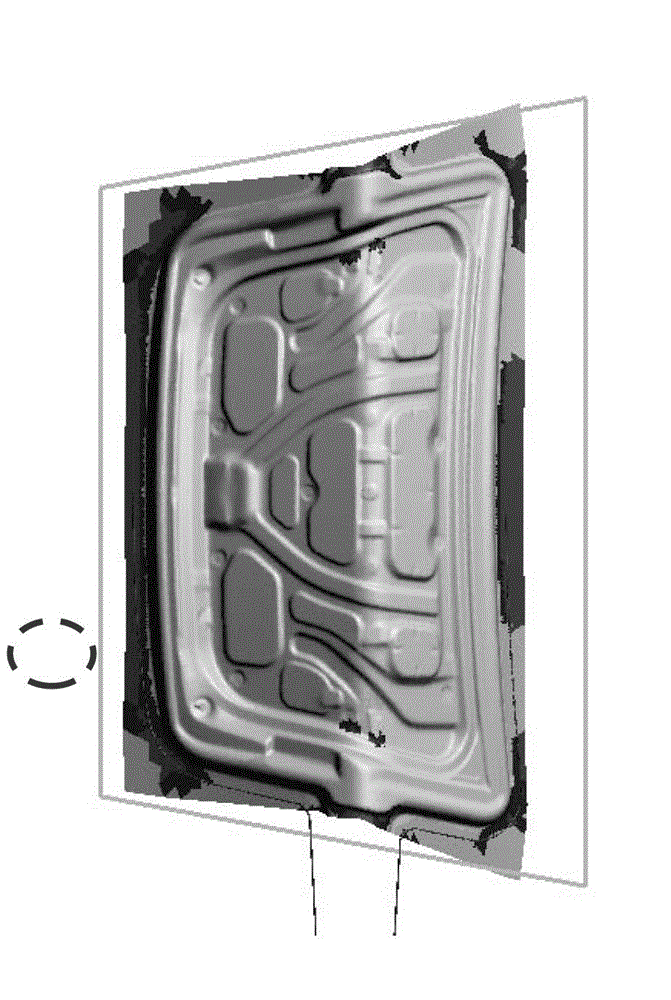

Method for forming tail door inner plate die surface

A surface forming and plate die technology, applied in the field of inner plate die surface forming of the tailgate, can solve problems such as large surface defects, and achieve the effect of reducing the size of the blank and improving the utilization rate of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

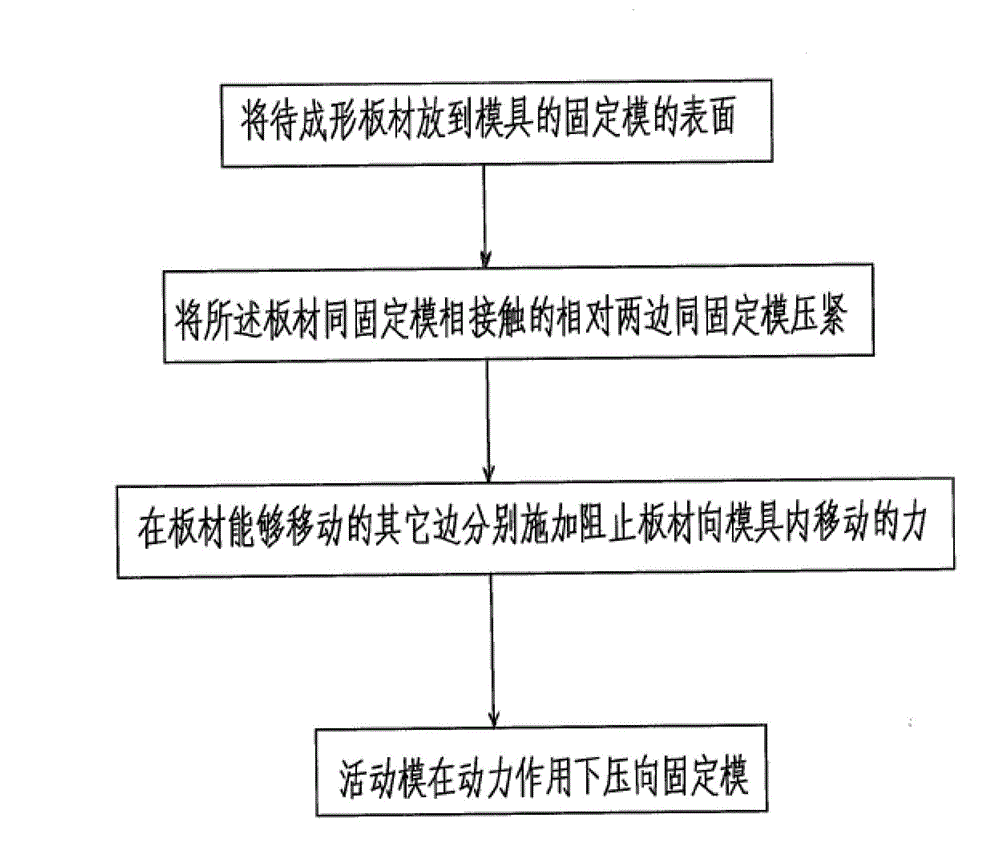

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0022] The wrinkle-prone parts mentioned in the present invention refer to the parts that are wrinkled in the existing technology or production process, such as the lower corners of the inner and outer panels of the door, and the front ends of the upper pillars on the side wall. This part belongs to the main defect in the actual production , those skilled in the art all understand the problem of this position.

[0023] The remaining meat mentioned in the present invention refers to the accumulation formed at the bend after bending relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com