Mine automatic dedusting system and method

An automatic dust removal and mine technology, applied in the fields of dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of incomplete water dust removal and waste dust removal in mines, so as to avoid waste of water sources, and solve the waste of water and incomplete dust removal in mine dust removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

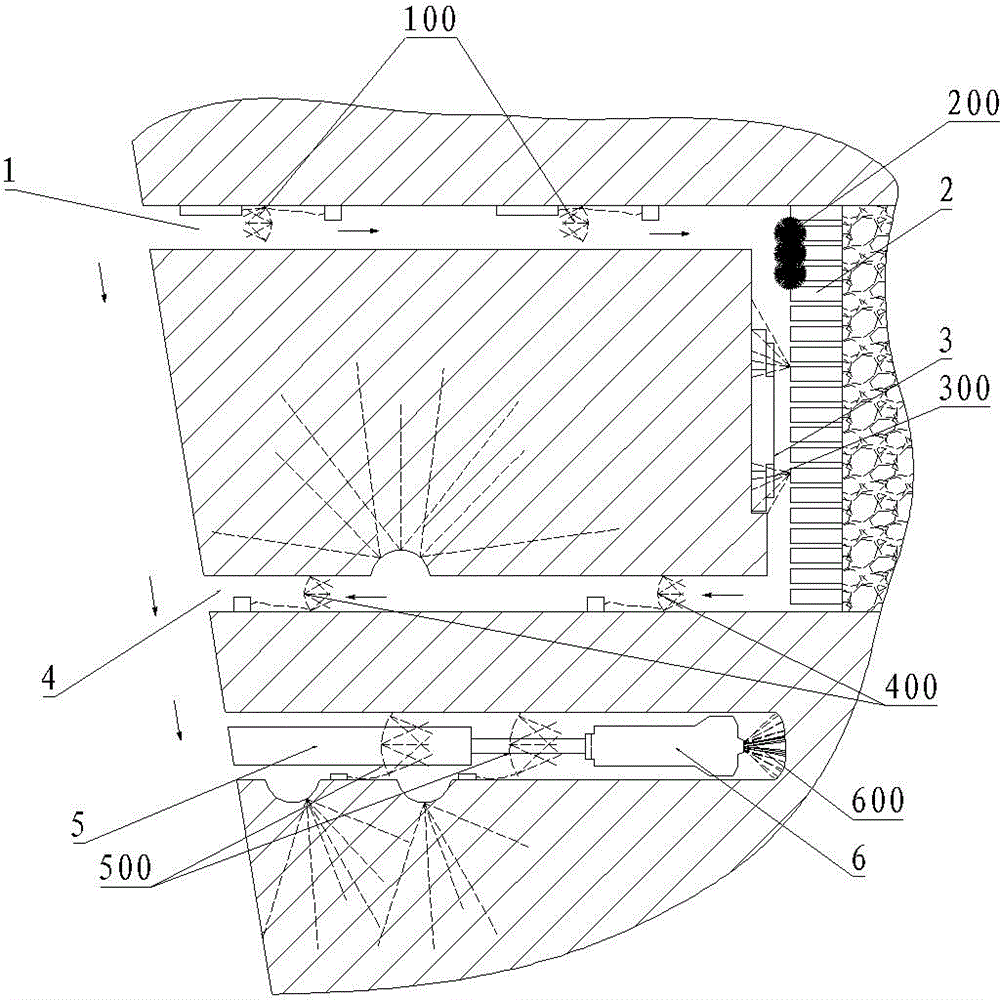

[0019] The embodiment of mine automatic dedusting method of the present invention: as figure 1 As shown, the following steps are included. In step 1, the air inlet dust removal unit 100 and the fully mechanized mining roadway dust removal unit 200 on the hydraulic support 2 are respectively arranged on the air inlet roadway 1, the fully mechanized mining roadway, the return air roadway 4 and the fully mechanized mining roadway. And the dust removal unit 300 of the fully mechanized mining face on the fully mechanized mining machine 3, the dust removal unit 400 of the return air, the dust removal unit 500 of the fully mechanized roadway on the belt conveying unit 5 and the dust removal unit 600 of the fully mechanized mining face on the fully mechanized mining machine 6, all The air inlet dust removal unit 100 and the return air dust removal unit 400 respectively have the first and fourth monitoring devices for detecting the entry and exit of the equipment train in the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com