A kind of sub-bottling surface printing equipment

A technology of surface printing and sub-packaging, applied in printing, printing presses, rotary printing presses, etc., can solve the problem of wasting paint and other problems, and achieve the effect of cost saving, convenient operation and reduction of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

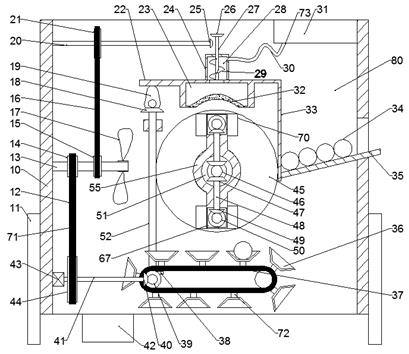

[0014] Combine below Figure 1-3 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

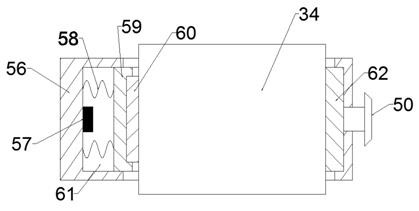

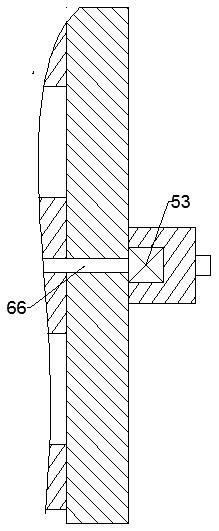

[0015] refer to Figure 1-3 , according to an embodiment of the present invention, a bottle surface printing device includes a main body 10, a working chamber 80 is opened in the main body 10, and a turntable 45 is rotated in the working chamber 80, and the turntable 45 A clamp mechanism 70 is provided inside, and the clamp mechanism 70 clamps the sub-package bottle 34. One side of the turntable 45 is provided with a fan mechanism 71, and the fan mechanism 71 dries the printed sub-package bottle 34. The top of the turntable 45 is provided with a printing mechanism 73, and the printing mechanism 73 prints the sub-package bottles 34. The bottom of the turntable 45 is provided with a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com