Connector assembly for plug-in electrical connectors, plug-in electrical connectors and manufactured cables

A technology of plug-in connectors and connector components, which is applied to the parts of the connecting device, the device for relieving the stress at the connection of the wires, and the connection, etc. It can solve the problems of increasing components, costs and assembly costs, and achieves simplicity and cheapness. Assembled, compact and robust design, long-running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

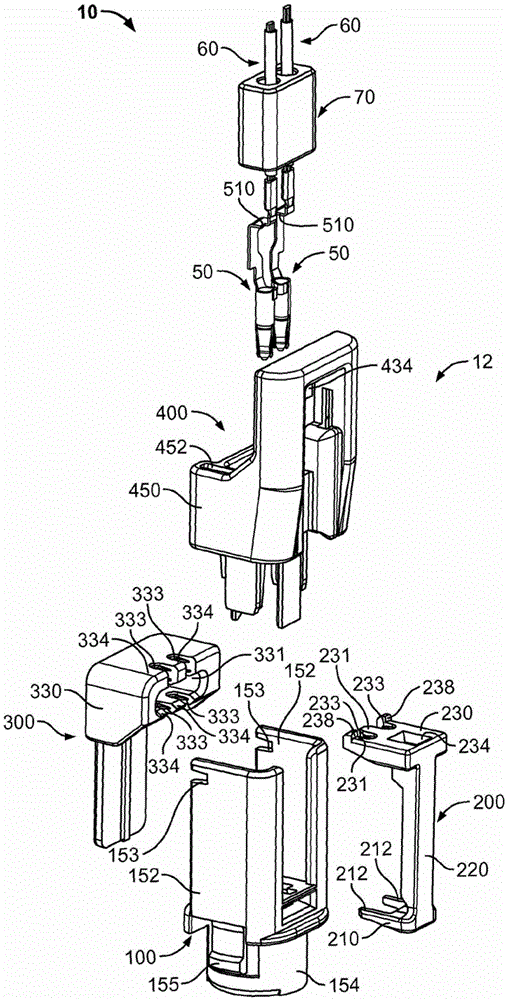

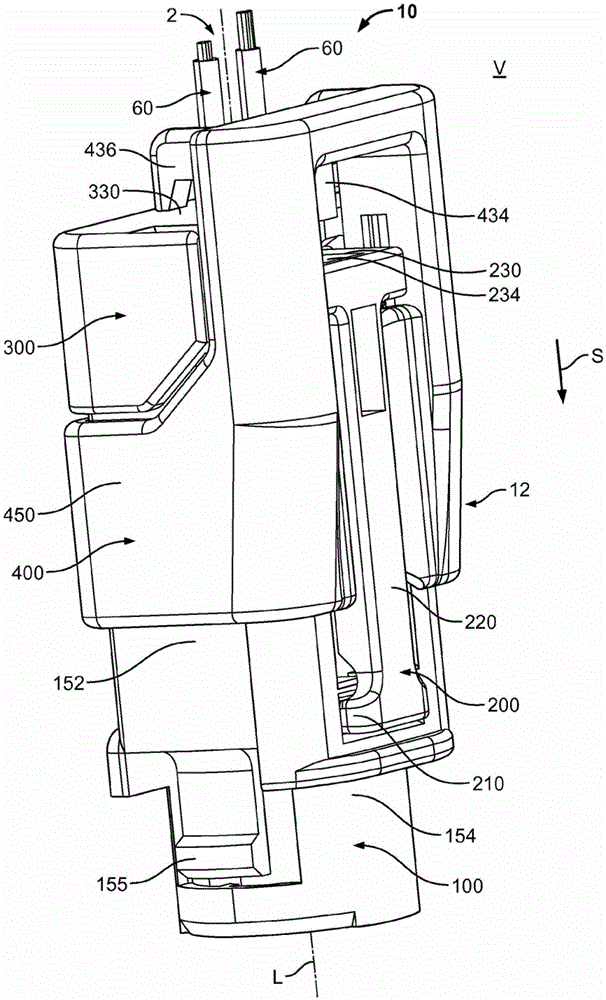

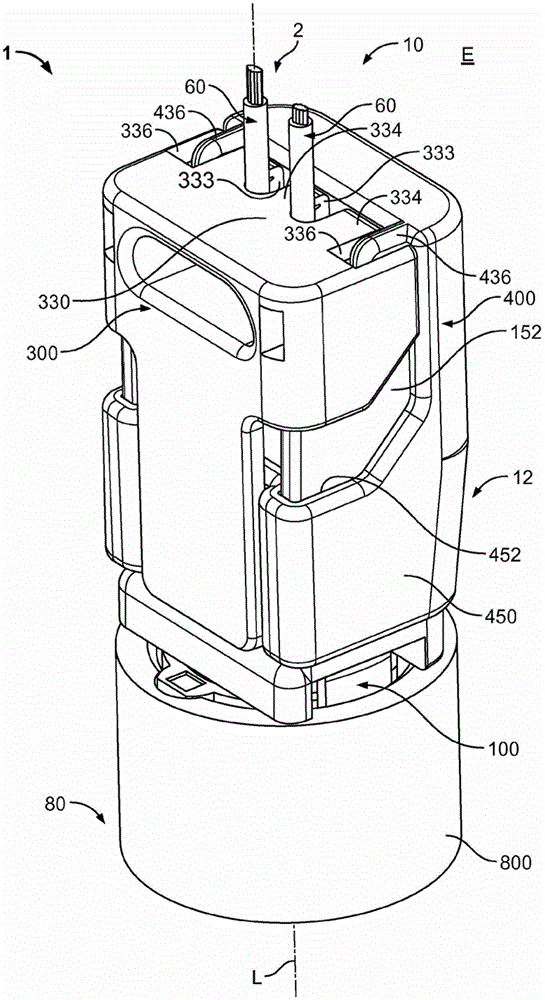

[0028] The invention will be described in more detail below with reference to a 180 degree socket plug-in electrical connector for electrical plug-in connection of airbags in the automotive industry. However, the invention is not restricted to this form of application, but can also be used in other fields of electrical engineering, in particular in safety-critical applications. Of course, the invention is also applicable to male or plug-in electrical connectors. Two specific embodiments of the invention are shown in greater detail below, each of which includes a number of the above variants of the invention. Of course, single or multiple variants described above can also be implemented in an embodiment of the present invention.

[0029] If further reference is made below to blocking, latching, locking or engaging, then these terms may be used sensibly. That is, means pertaining to blocking or latching can also be applied to locking or engaging, and vice versa. That is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com