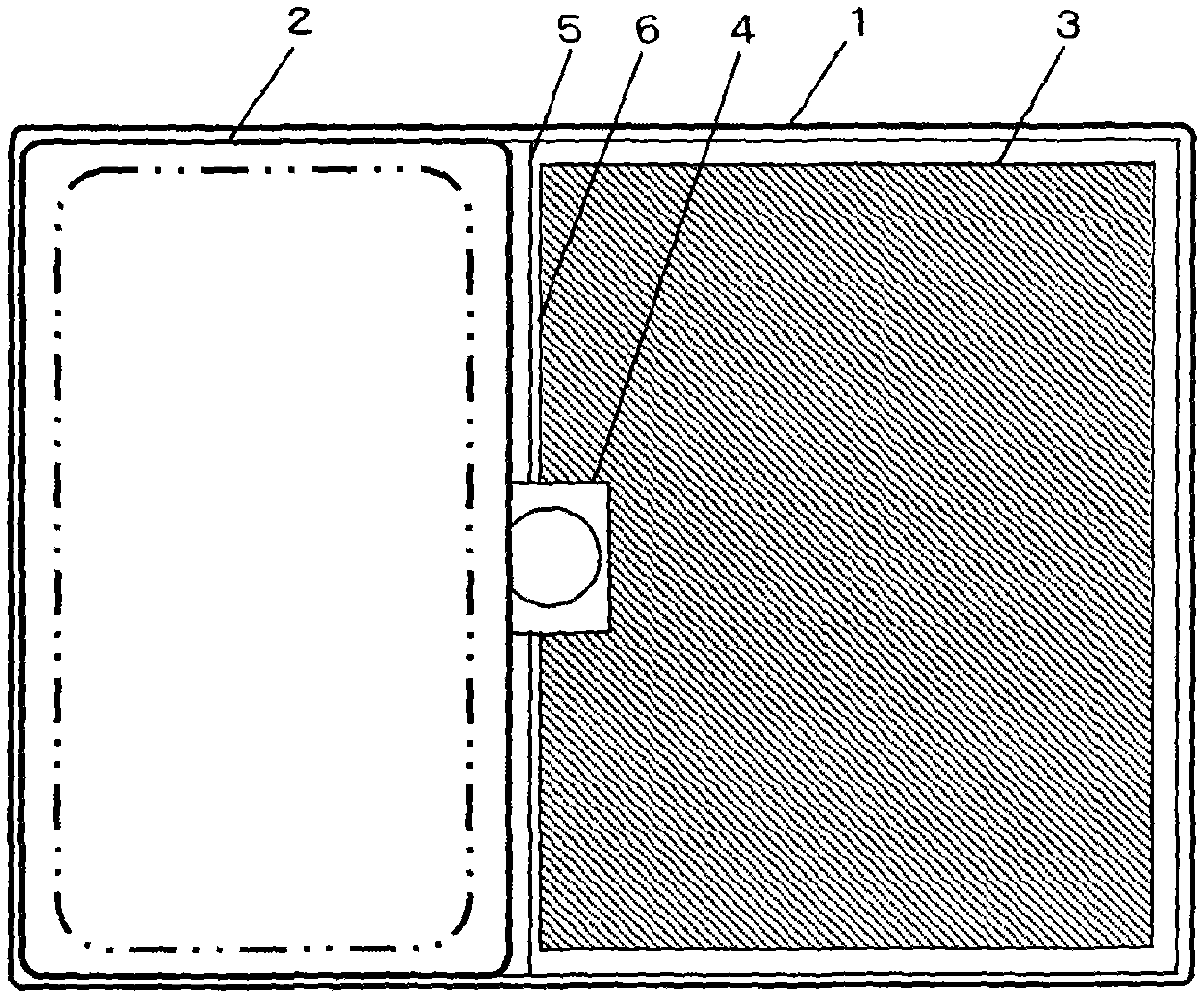

Bathroom floor components

A bathroom and floor technology, applied in drainage structures, building structures, waterway systems, etc., can solve the problems of loss of travel paths, difficult cleaning, easy pollution, etc., to maintain dry performance, improve easy cleaning, and reliable drying performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0061] A test panel having fine unevenness as a whole was produced. Adjust the fine unevenness so that when λc=0.08mm, Ra=1.454μm (Rz=6.573μm, Rt=15.267μm), when λc=0.8mm, Ra=7.307μm (Rz=35.511μm, Rt=48.783μm ).

