Fresnel lens

A technology of Fresnel lens and lens sheet, applied in lens, optics, instrument, etc., can solve problems such as poor self-support, difficulty in fixing, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

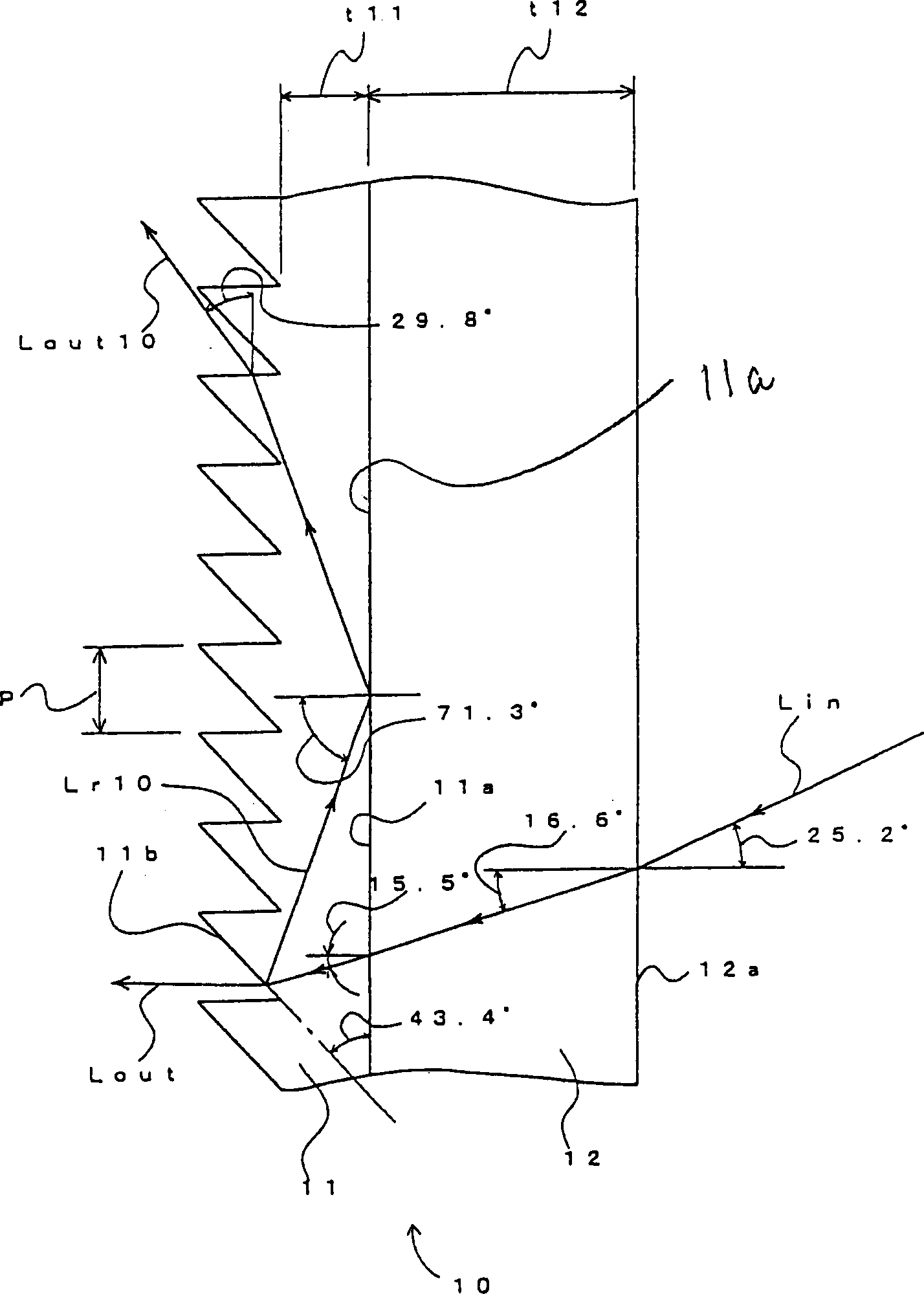

[0043] figure 1 It is a diagram explaining an example of the first embodiment of the Fresnel lens sheet according to the present invention.

[0044] In this embodiment, the Fresnel lens sheet 10 is provided with a lens layer 11 and a base material layer 12 , the diagonal size is 70 inches (aspect ratio is 4:3), and the focal length is 720 mm.

[0045] The lens layer 11 is a Fresnel lens shape with a pitch (pitch) P=0.1mm formed on the outgoing light side, a high refractive index layer with a refractive index n11=1.59, and a thickness t11=0.1mm from the bottom of the Fresnel lens . The lens layer 11 has a total reflection layer 11 a at the interface with the base material layer 12 .

