TBM (tunnel boring machine) bidirectional rotary tapping cutter head and production process thereof

A technology of bidirectional rotation and manufacturing process, applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of large stratum disturbance, difficulty in correcting deviation, affecting the driving speed, etc., to reduce the number of abnormal shutdowns, convenient assembly and maintenance, The effect of improving the driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

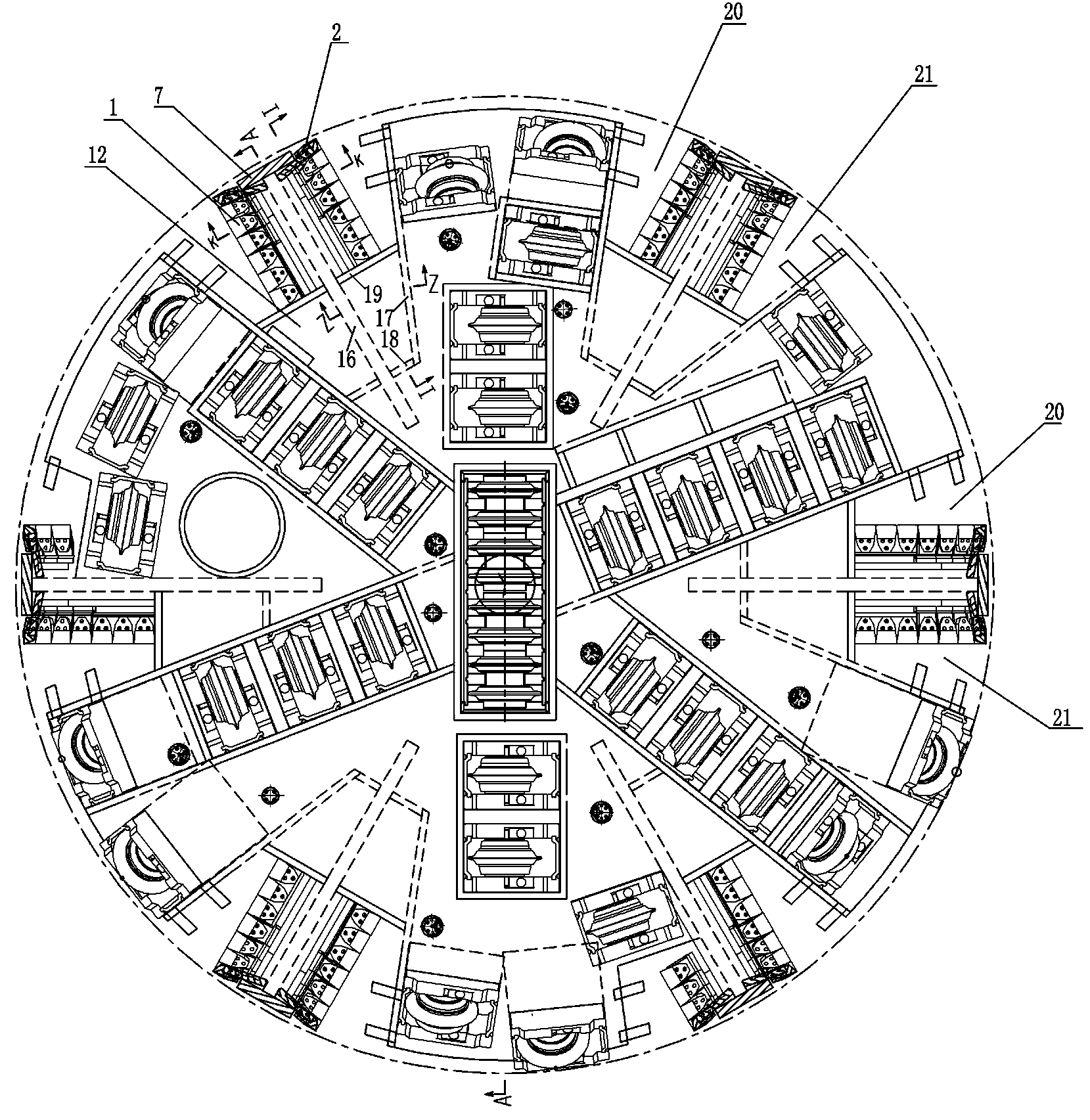

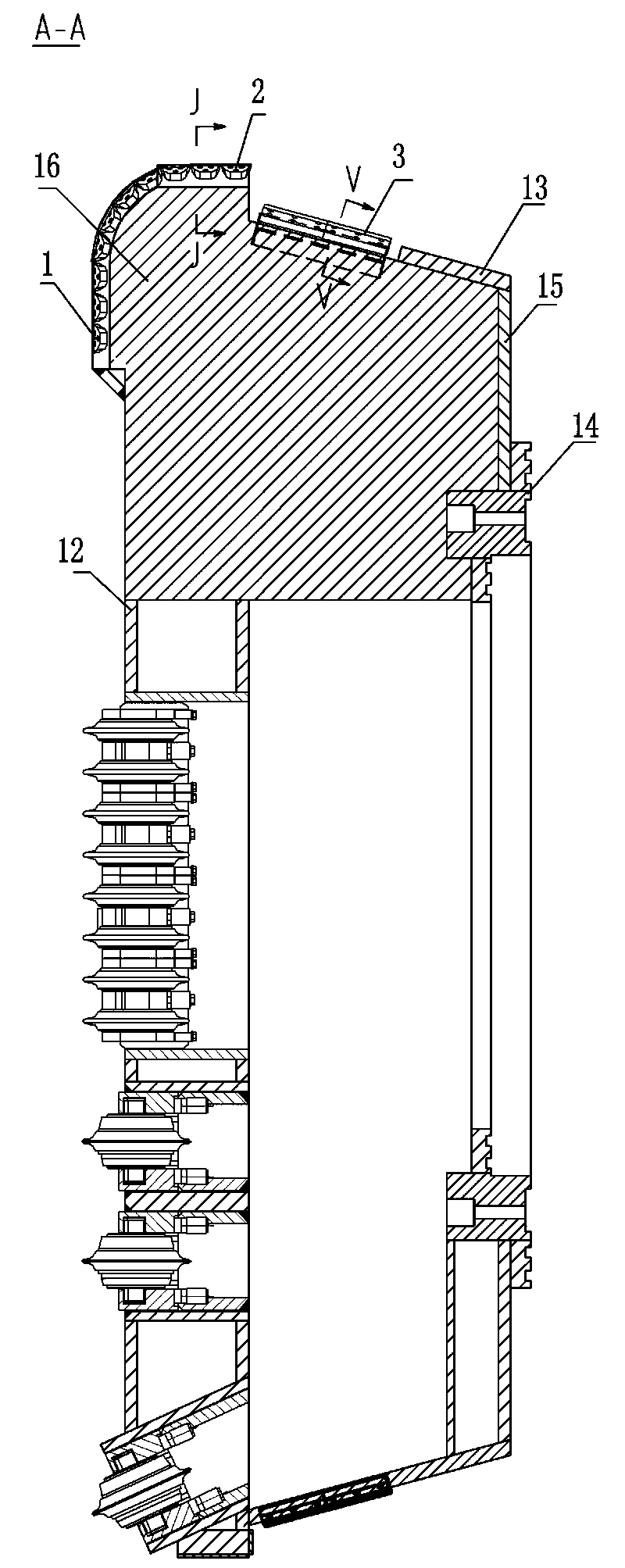

[0039] Embodiment 1: A kind of TBM two-way rotating slag cutter head, see figure 1 , 6 pairs of slag inlets are evenly distributed on the circumference edge of the disc body 12 of the cutter head assembly, which are 6 positive rotation slag inlets 20 and 6 reverse rotation slag inlets 21 respectively.

