Continuous cable bundling mechanism

A technology of pulling handles and winding handles, which is applied to detonators, offensive equipment, etc., can solve the problems of difficulty in extracting detonators, low work efficiency, and inconvenient use by users, and achieve the effect of low work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

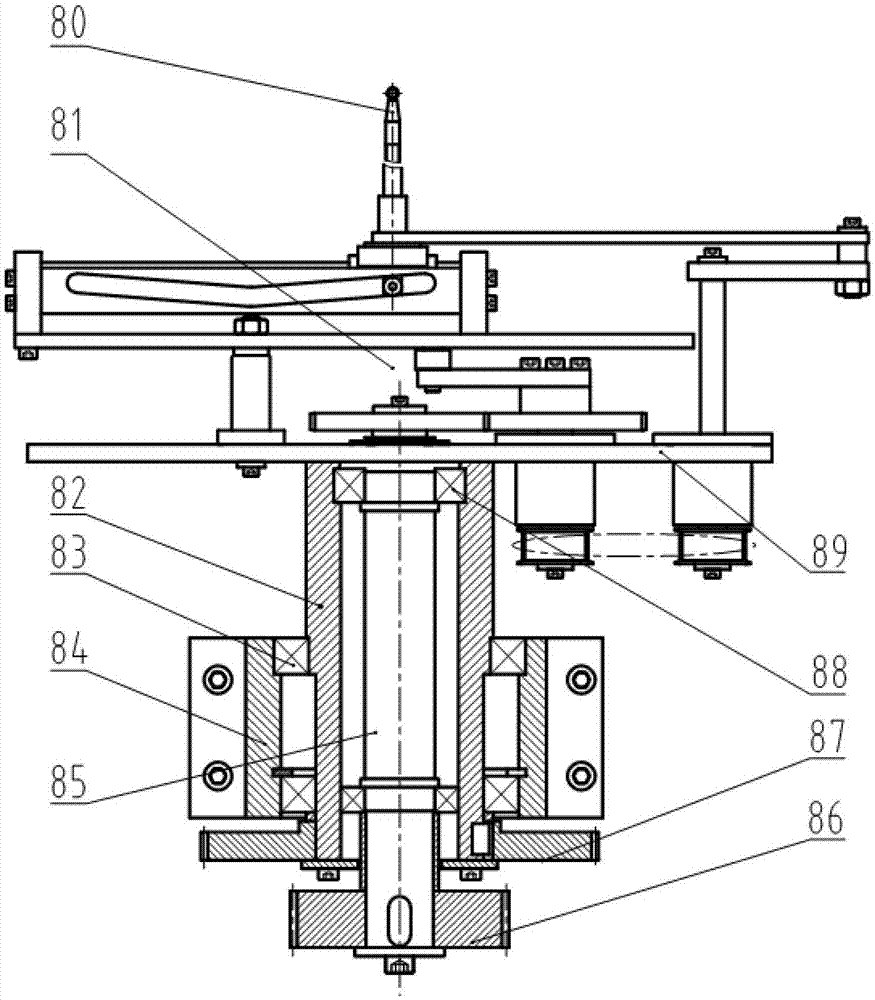

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

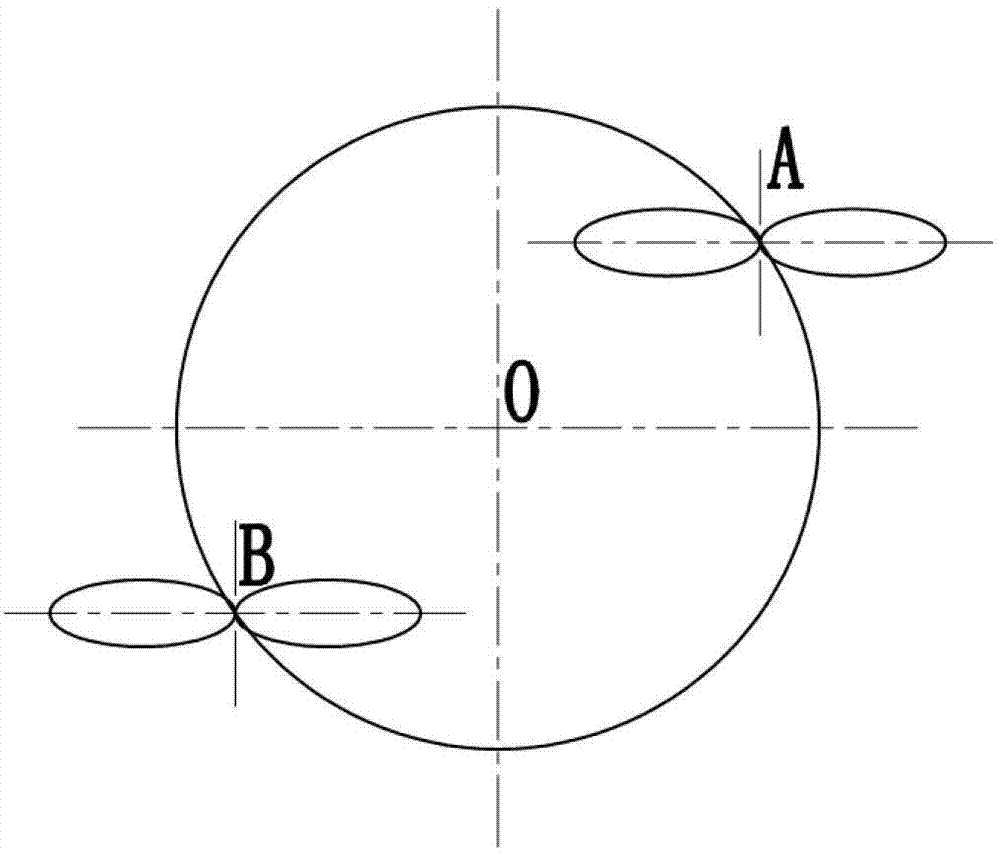

[0012] The present invention provides a continuous handle device with dual stations A and B, which improves the original process steps of handle-waist-cutting-stripping-discharging to complete the handle of the product at station A- At the same time as the tying process, station B completes the cutting-stripping-unloading process of the product at this station, and the handle head makes a circular motion from station A to station B to start the handle-waisting process of the product at this station, A The station completes the product cutting-stripping-unloading process of the station. These two stations go round and round to complete the continuous handle of the thread. This method makes a working cycle from handle-waist-cutting-stripping- The sum of the unloading time is reduced to the sum of the handle-waist time, which not only ensures the technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com