Low-frequency-stage magnetic sensor background noise measuring method

A magnetic sensor and background noise technology, applied in the direction of noise figure or signal-to-noise ratio measurement, can solve the problems of poor accuracy of background noise, inability to accurately judge the performance of magnetic sensors, etc., and achieve the effect of accurate reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A method for measuring the background noise of a low-frequency band magnetic sensor, comprising the following steps:

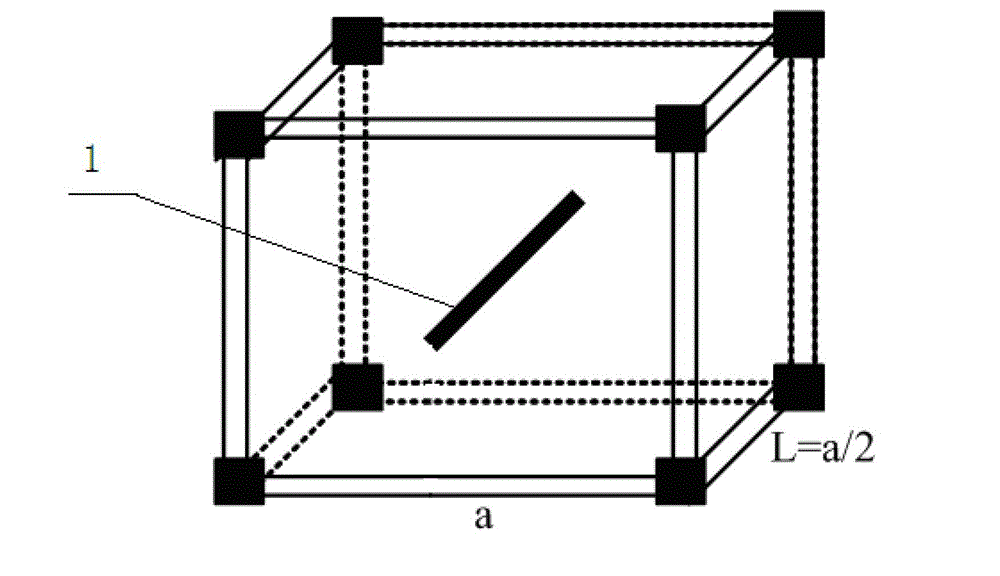

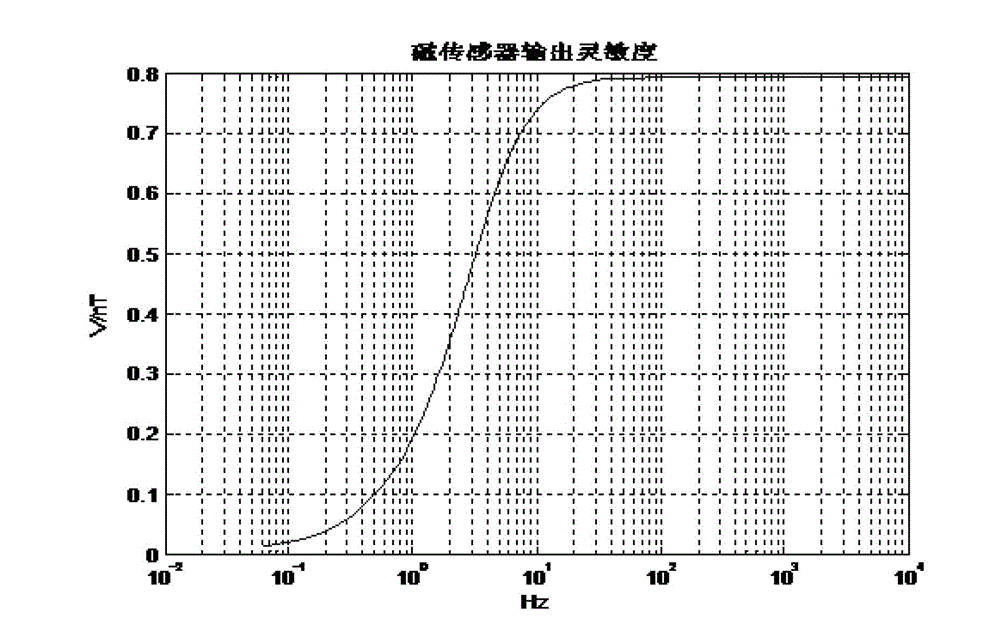

[0035] Consistency adjustment step: place the No. 1 magnetic sensor in the uniform magnetic field generating device, and sequentially input frequency sweep signals with fixed strength, different frequencies and the same phase to the uniform magnetic field generating device, and adjust the amplitude-frequency response curve of the magnetic sensor so that It is consistent with the design target curve; the No. 2 magnetic sensor is placed in the uniform magnetic field generating device, and the amplitude-frequency response of the magnetic sensor is adjusted by sequentially inputting frequency sweep signals with fixed strength, different frequencies and the same phase to the uniform magnetic field generating device Curve to make it consistent with the design target curve;

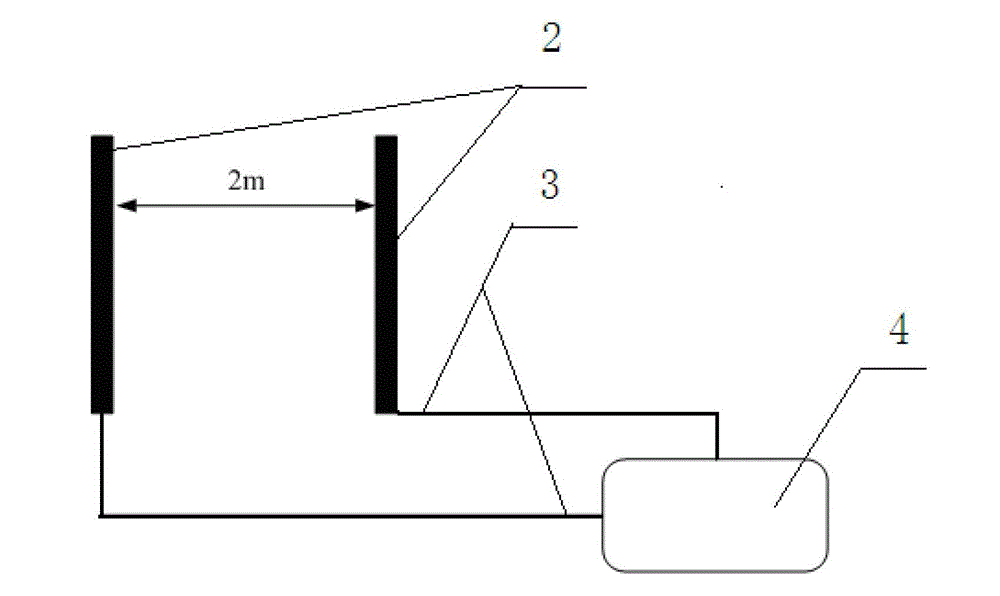

[0036] The noise floor differential measurement step: Place the No. 1 and No. 2 magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com