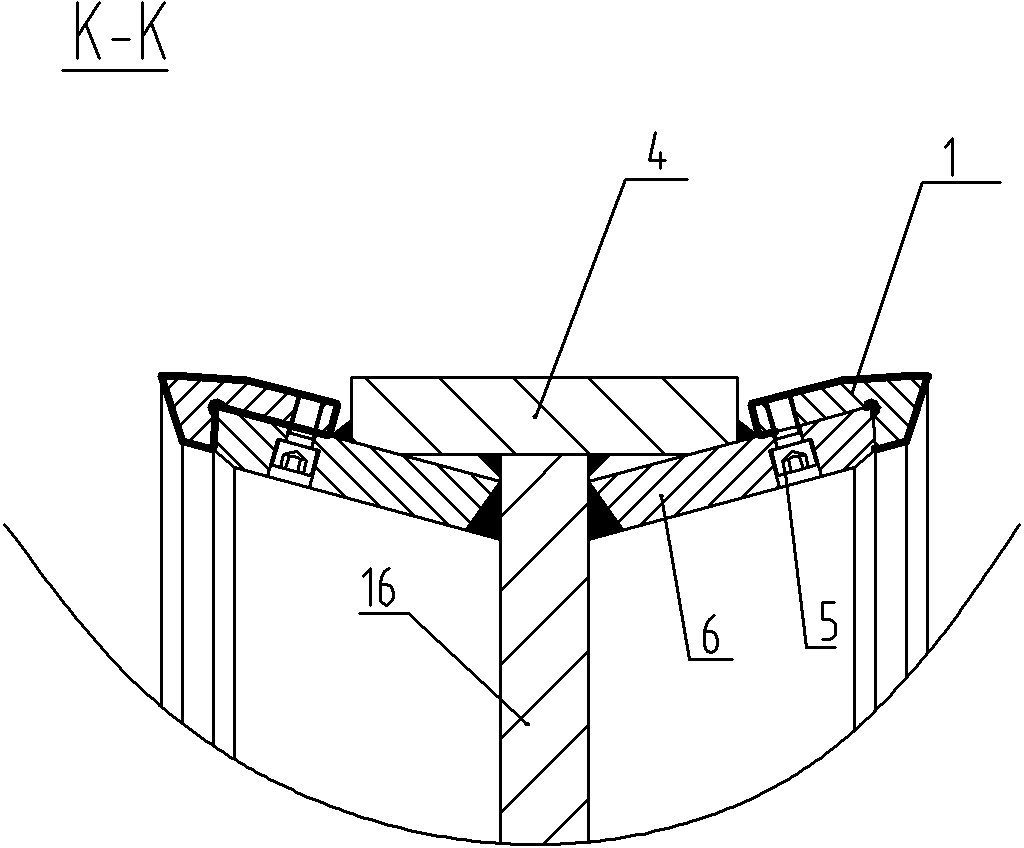

[0040] The middle part of each pair of slag inlets is provided with a slag sliding board 16 , and the slag sliding board 16 is arranged radially and welded on the inner wall of the disc body 12 . Every pair of slag inlets takes the slag sliding plate 16 as the center of symmetry. When the disc body 12 rotates in the forward direction, the 6 forward rotation slag inlets 20 work, and when the disc body 12 rotates in the reverse direction, the 6 reverse rotation slag inlets 21 work.

[0041] The upper end and the peripheral area of the slag sliding board 16 slightly exceed the outer edge of the disc body 12 respectively, the upper end of the slag sliding board is a straight se...

Embodiment 2

[0047] Example 2: see Figure 1 to Figure 7 , a TBM two-way rotating slag cutter head manufacturing process, comprising the following steps:

[0048] (1) There are 6 slag inlets evenly distributed around the edge of the disc body 12 of the cutter head assembly, and 6 slag sliding plates 16, 6 conical plates 13, 6 bottom cover plates 15 and 1 bottom Connection flange. Pre-assemble the slag slag plate 16, the conical plate 13, the bottom cover plate 15 and the connecting flange 14 respectively, and check the key dimensions at the same time to ensure accurate assembly positioning; the assembly relationship is as follows:

[0049] Slag sliding plate 16: a slag sliding plate is installed in the middle of the above six slag inlets in the radial direction, and a positive rotation slag inlet and a reverse rotation slag inlet are respectively formed on both sides of each slag sliding board. The upper end of the slag sliding board is a straight section, and the outer side of the slag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com