Automatic paper cutting mechanism for printer

A printer, automatic technology, applied in the direction of printing device, printing, etc., can solve the problems of manual cutting, trouble, no printing and paper cutting, etc., to achieve the effect of solving trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

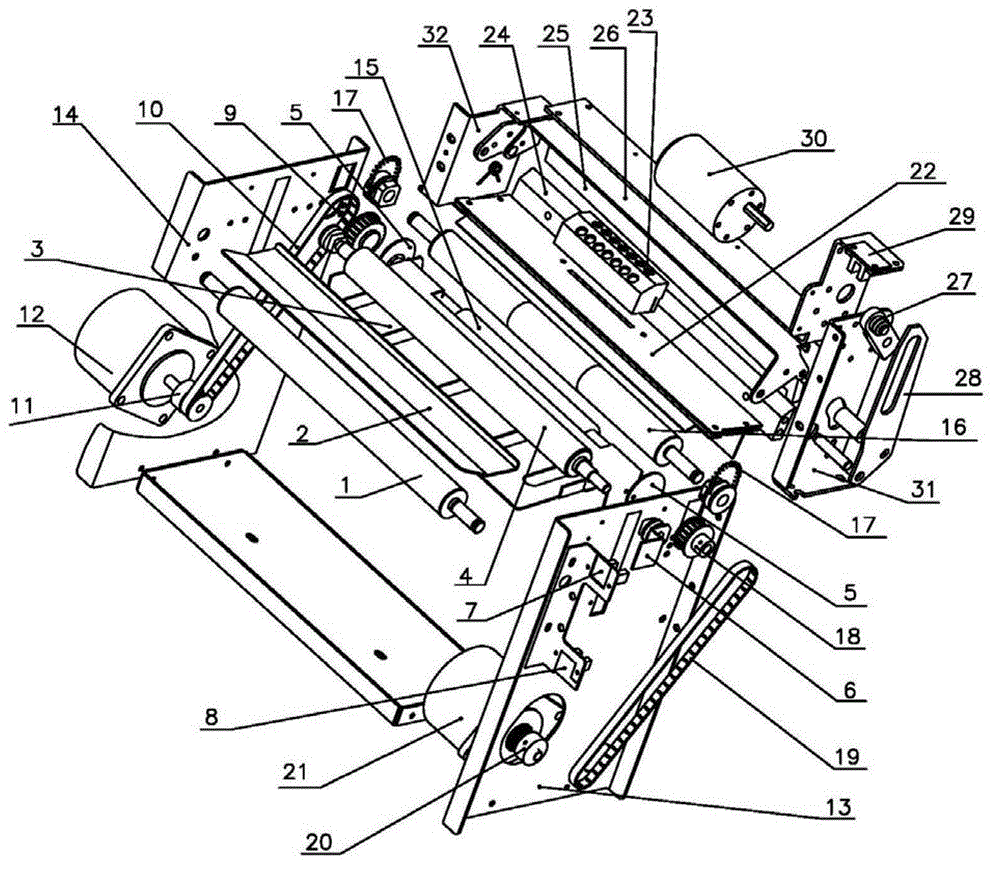

[0024] Such as figure 1 As shown, an automatic paper-cutting mechanism of a printer is installed in front of the paper outlet of the printer. The automatic paper-cutting mechanism includes: a lower paper-feeding guide shaft 1 and a paper-feeding upper guide plate 2, a flap part, a paper-feeding part, and a sensor Bottom plate 22 and reflective photoelectric sensor 23, cutter part;

[0025] The flap part is composed of a rotating flap 3, a pressure guide shaft 4, a left and right cam piece 5, a pressure guide shaft tongue piece 6, an upper photoelectric sensor 7, a lower photoelectric sensor 8, a flap pulley 9, and a flap belt. Wheel drive belt 10, motor belt pulley 11 and turnover plate motor 12 are formed;

[0026] Described paper-feeding part is made up of paper-feeding main shaft 15, paper-feeding upper pinch 16, left and right each upper pinch tension spring 17, paper-feeding pulley 18, paper-feeding pulley conveyor belt 19, motor pulley 20 and paper-feeding motor 21 com...

Embodiment 2

[0031] An automatic paper-cutting mechanism of a printer, the rest of which are the same as in Embodiment 1. The reflective photoelectric sensor 23 has five pairs of irradiation light sources; the sensor base plate 22 has a 5mm narrow slit.

Embodiment 3

[0033] The automatic paper cutting mechanism of the printer of the present invention is installed in the front of the paper output of Epson L801 or EPSON Stylus photo 1390 printers.

[0034] Firstly, choose the width of the roll paper according to the size of the photo. If you are printing a 6-inch by 4-inch photo, then place the roll paper with a width of 6 inches on the paper tray in the printer. At the same time, a set of black and white cutting lines are added between each photo through the software that sends the photos for future cropping and division.

[0035] Before printing the photo, the rotating flap 3 in the present invention stops at the same parallel position as the paper feeding lower guide shaft 1 and the paper feeding upper guiding plate 2, and at the same time, the raised parts at both ends of the rotating flap 3 hold up the guide shaft 4 Make a gap in the middle through the paper. At this time, the pressure guiding shaft tongue 6 is also covered on the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com