Improved heat storage system

A heat storage and storage container technology, applied in the direction of electric energy storage systems, indirect heat exchangers, heat exchanger types, etc., can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

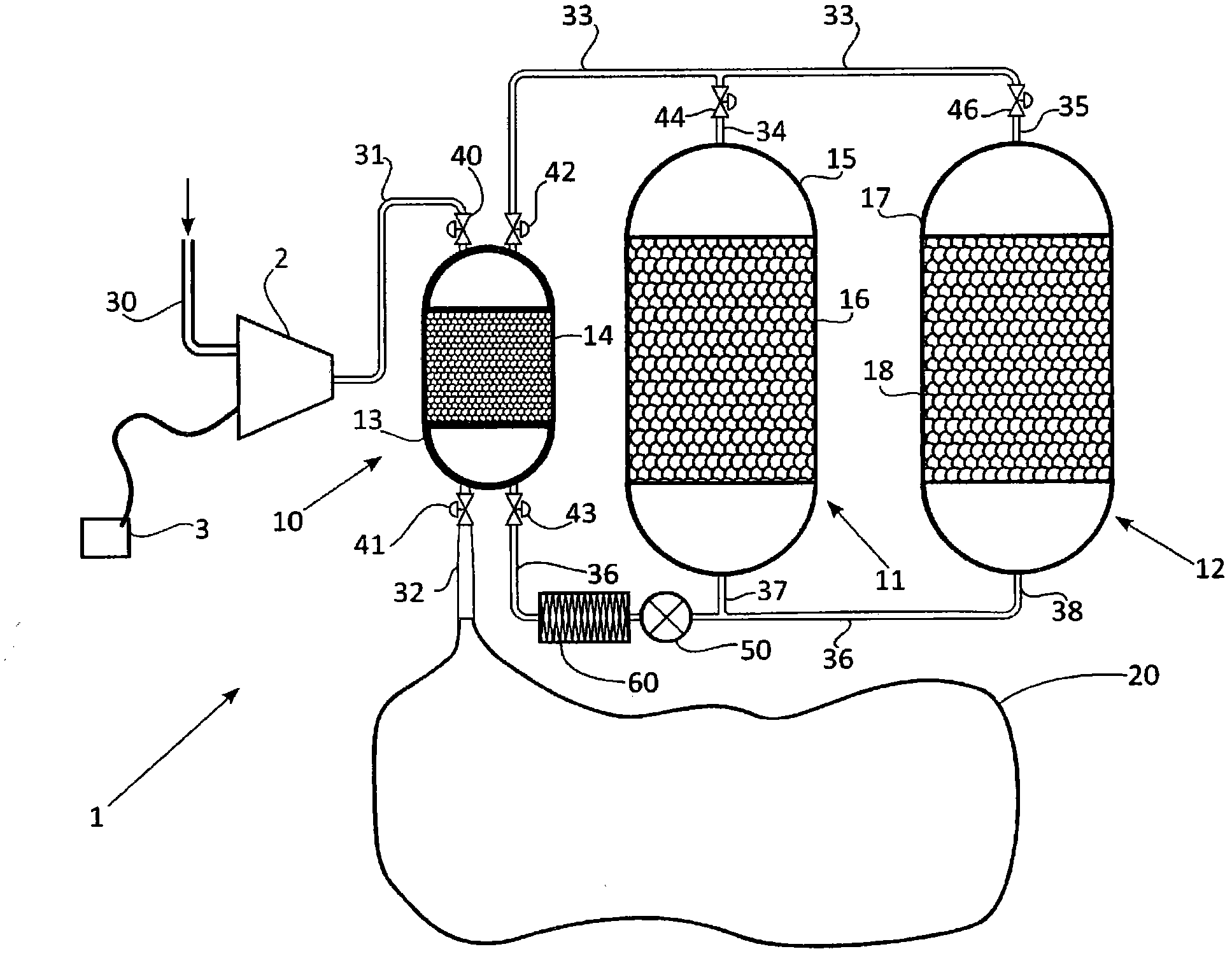

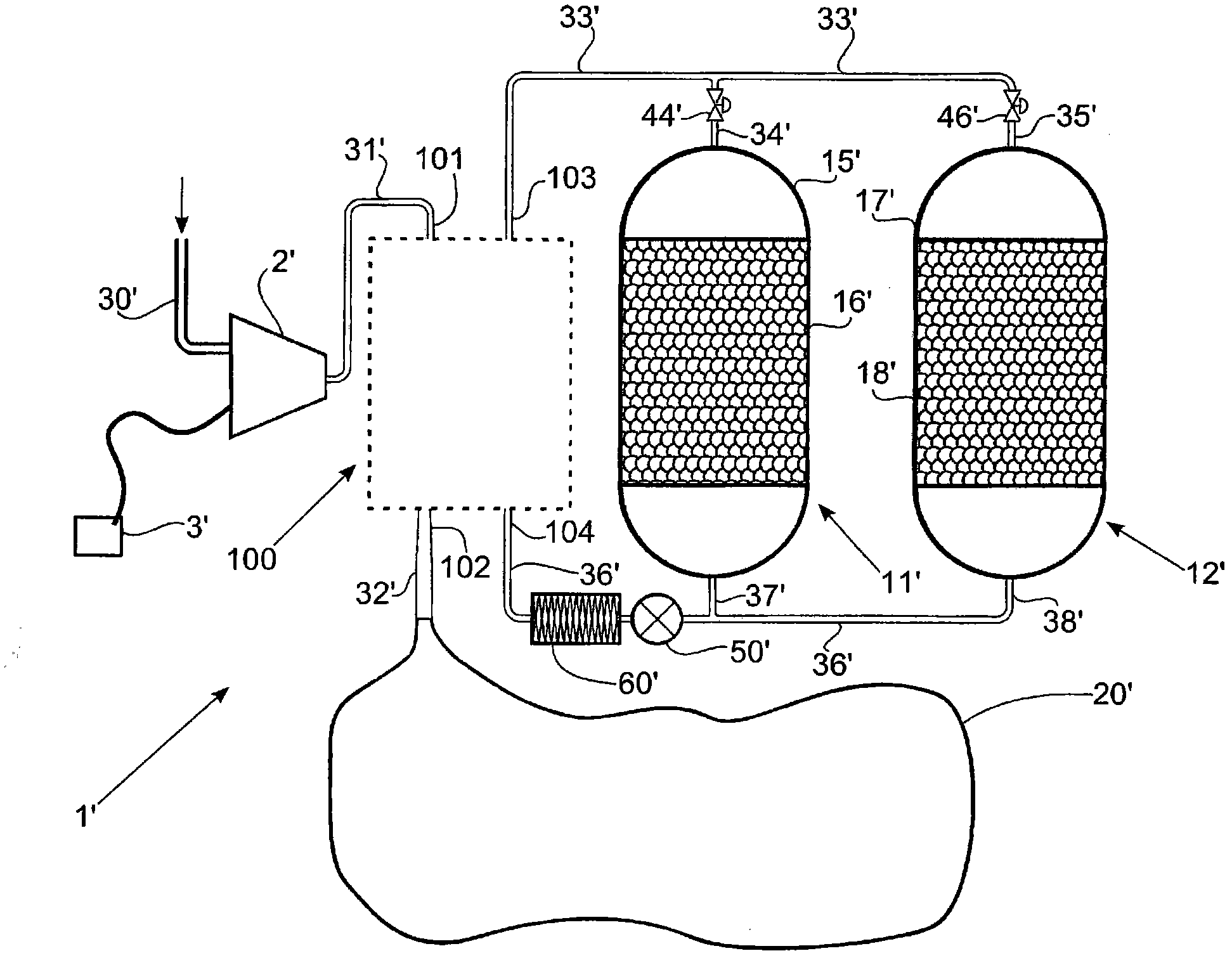

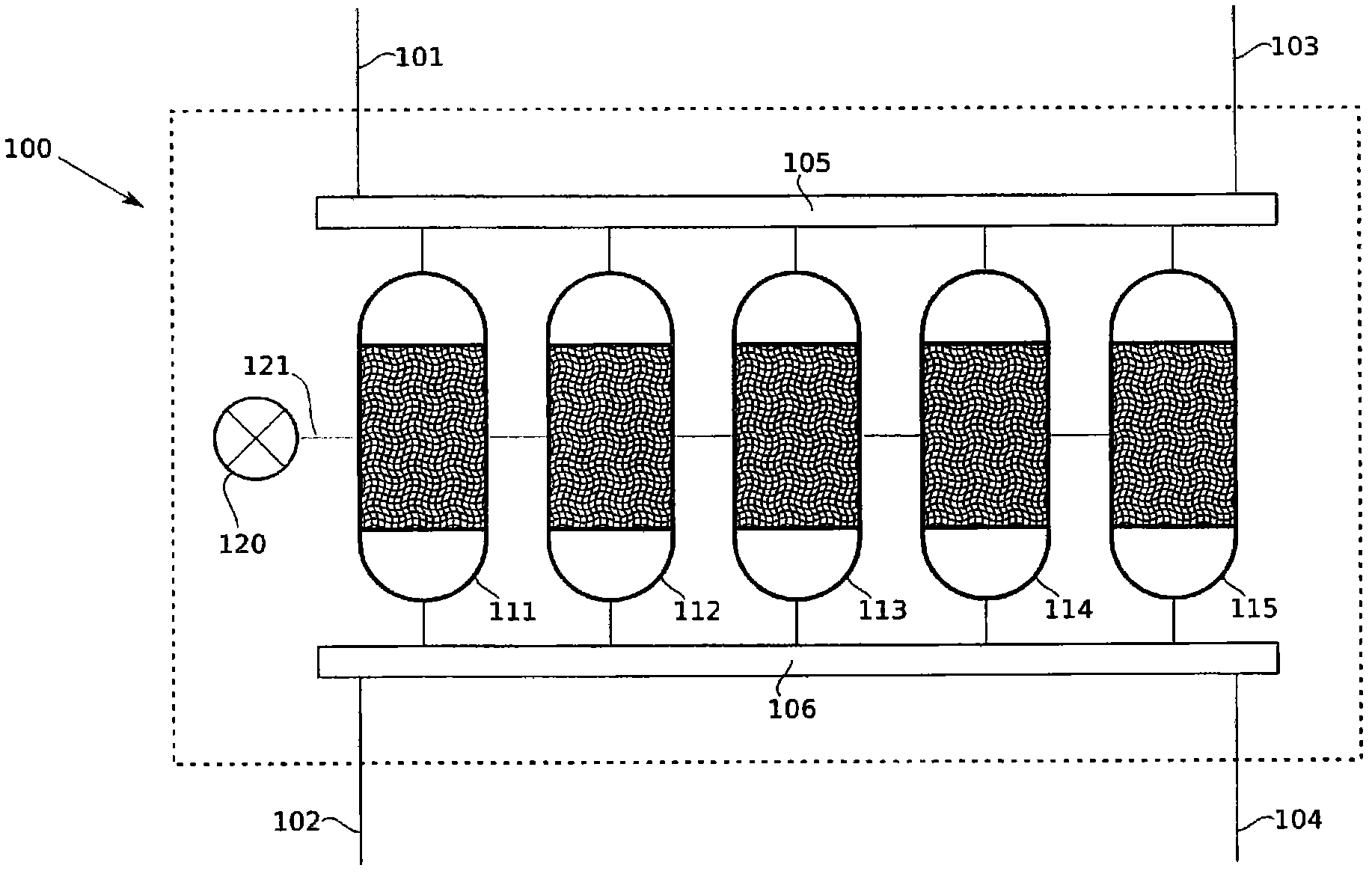

[0134] figure 1 An electrical storage system 1 is shown comprising a compressor / expander (eg compressor / expander turbine) 2 and a gas storage 20 powered by a power source 3 and connected to a high pressure thermal storage 10 . The high-pressure thermal store 10 is in turn connected to low-pressure thermal stores 11 and 12 . Air enters and leaves the system through duct 30 and passes via ducts 31 , 32 , 33 , 34 , 35 , 36 , 37 and 38 . Valves 40, 41, 42, 43, 44 and 46 can be used to selectively close / open the different conduits. An air pump 50 is connected to conduit 36 and can pump air in either direction. Heat exchanger 60 is used to maintain the temperature of the gas passing through conduit 36 at substantially ambient temperature or a fixed base temperature.

[0135] The high-pressure thermal store 10 comprises an insulated high-pressure vessel 13 with a thermal matrix 14 through which the compressed gas can pass and transfer its heat when inflated and from which it r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com