A direct-acting proportional relief valve

A proportional relief valve, direct-acting technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of low cost, proportional increase in opening pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

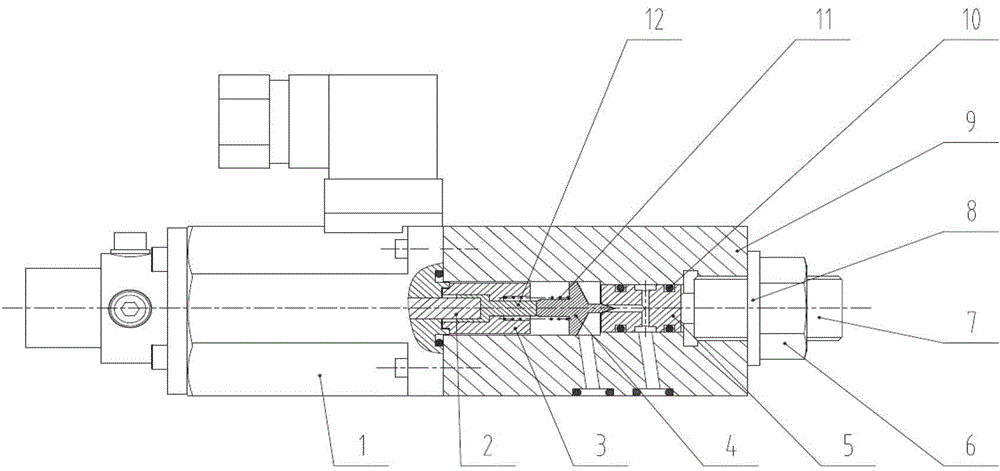

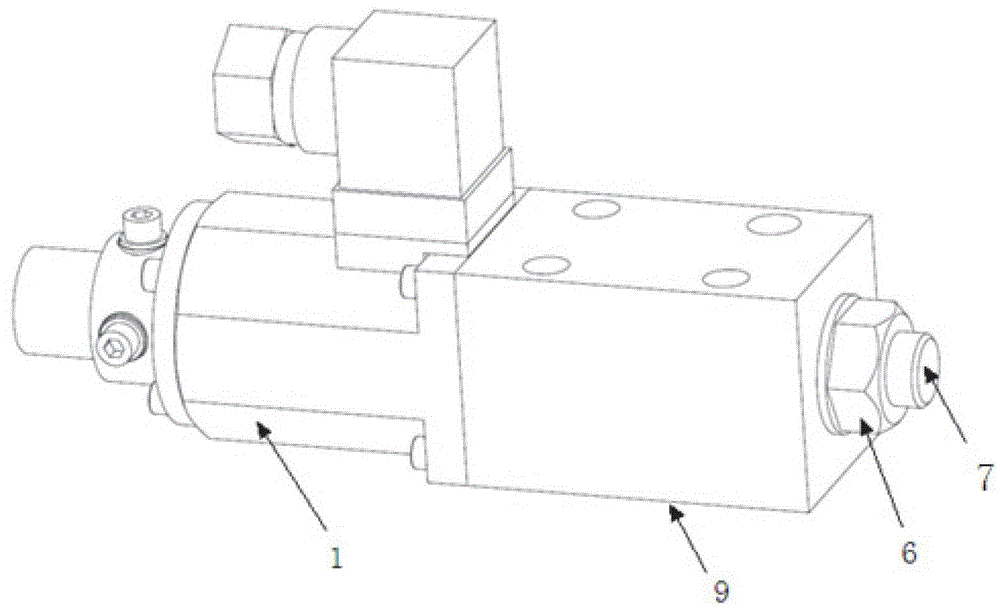

[0023] figure 1 It is the structural diagram of the direct-acting proportional overflow valve. It can be seen from the figure that the direct-acting proportional overflow valve consists of a proportional electromagnet 1, a spring seat 3, a transition rod 12, a spring 11, a spool 4, and a valve Seat 5, valve body 9 and adjusting screw 7 and other components. The spring seat 3, spring 11, valve core 4 and valve seat 5 are installed in the through hole of the valve body, the proportional electromagnet 1 is installed on the left end of the valve body 9, the spring seat 3 is directly installed on the right end of the proportional electromagnet 1, and the proportional solenoid The push rod 2 of iron penetrates in the seat hole of the spring seat 3, and is connected with the left end of the spool 5 by the transition rod 12. Spring 11 is installed on spring seat 3 and spool 4, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com