Radiating device

A technology of heat dissipation device and heat dissipation fin set, which is applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc., can solve the problems of limited thermal contact area and unsatisfactory heat dissipation effect, and achieve good heat dissipation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

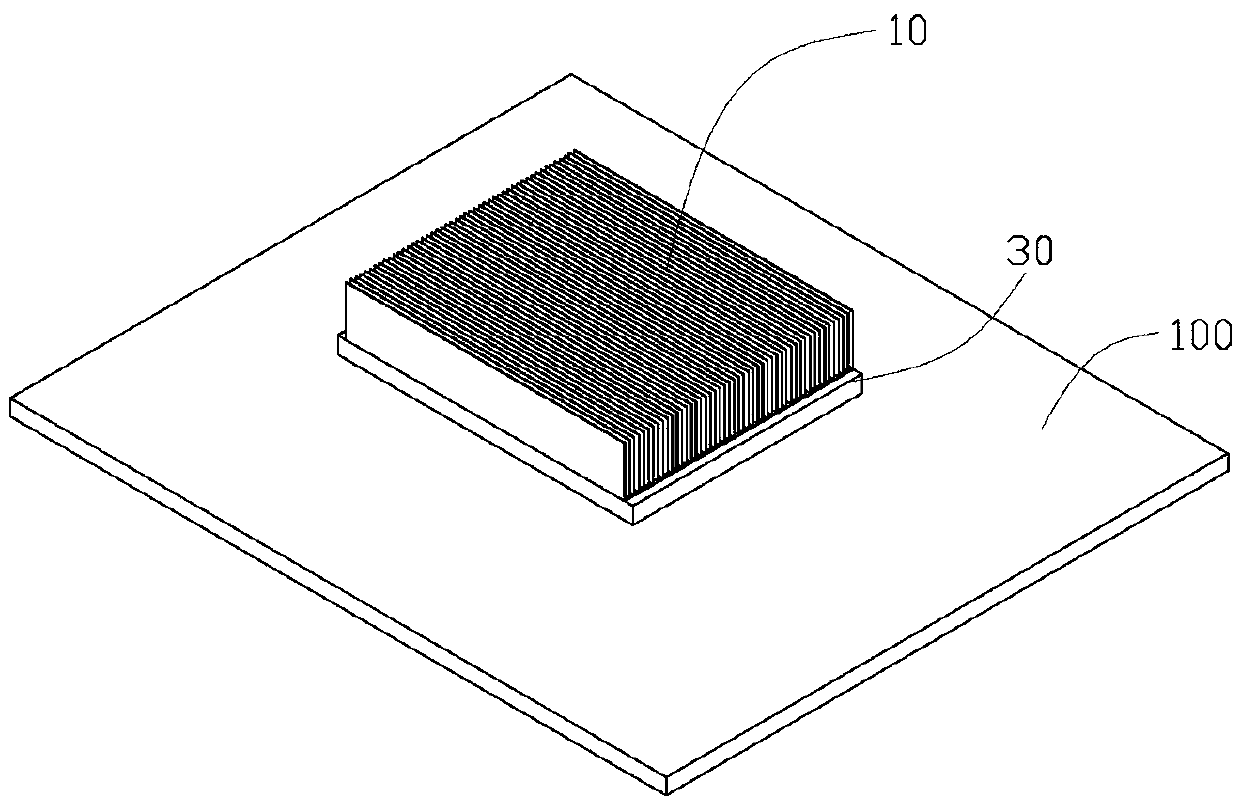

[0021] The embodiment of the present invention relates to a heat dissipation device, which can be applied to electronic devices, such as desktop computers, servers, etc., to dissipate heat from heat-generating electronic components. The heat dissipation device can be used in conjunction with other auxiliary heat dissipation elements, such as a wind guide cover, a fan, etc., to achieve better heat dissipation effects.

[0022] see figure 1 , in one embodiment, a heat dissipation device can be installed on a computer motherboard 100 for dissipating heat from a heating element 110 . The heating element 110 can be a CPU, a south bridge chip, a north bridge chip and the like. The heat dissipation device includes a heat dissipation fin set 10 , a base 30 and a heat pipe 50 mounted on the base 30 .

[0023] The base 30 is flat. The base 30 can be rectangular. The base 30 includes a first contact surface 31 for contacting the heating element 110 and a second contact surface 33 opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com