Pressure-proof watertight circular door for ships and warships

A pressure-resistant, ship-like technology, applied in the field of watertight doors, can solve problems such as poor sealing performance, watertight door structure, performance impact, and inability to ensure product pressure resistance, and achieve the effect of reducing safety hazards and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

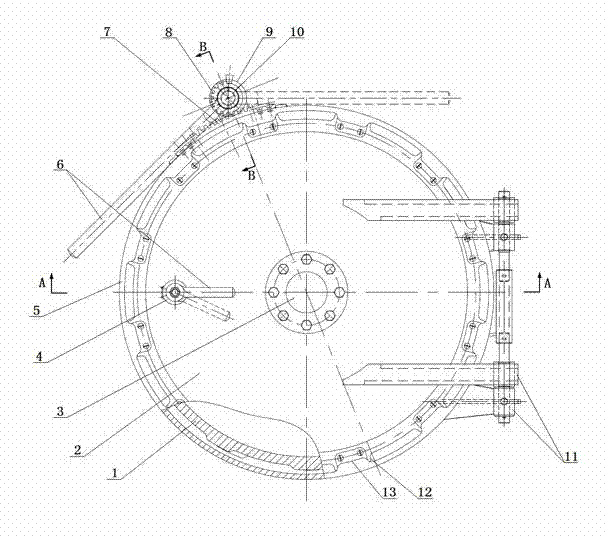

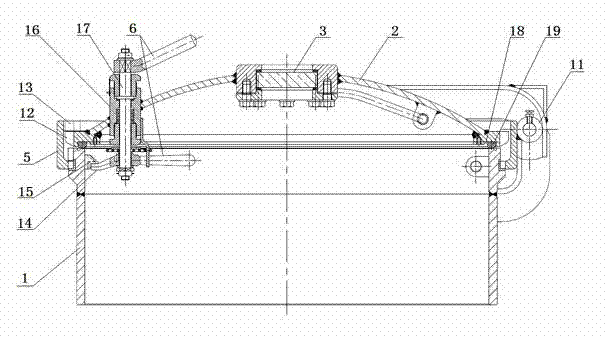

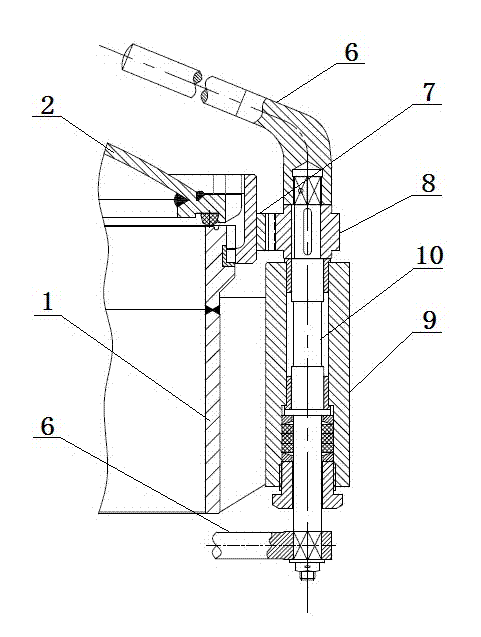

[0013] Such as Figure 1 to Figure 3 As shown, the pressure-resistant watertight round door for ships of the present invention comprises a door panel 2 and a short cylinder 1 used as a door frame. The door panel 2 is an outwardly protruding spherical panel with a through hole at its central position. There is a glass plate, and the glass plate and the through hole are sealed and fixedly connected to form a glass observation window 3 . One side of the door panel 2 and the short cylinder 1 is hinged together by a hinge 11, and there is a locking mechanism 4 between the door panel 2 and the short cylinder 1 on the opposite side of the hinge point. The locking mechanism 4 includes a second bushing 16, the second The shaft sleeve 16 is fixed on the door panel 2, and the second shaft sleeve 16 has a second rotating shaft 17, the two ends of the second rotating shaft 17 protrude outside the second shaft sleeve 16, and there is a handle on the extended end thereof 6. A deadbolt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com