Multifunctional wiring harness frame

A multi-functional, wire harness technology, applied in the field of wire harness processing, can solve the problems of intertwined and entangled cables, unbalanced force on the support frame, unsafe hidden dangers, etc., to achieve increased safety, stable structure, and a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

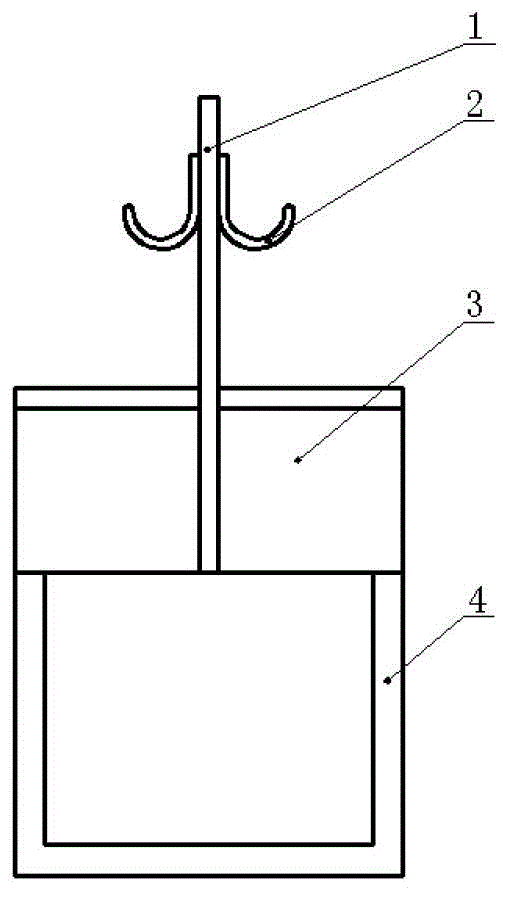

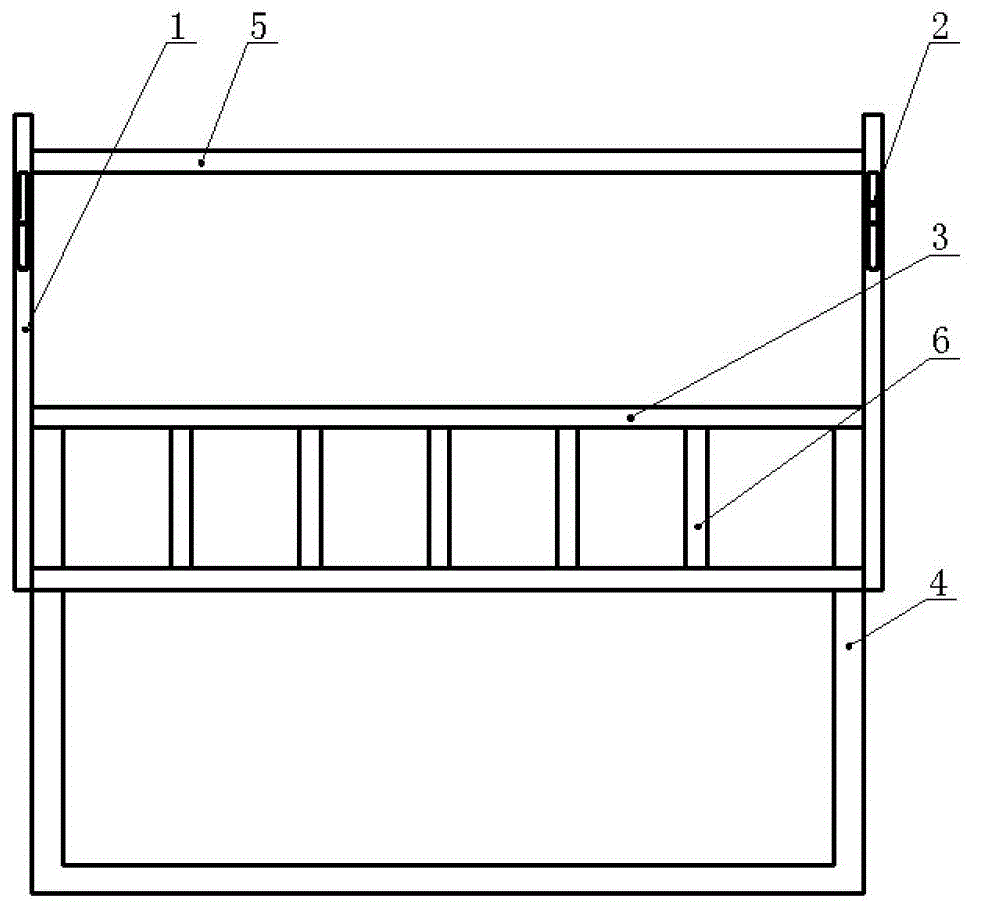

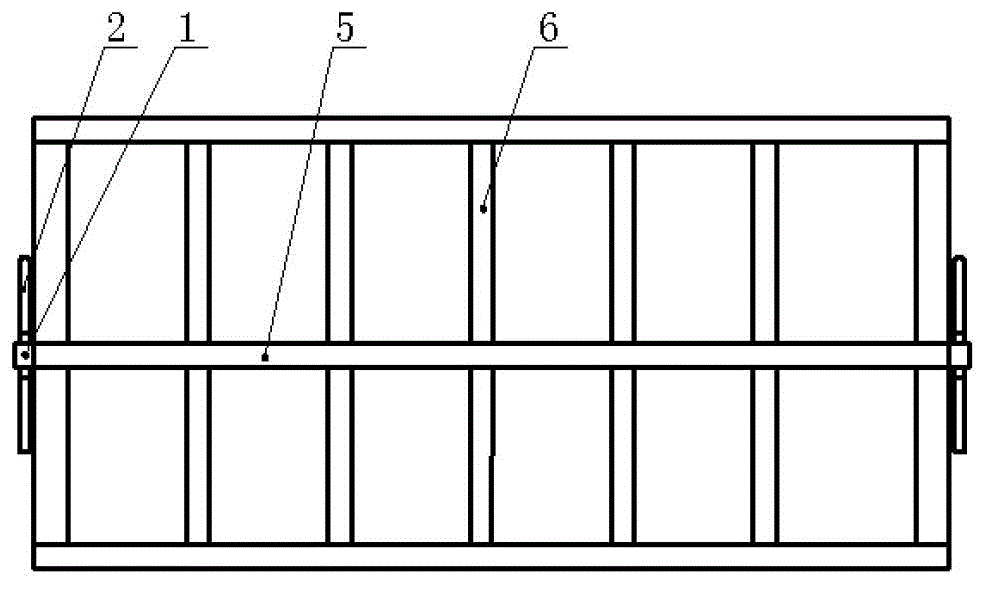

[0014] A multi-functional wire harness rack, including a bracket 4, a trunking box 3, a column 1 and a beam 5, such as Figure 1 to Figure 3 As shown, the trunking box is coaxially fixed on the upper end of the bracket, and a column is fixed on the outer wall of the trunking box on both lateral sides coaxially and symmetrically. A horizontal beam is fixed horizontally on the upper part of the column between the columns on both sides. Various wiring harnesses.

[0015] In order to facilitate the hanging of the wiring harness, a hook 2 is fixed symmetrically on the top of the uprights on both sides. In this embodiment, there are two hooks on the uprights on each side.

[0016] In order to facilitate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com