Rotary air curtain rang hood with oil fume filter device

A technology of oil fume filtration and range hood, which is applied in the field of kitchen utensils, can solve the problems of difficult cleaning, shorten the service life, and pollute the kitchen environment, and achieve the effects of high smoke collection efficiency, prevention of oil fume overflow, and high suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

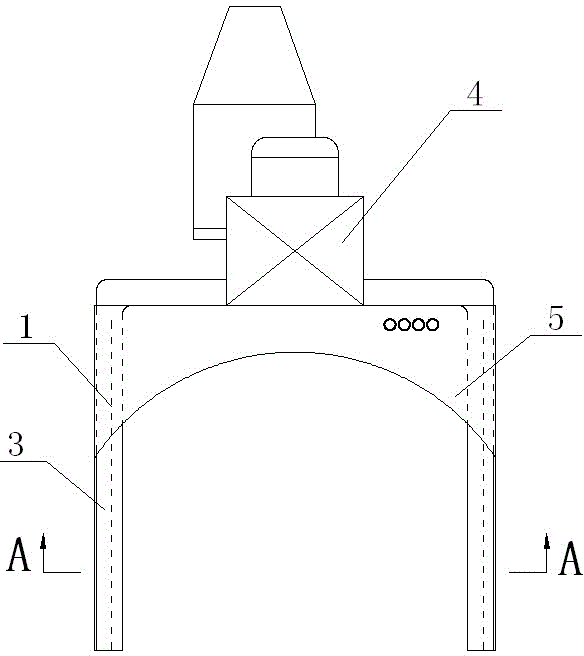

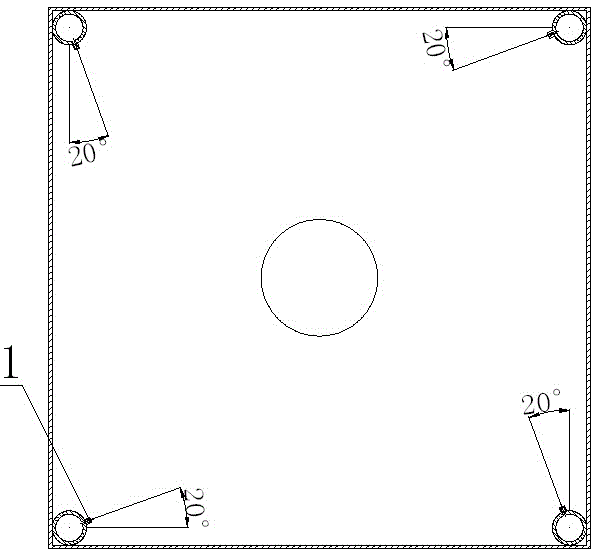

[0021] The range hood of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] see figure 1 , Figure 4 and Figure 5 As shown, the range hood of the present invention includes a hood 5, a blower fan 4, a bladeless fan 7, an air suction duct 9 and an oil fume separation device 6, the air suction duct 9 is in a substantially L-shaped structure, and one end of the air suction duct 9 is connected to the The oil fume separating device 6 is smoothly connected, and the other end is a bladeless fan 7 , and the hood 5 is located below the bladeless fan 7 . The suction duct 9 includes a first section connected to the oil fume separation device 6 and a second section connected to the first section and perpendicular to the first section.

[0023] The outlet of the fan 4 is provided with a first flow divider 10 for dividing the airflow in the fan 4 into two streams, so as to ensure that the two streams meet the required air flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com