Heat storage water tank

A hot water storage tank and heat storage cavity technology, applied in heat storage equipment, energy storage, heating devices, etc., can solve the problem of unreasonable shape design of heating liner or jacket, low heat conduction efficiency, and easy use of solar water heaters. Weather, day and night restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

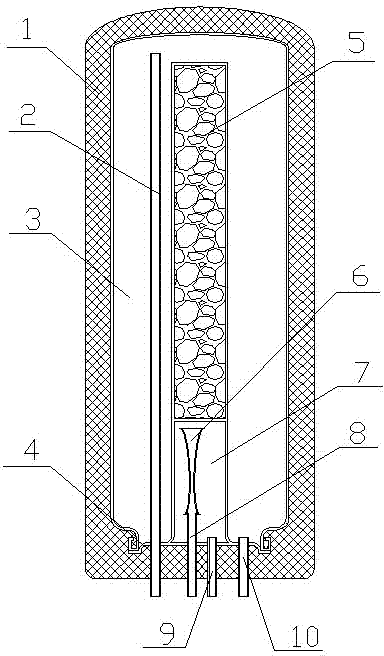

[0014] The hot water storage tank is connected with a flat solar heat collector, the heat storage chamber 5 is filled with phase change heat storage material, and the heating liner 7 is filled with a heat transfer medium with a low boiling point, and the heat transfer medium flows into the flat solar heat collector from the return pipe 9 The device absorbs heat. The heated and vaporized heat-conducting medium enters the heating inner tank 7 after being accelerated from the liquid inlet pipe 8 through the nozzle 6, hits the top of the heating inner tank 7, and liquefies with heat release. The water in the water storage chamber 3 absorbs heat from the heating liner 7 and heats up. The liquefied heat transfer medium flows back from the return pipe 9 to the flat solar heat collector. When the water temperature exceeds 50° C., the phase-change heat stor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com