[0062] Water was poured over the entire test panel using a shower to exhibit hydrophilicity, and the remaining water formed a thin water film. Regarding the drying performance, in method 1, all moisture is dried within about 4 hours. In Method 2, the hydrophilicity was not maintained due to the influence of the components of the conditioner, and the residual water formed water droplets, which did not dry for 4 hours. Regarding the anti-slip property, it was evaluated as "not easy to slip". Contamination recovery rate was 96%.

Embodiment approach 2

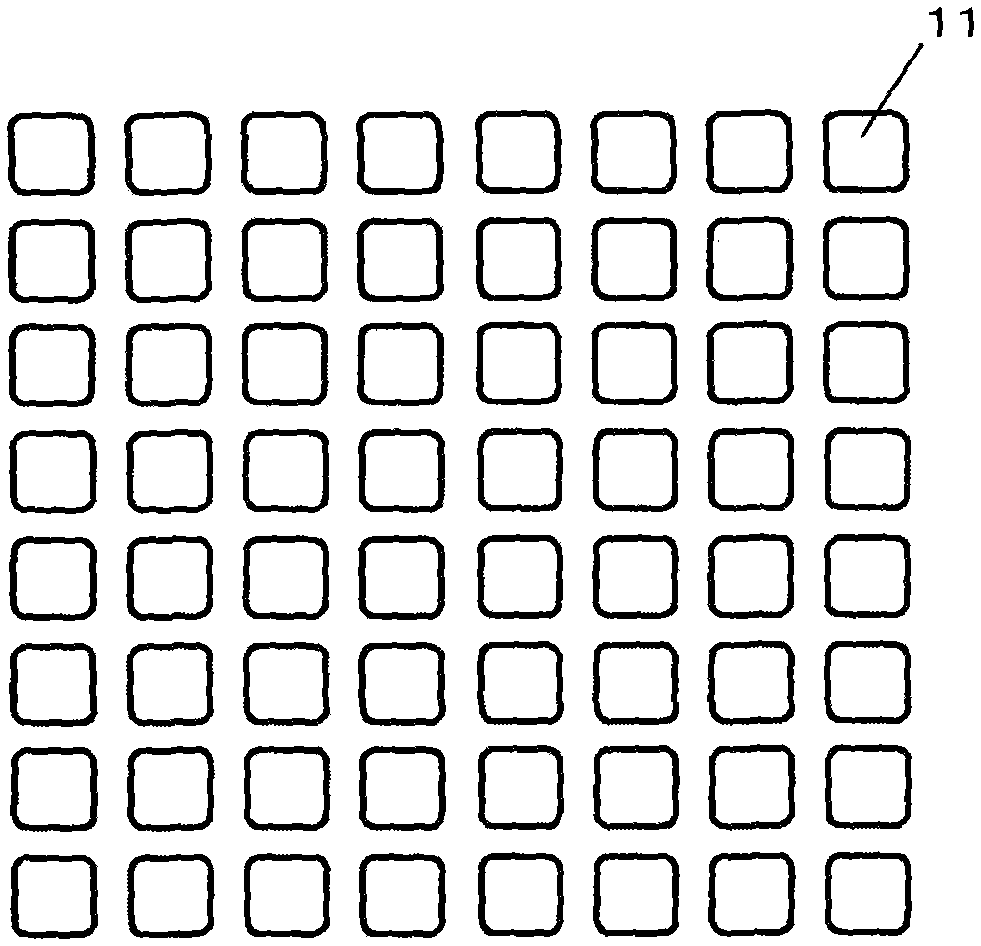

[0064] made as figure 2 Test panel with surface texture shown. Around the approximately 3 mm square concave portion 11, grid-shaped fine irregularities with a width of approximately 1.5 mm are provided. In addition, the concave portion 11 has a structure having the same height as the concave portion of the fine unevenness. That is, a structure positioned higher than the convex and concave portions of the fine unevenness. Adjust the fine unevenness so that when λc=0.08mm, Ra=0.822μm (Rz=3.665μm, Rt=10.938μm), when λc=0.8mm, Ra=7.644μm (Rz=33.724μm, Rt=51.104μm ).

[0065]Water was poured over the entire test panel using a shower to exhibit hydrophilicity, and the remaining water formed a thin water film. Regarding the drying performance, in method 1, all moisture is dried within about 4 hours. In Method 2, the hydrophilicity was not maintained due to the influence of the components of the conditioner, and the residual water formed water droplets, which did not dry for 4 h...

