Automatic grease injection mechanism for outer frame of slide track

A technology of outer frame and slide rail, applied in the direction of engine components, mechanical equipment, engine lubrication, etc., can solve the problems of oil leakage and oil leakage in the oil circuit, and achieve the effect of strong adaptability, quick type change and good contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

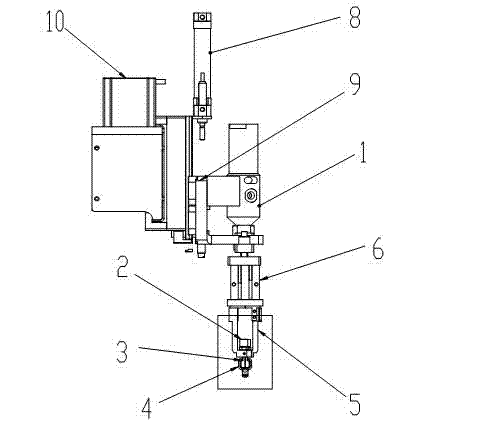

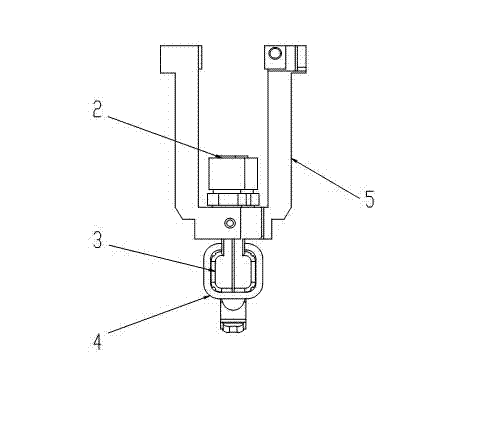

[0017] Such as figure 1 , figure 2 As shown, the automatic grease injection mechanism for the outer frame of the slide rail includes a cylinder 8, an air claw 6, and a grease nozzle 3. The cylinder 8 is driven and connected to the mobile frame 9, and the air claw 6 is installed on the mobile frame 9, and the grease nozzle 6 is passed through the air claw 6. The bracket 5 is equipped with two nozzles 3 symmetrically distributed left and right. The shape of the two nozzles matches the internal shape of the outer frame 4 of the slide rail. The four corners of the two nozzles distributed at 90 degrees are provided with injection holes. , the diameter of the oil injection hole is 0.2mm, the grease pipeline of the oil supply system 10 is connected with the oil nozzle 3 through the oil valve 1, the oil supply system 10 includes the ARM grease pump and the motor connected to it, and the oil valve 1 is an EFD oil valve, The grease pipeline is connected with the grease nipple 3 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com