Muck stirring monitoring device and stirring detection method thereof

A monitoring device and dregs technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problem of not being able to understand the internal conditions of the excavation cabin in real time and accurately, and the inability to intuitively judge the mud cake of large-sized foreign objects in the dregs, which affects the excavation To reduce the number of abnormal shutdowns, reduce the total time of cabin entry, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0042] Embodiment 3: A roadheader, including the muck mixing monitoring device described in Embodiment 2, used for monitoring the muck in the excavation cabin during tunnel excavation, so as to facilitate timely adjustment of the parameters of the modifier and ensure the excavation Machine efficient excavation. The high-pressure water system can be set on the rear supporting trailer.

Embodiment 4

[0043] Embodiment 4: A stirring detection method of a slag stirring monitoring device, the steps are as follows:

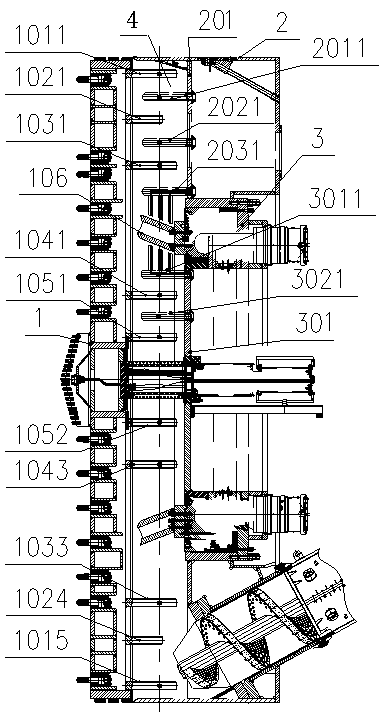

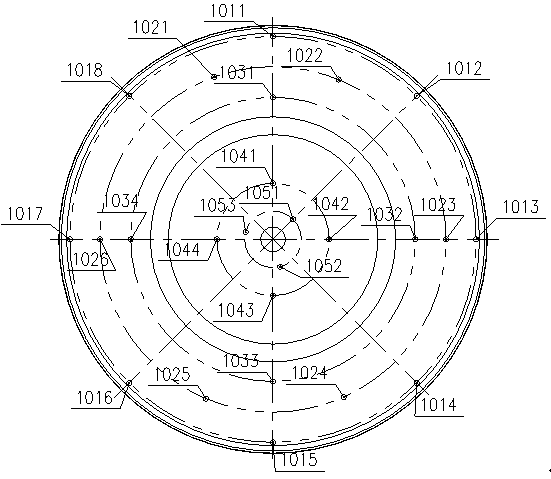

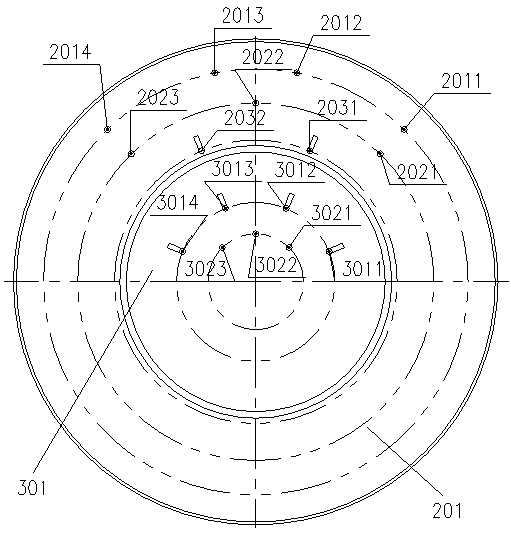

[0044] S1: Set an active stirring rod on the back of the cutter head 1, and set a passive stirring rod on the rear bulkhead of the excavation cabin 4. The active stirring rod and the passive stirring rod are located on concentric circles with different diameters, and the active stirring rod and the passive stirring rod Stress sensors 501 are arranged on the rods; the stress sensors 501 are connected to the host computer, and a display module is connected to the host computer; the data measured by the stress sensors can be displayed in real time on the interface of the display module of the host computer;

[0045] S2: During the excavation process, the main drive 3 installed in the shield body 2 drives the cutter head 1 to rotate, and the active stirring rod and the passive stirring rod perform stirring detection on the muck in the excavation cabin 4; The stress mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com