Embodiment approach 3

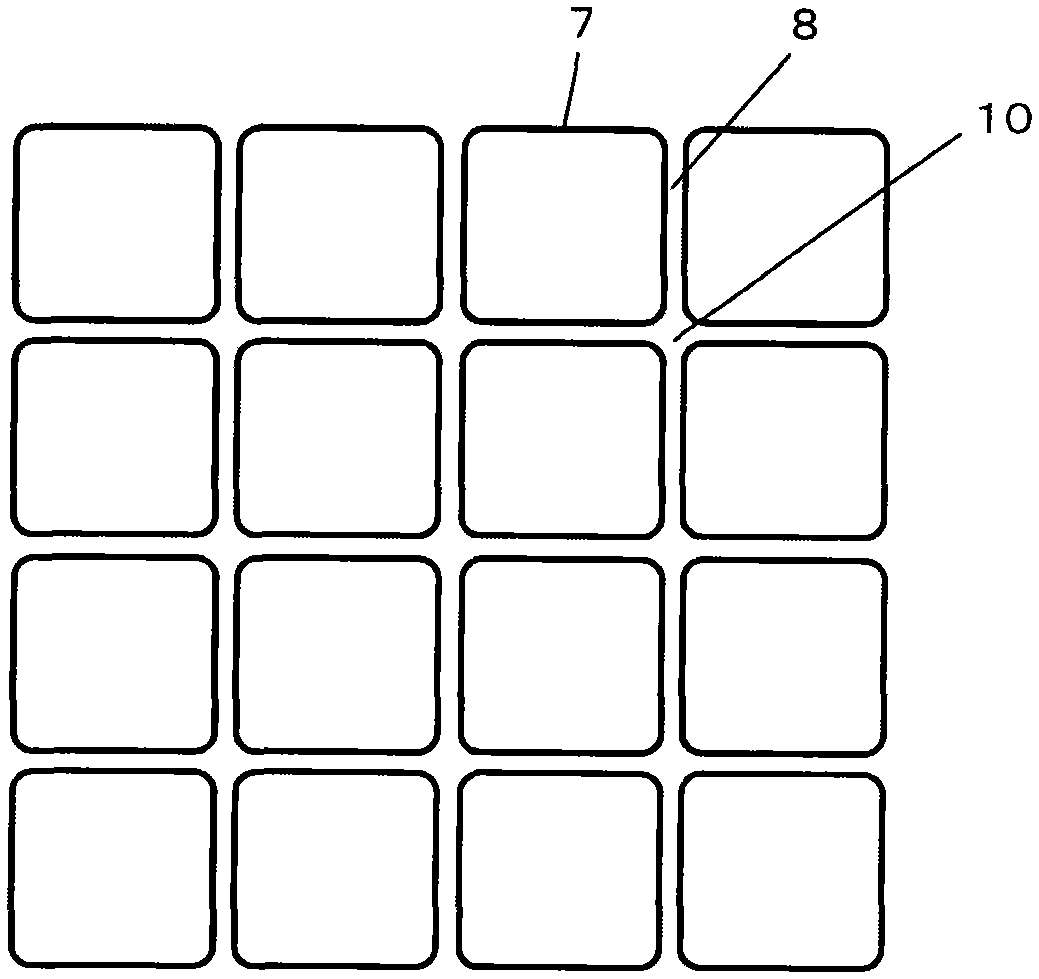

[0067] made as image 3 Test panel with surface texture shown. The convex part 7 is a square of about 12 mm, the depth of the groove part 8 is 0.4 mm, and the width is 0.4 mm. In addition, fine unevenness is implemented on the convex portion 7 and the groove portion 8, and the convex portion 7 is adjusted so that Ra=1.338 μm (Rz=6.411 μm, Rt=14.738 μm) when λc=0.08 mm, and Ra=1.338 μm when λc=0.8 mm. In mm, Ra=6.924 μm (Rz=35.389 μm, Rt=53.693 μm). Adjust the groove portion 8 so that Ra=1.411 μm (Rz=6.234 μm, Rt=14.163 μm) when λc=0.08 mm, Ra=4.886 μm (Rz=29.458 μm, Rt=39.017 μm) when λc=0.8 mm μm).

[0068] Water was poured over the entire test panel using a shower to exhibit hydrophilicity, and the remaining water formed a thin water film. Regarding the drying performance, in method 1, all moisture is dried within about 4 hours. In method 2, the hydrophilicity was not maintained due to the influence of the ingredients of the conditioner, but all the moisture was dried w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com