Fixing method for needle selecting device driving coil

A technology for driving coils and fixing methods, which is applied in the direction of electromagnets, etc., and can solve problems such as coil burnout, complicated manufacturing process of coil seat covers, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Referring to the above figures, the following examples are provided. Examples will help to understand the present invention, but do not limit the content of the present invention. All deformations that can be directly derived or associated by those skilled in the art from the content disclosed in the present invention should be considered as the protection scope of the present invention.

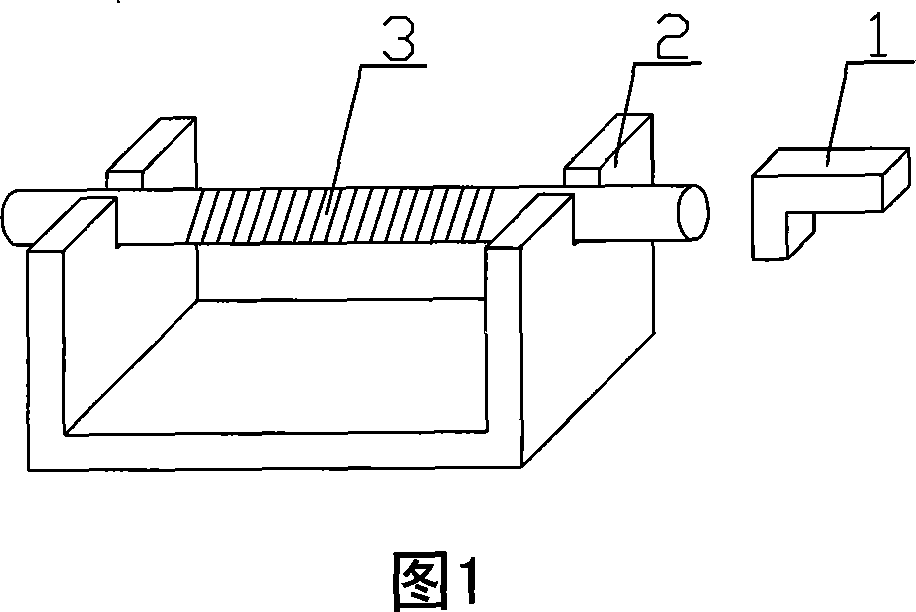

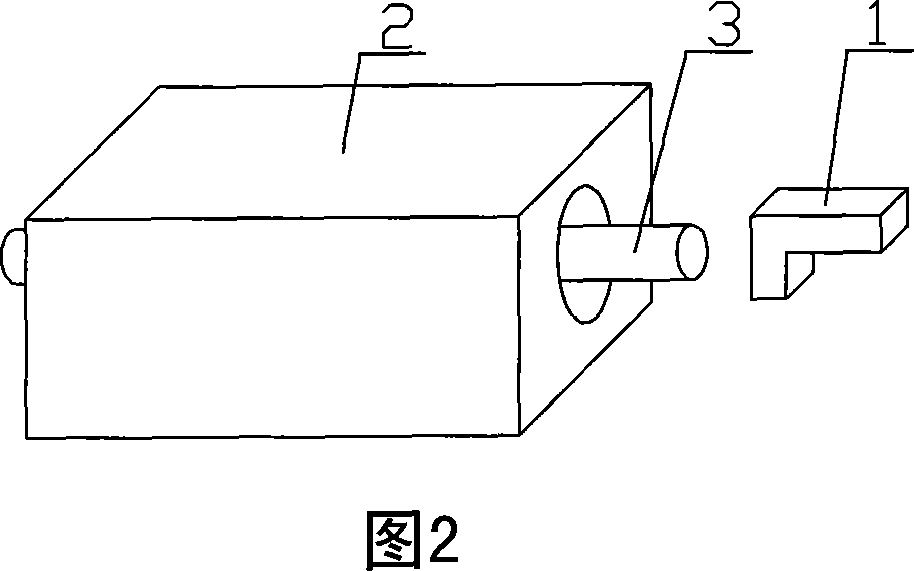

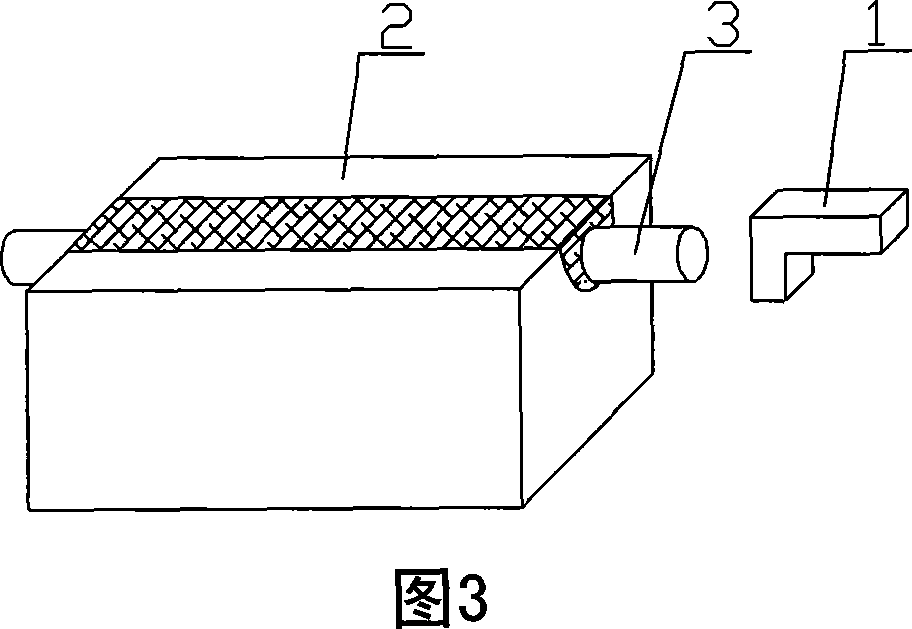

[0014] In this method for fixing the driving coil of the needle selector, the driving coil 2 that controls the movement of the blade 1 of the needle selector is installed on the coil seat 3 and is fixedly connected with it. The steps of this method include: manufacturing the coil base 3 with grooves on the surface in advance, putting the driving coil 2 into the groove of the coil base 3, and then filling the groove with glue.

[0015] The jelly is made of insulating resin varnish. The manufacturing method of the coil base 3 is direct casting. The cross section of the groove is a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com