CO2 flow extraction process for reducing tar and harmful components of tobacco

An extraction and tobacco technology, applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of reducing the aroma of cigarettes, poor coke reduction ability of expanded cut tobacco and expanded cut stems, harm to human health, etc., and achieves safe extraction agent and simple process. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

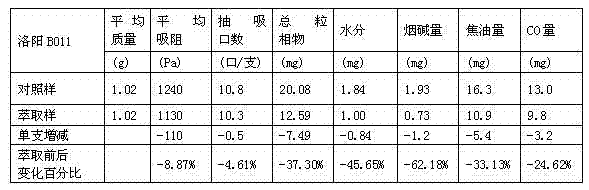

Embodiment 1

[0017] At a frequency of 2400MHz, after microwave treatment of 200kg Luoyang B011 cut tobacco for 2min, it was placed in a sealed pressure tank, and liquid CO was injected from the upper part of the pressure tank. 2 To fully soak the shredded tobacco, adjust the pressure to 2.8MPa, and then inject liquid CO from the upper part and draw out the lower part at the same flow rate 2, Realize flow extraction, the extraction time is 100s; the extracted liquid CO 2 Through decompression, it becomes a gaseous state and is separated from the extract, and then compressed into a liquid by a compressor for recycling. The separated extract can be used as a raw material or chemical raw material for making tobacco sheets by papermaking; The whole product is taken out from the tank, dried at a temperature of 100°C, and then blended into the cigarette formula in a certain proportion to achieve the purpose of reducing harm and tar.

Embodiment 2

[0019] At a frequency of 2500MHz, 200kg of Luoyang B011 shredded tobacco was microwaved for 5 minutes, then placed in a sealed pressure tank, and liquid CO was injected from the upper part of the pressure tank. 2 To fully soak the shredded tobacco, adjust the pressure to 3.0MPa, then inject liquid CO from the upper part and draw out the lower part at the same flow rate 2, Realize flow extraction, the extraction time is 400s; the extracted liquid CO 2 Through decompression, it becomes a gaseous state and is separated from the extract, and then compressed into a liquid by a compressor for recycling. The separated extract can be used as a raw material or chemical raw material for making tobacco sheets by papermaking; The whole product is taken out from the tank, dried at a temperature of 250°C, and then blended into the cigarette formula in a certain proportion to achieve the purpose of reducing harm and tar.

Embodiment 3

[0021] At a frequency of 2450MHz, 200kg of Luoyang B011 cut tobacco was microwaved for 4min, then placed in a sealed pressure tank, and liquid CO was injected from the upper part of the pressure tank. 2 To fully soak the shredded tobacco, adjust the pressure to 2.9MPa, and then simultaneously inject liquid CO from the upper part and draw out the lower part at the same flow rate 2, Realize flow extraction, the extraction time is 250s; the extracted liquid CO 2 Through decompression, it becomes a gaseous state and is separated from the extract, and then compressed into a liquid by a compressor for recycling. The separated extract can be used as a raw material or chemical raw material for making tobacco sheets by papermaking; The whole product is taken out from the tank, dried at a temperature of 150°C, and then blended into the cigarette formula in a certain proportion to achieve the purpose of reducing harm and tar.

[0022] Depend on figure 1 It can be seen that it is diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com