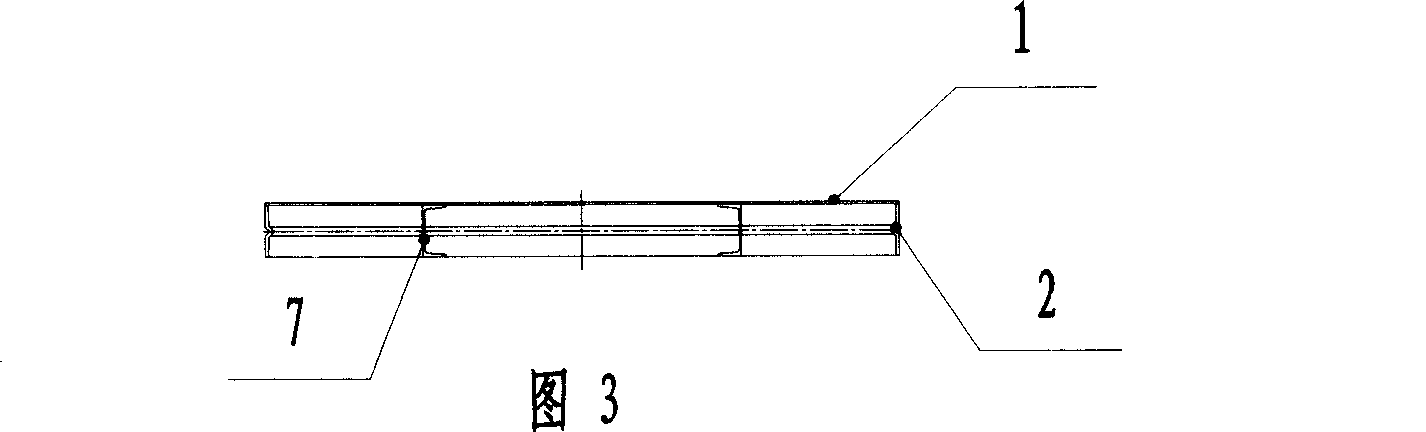

[0025] Accompanying drawing is the embodiment of the all-steel large formwork of the present invention without back corrugated assembly type, as figure 1 As shown, it includes a panel 1, a frame 2 and a support rib 3, the frame 2 is a curved frame with a convex edge, and its cross section is "{"-shaped, and four frames 2 form a rectangular frame; the support rib 3 is multiple, etc. The spacing is set between the two long frames 2 of the rectangular frame, and the two ends of each supporting rib 3 are fixedly connected to the two long frames 2 respectively. Reasonable intermittent welding fixation not only enhances the rigidity of the frame and ribs, but also enhances the plane rigidity of the formwork. The standard rectangular frame of this embodiment is 1500mm×3000mm, and the adjustment range is between 200 and 1500mm. The panel 1 is a 6mm hot-rolled steel plate, and the frame 2 is a special hot-rolled section steel with a "{"-shaped cross section, and the width is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com