Photocuring 3D printing device and printing method thereof

A 3D printing and light curing technology, applied in the field of 3D printing, can solve the problems of limited model printing speed, large separation force, and deformation of the solidified model, so as to avoid deformation of the fixed model, reduce separation force, and reduce the bonding area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

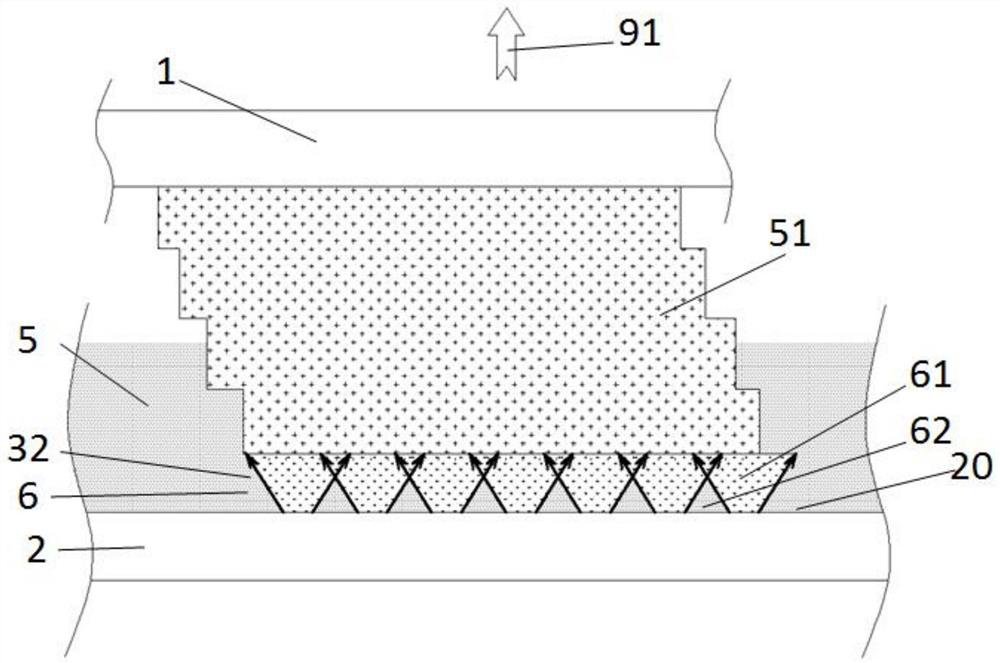

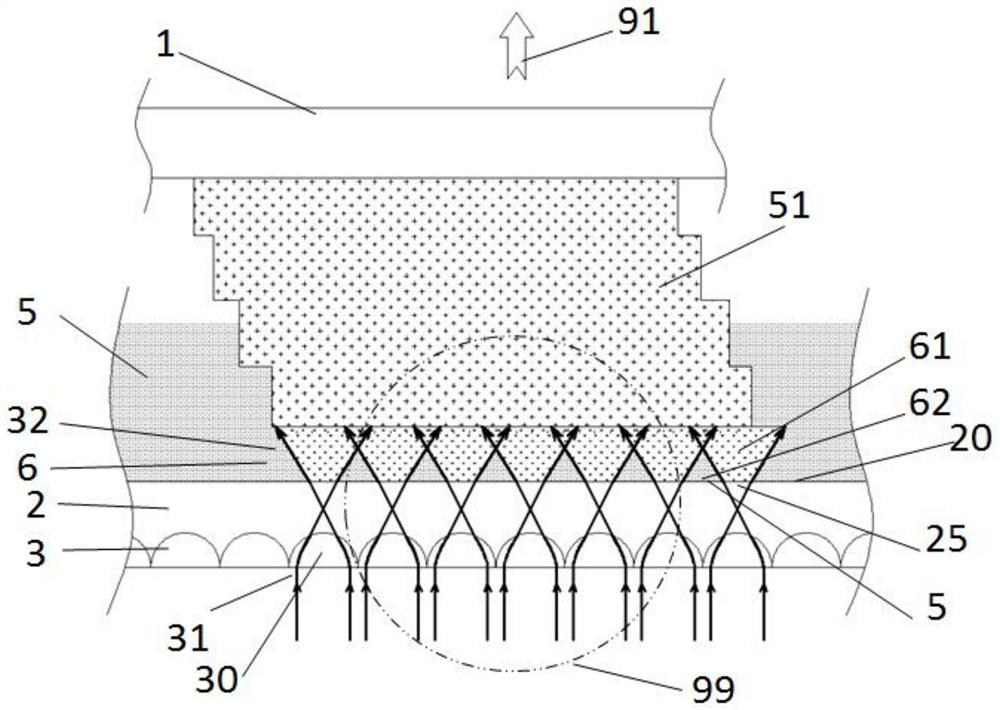

[0083] Such as figure 2As shown, it is illustrated that an optical system 3 (optical system) is formed on the light-transmissive plate 2, and the optical system 3 forms a number of microlens units 30 for the light-transmissive plate 2, and the microlens units 30 are arranged in an array to form a microlens array, The light beams 31 are transformed by the microlens array and emitted from the molding surface 20 of the transparent plate 2 at intervals and diffused to form several beam groups 32 .

