Packing machine

A packaging machine and packaging technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of affecting packaging quality, difficulty in installation and debugging, and high technical requirements for design and manufacturing processes, and achieve the effect of simple and intuitive packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

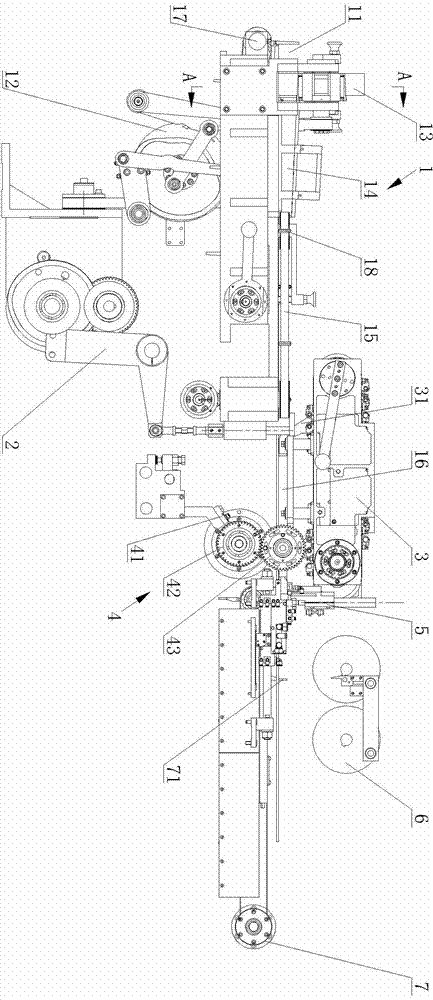

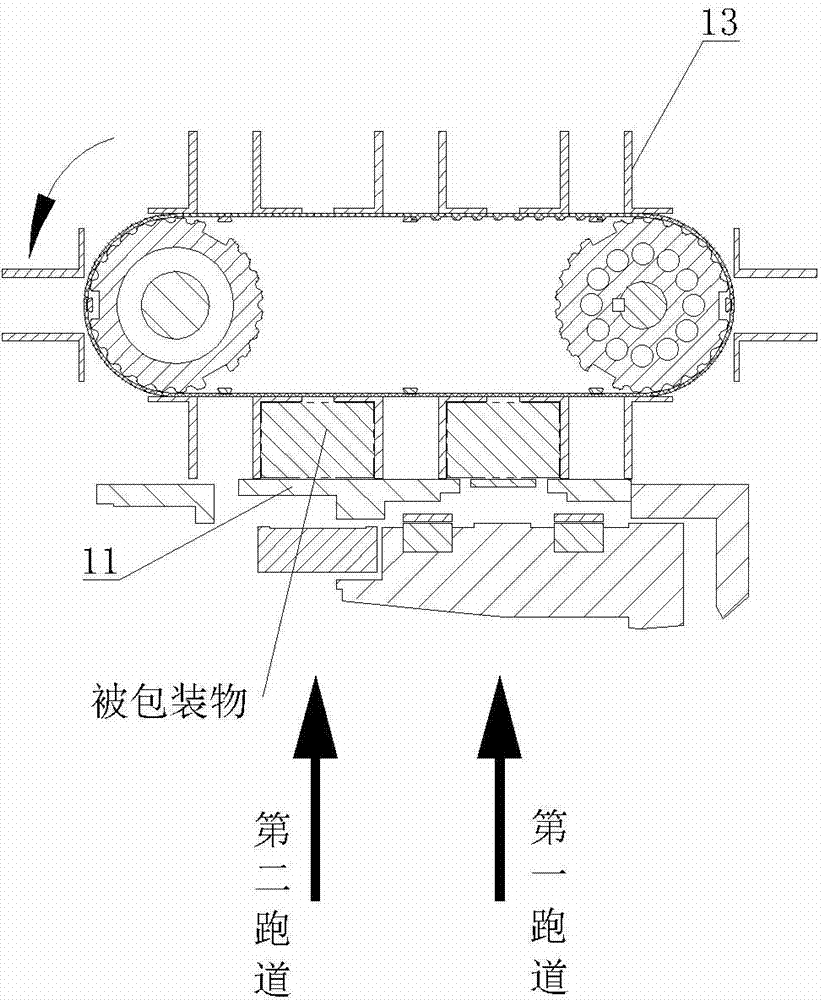

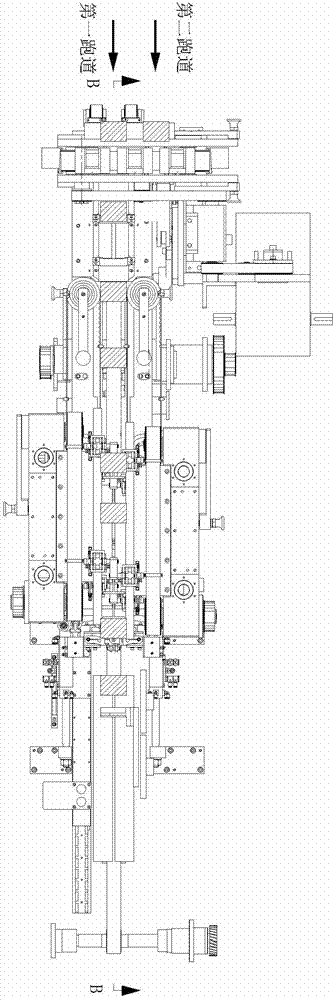

[0030] From Figure 1 to Figure 5 It can be seen that the packaging machine of the present invention includes a two-in-one conveying mechanism 1, a compression mechanism 2, a pushing mechanism 3, a package supply mechanism 4, a reciprocating mold box and a folding mechanism 5, a side sealing mechanism 6 and a pushing mechanism 7, Wherein the two-in-one conveying mechanism 1 includes an input channel 11, a runway pusher mechanism 12, a ferry mechanism 13 and a closed output channel, the input channel 11 is provided with a first runway and a second runway parallel to each other, and the output channel includes a horizontal pusher The rod mechanism 17, the belt conveying mechanism 18, and the primary compression channel 14, the transition channel 15 and the secondary compression channel 16 are connected in turn, the compression mechanism 2 includes a cam linkage mechanism and a slider mechanism, and the pushing mechanism 3 includes a synchronous belt and 4 pushers. Rake 31, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com