Backlight module and optical film immobilizing method

A technology of backlight module and optical film, which is applied in optics, nonlinear optics, components of lighting devices, etc., and can solve the problems of cumbersome assembly process, high assembly man-hours and assembly costs of backlight module 100, and many assembly components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

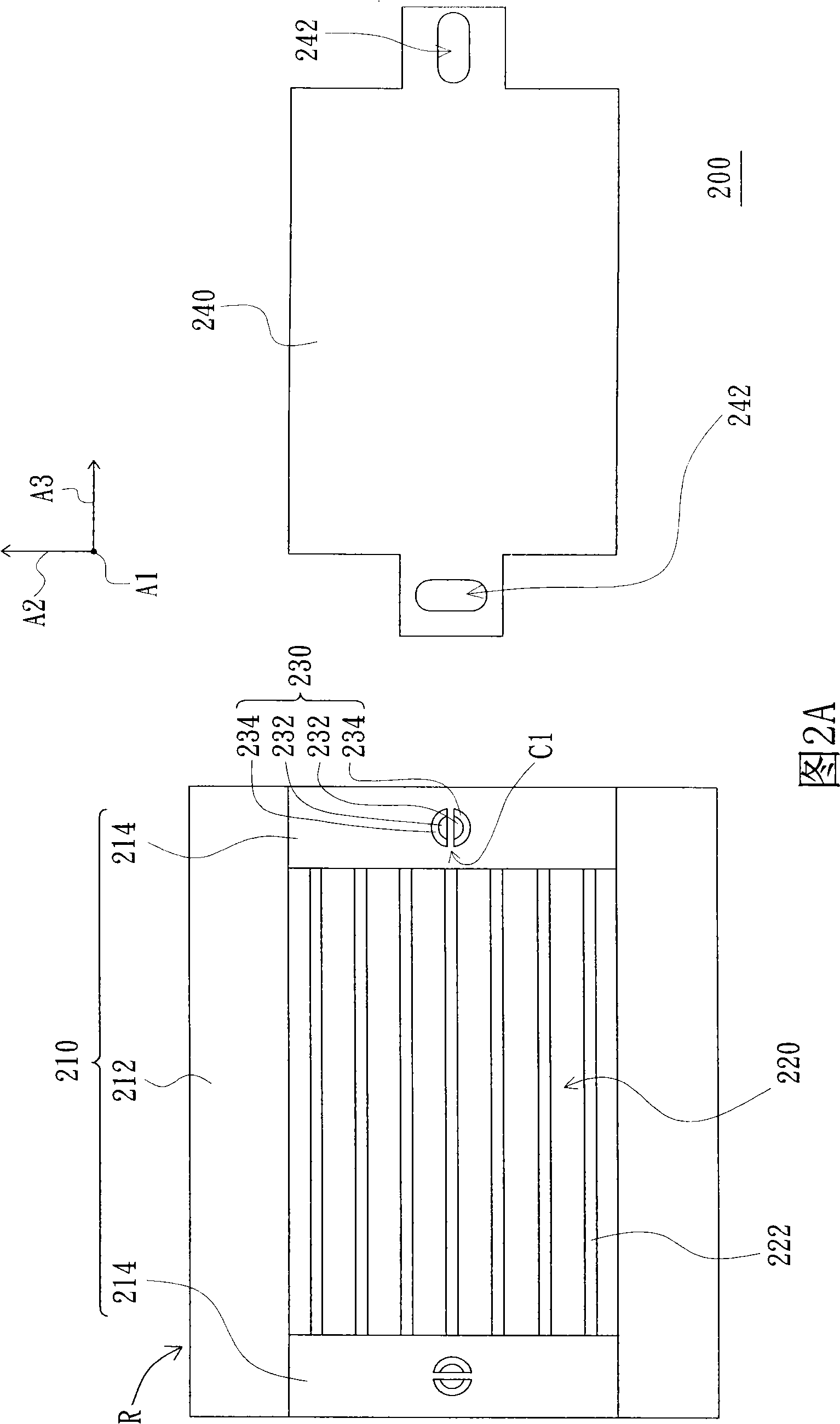

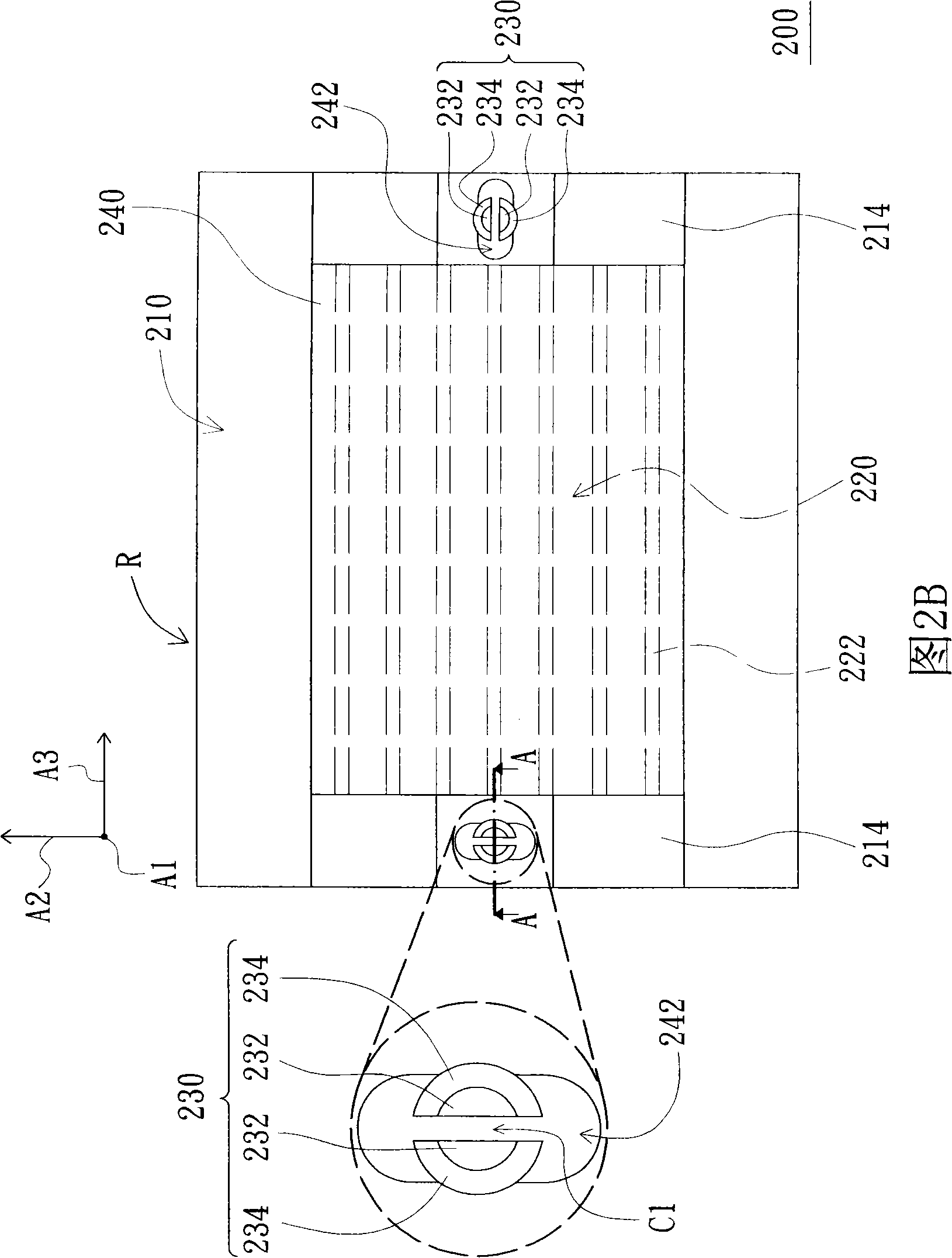

[0050] FIG. 2A is a partially exploded schematic diagram of a backlight module according to the first embodiment of the present invention, and FIG. 2B is a schematic diagram of the combination of the backlight module in FIG. 2A , Figure 2C A schematic cross-sectional view of the backlight module in FIG. 2B along the line A-A is shown. Please refer to Figure 2A, Figure 2B and Figure 2C , the backlight module 200 of this embodiment includes a base 210 , a light source 220 , a plurality of fixing components 230 and at least one optical film 240 . The light source 220 is disposed on the base 210 and is suitable for emitting light. In this embodiment, the light source 220 includes a plurality of lamp tubes 222 arranged in parallel, and the base 210 and the fixing components 230 form a carrier R.

[0051] The base 210 of this embodiment includes a base 212 and two lamp clamping parts 214 . The light tube holders 214 are disposed on opposite sides of the base 212 to hold each ligh...

no. 2 example

[0059] FIG. 4A is a schematic diagram of a combination of a backlight module according to the second embodiment of the present invention, Figure 4B A schematic cross-sectional view of the backlight module of FIG. 4A along the line B-B is shown, Figure 4C A schematic cross-sectional view of the backlight module shown in FIG. 4A along line C-C is shown. Please refer to Figure 4A, Figure 4B and Figure 4C , the difference between the backlight module 300 of this embodiment and the backlight module 200 of the first embodiment is that, Figure 3A The appearance of the fixing assembly 330 on the left in FIG. 2 is different from that of the fixing assembly 230 on the left in FIG. 2 .