[0046] The base material layer 12 is a parallel flat plate with a thickness t12 = 3 mm, and is a low refractive index layer made of acrylic resin with a refractive index n12 = 1.49. Also, in figure 1 In the figure, the plate thicknesses of the lens layer 11 and the base material layer 12, et...

no. 2 approach

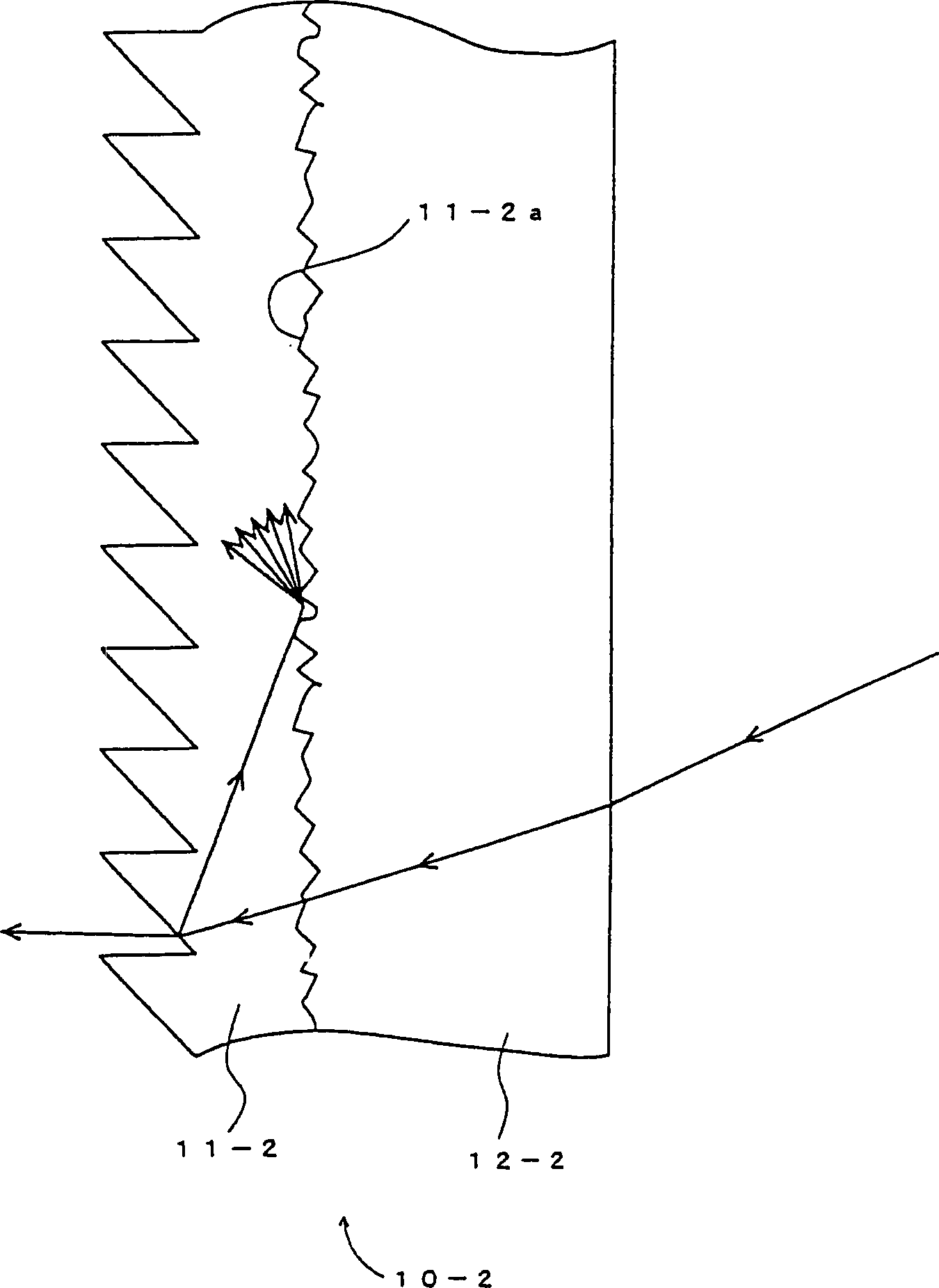

[0069] Figure 6 It is a figure explaining an example of 2nd Embodiment of a Fresnel lens sheet in this invention.

[0070] In this embodiment, the Fresnel lens sheet 40 is a Fresnel lens sheet having a lens layer 41 and a base material layer 42, a diagonal size of 50 inches (aspect ratio of 4:3), and a focal length of 700 mm.

[0071] In this Fresnel lens sheet 40, on the optical axis of the Fresnel lens sheet 40, at a position of a projection distance of 700 mm, the image is vertically projected by a projector using a liquid crystal or a DLP (Digital Light Processor) or the like. Image light, together with scattering means (not shown), forms a transmission type projection screen.

[0072] The Fresnel lens sheet 40 has a total reflection surface 40 a formed at the interface between the lens layer 41 and the base material layer 42 .

[0073] The lens layer 41 is to form a Fresnel lens shape with a pitch (pitch) P=0.1mm on the outgoing light side, a high refractive index laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com