[0084] In this embodiment, the optical set 3 adopts a variable refractive index microlens array, that is, several tiny variable refractive index microlens unit arrays are arranged, and the light beam 31 passes through the focus transformation of the variable refractive index microlens array from the light transmission plate 2. Several light beam families 32 are formed by the spaced and expanded emission of the forming surface. The focusing point of the light beam 31 shown in the figu...

Embodiment 2

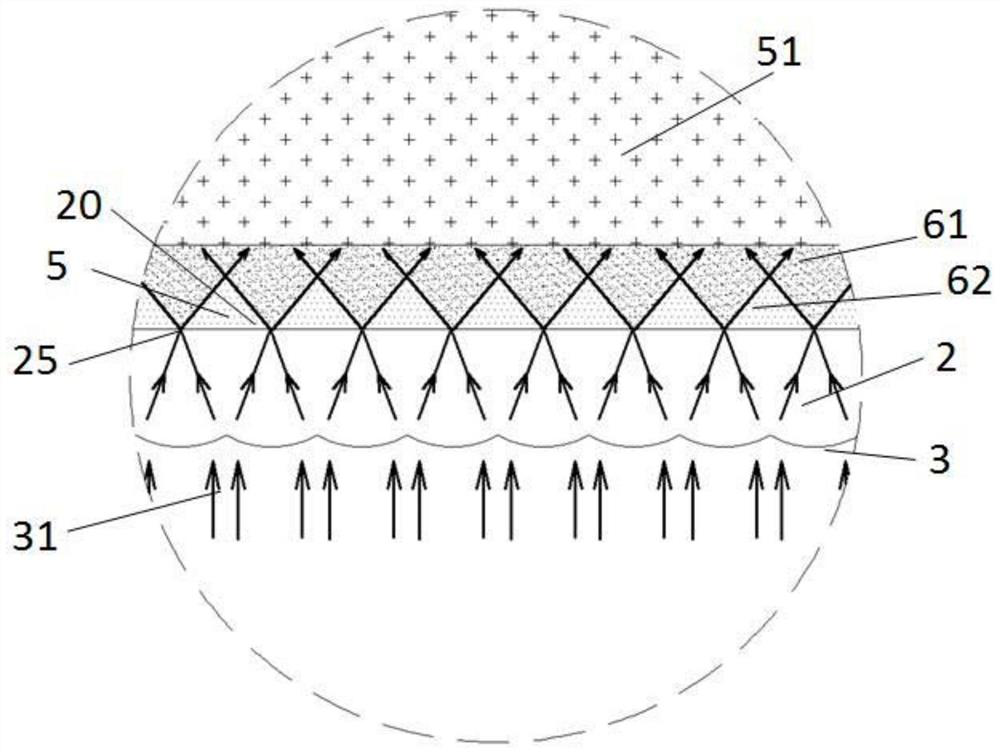

[0086] Such as image 3 It shows that the optical train 3 is formed on the surface of the light-transmitting plate 2, and its schematic position is the same as figure 2 Corresponds to the identification area 99 in. For example, a semi-convex lens array can be provided on the other side of the light-transmitting plate 2 opposite to the molding surface 20 , and the light beams 31 are focused by the semi-convex lens array and emitted from the molding surface 20 of the light-transmitting plate 2 at intervals and diffused to form an arrayed beam group 32 .

[0087] The figure also shows that by setting the focal point of the optical train 3 (that is, the focal point of the light beam 31) on the molding surface 20 of the light-transmissive plate 2, the light-transmitting area 25 can be shrunk into a very small area, even a single Points, the light beam 31 is emitted from the light-transmitting plate 2 and expands to form several beam groups 32 , and irradiates the printing materia...

Embodiment 3

[0090] Such as Figure 4 As shown, it is illustrated that the optical train 3 may be a discrete component independent of the light-transmitting plate 2, and the two are assembled together to realize beam conversion. The optical system 3 is arranged on the irradiation path of the light beam 31. It is shown in the figure that the optical system 3 is formed with microlens units arranged in an array. For example, the planar array of tiny convex lenses is used as an example in the figure. After transformation, the light beams 32 are separated and diffused from the molding surface 20 of the light-transmitting plate 2 to form an arrayed beam group 32 . The microlens array formed by the optical train 3 may be a variable refractive index planar microlens array, or a microconvex lens array, or a microconcave lens array. The optical train 3 can also be different light beam adjustment devices or combinations such as refracting mirrors, reflecting mirrors, diffractive mirrors or gratings....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com