[0060] Each flexible connection part 332 of the fixing component 330 on the left in FIG. 4A has at least one pair of flexible connection parts 332 a (only one pair is schematically shown in FIG. 4A ), which is connected to the base 310 . Each buckle 334 of the left fixing component 330 in FIG. 4...

no. 3 example

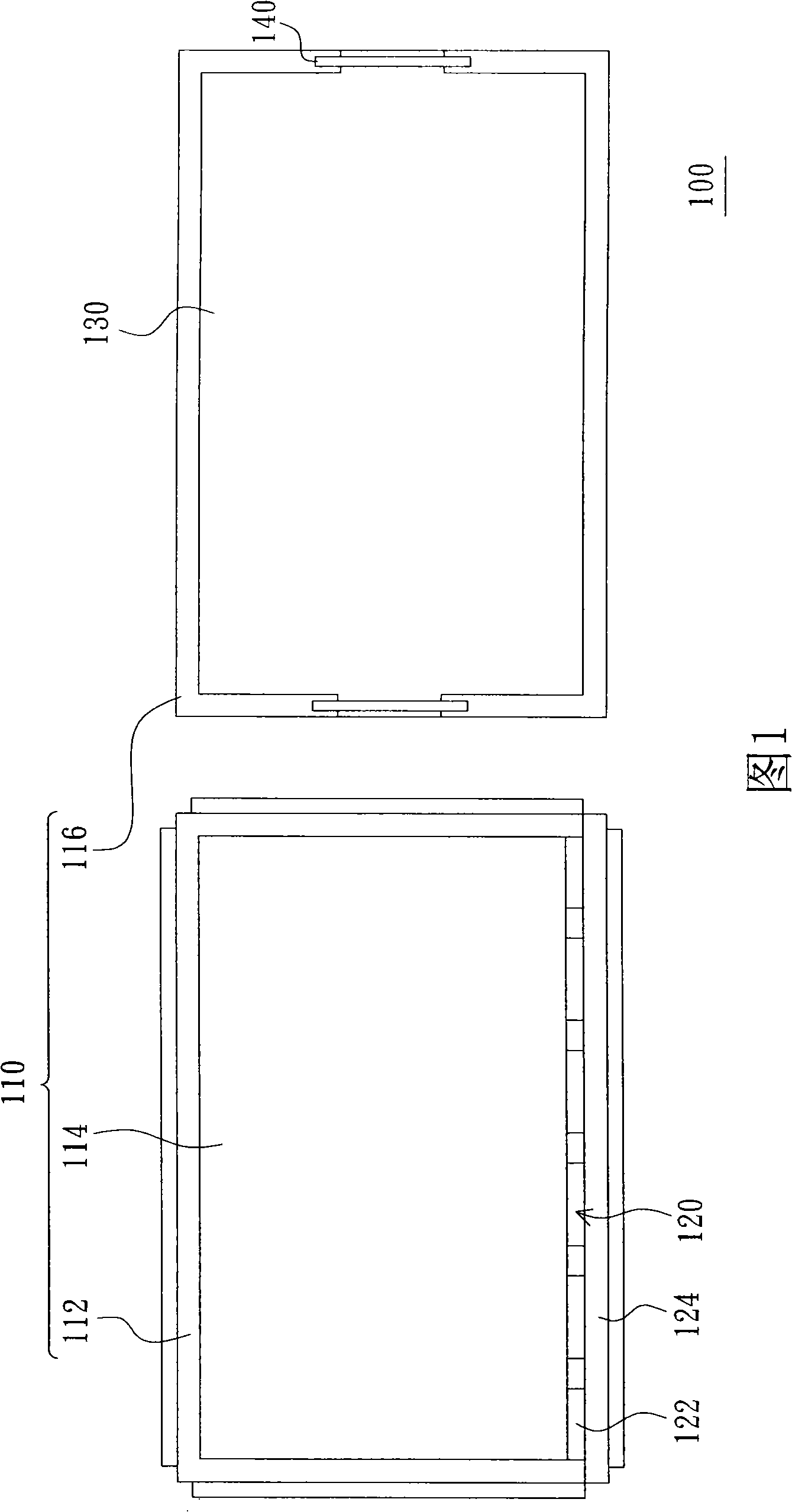

[0063] FIG. 5 is a partially exploded schematic diagram of a backlight module according to a third embodiment of the present invention. Please refer to FIG. 5 , the base 410 of the backlight module 400 of this embodiment includes a base 412 , a light guide plate 414 and a frame 416 disposed on the base 412 . The light guide plate 414 is disposed on the base 412 , and the light source 420 includes a plurality of LED devices 422 and a circuit board 424 . The LED devices 422 are electrically connected to the circuit board 424 , and the light source 420 is disposed on the base 412 and located beside the light guide plate 414 . The flexible connectors 432 of each fixing component 430 are disposed on the frame body 416 . After the backlight module 400 is assembled (not shown), the frame body 416 is disposed on the base 412 , and the optical film 440 covers the light guide plate 414 .

[0064] In summary, the embodiments of the present invention have at least the following or other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com