Intelligent material distribution control method and intelligent material distribution system for oil press

A control method and oil press technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as inability to intelligently control material flow, different difficult and easy procedures, etc., to achieve the effect of ensuring oil extraction performance, processing performance, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

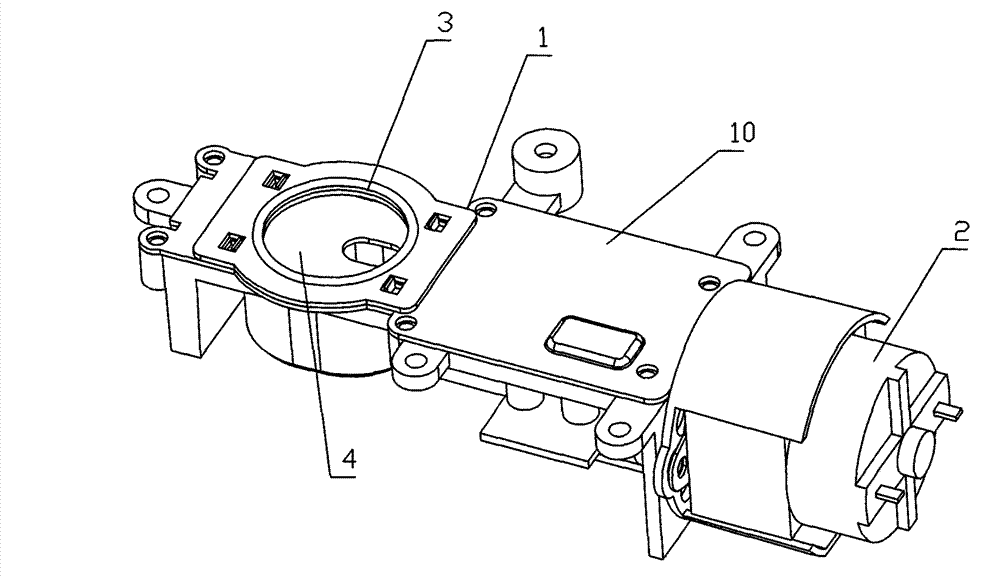

[0034] Embodiment 1: as Figure 1 to Figure 6 As shown, the intelligent material distribution system of the oil press includes a body, an oil extraction motor, a current detector for detecting the load current of the oil extraction motor, and a material distribution device. The body includes a pressing chamber and a loading container. The squeezing cavity is provided with a material port for entering materials, and the material loading container communicates with the material port through the material port of the material distribution device.

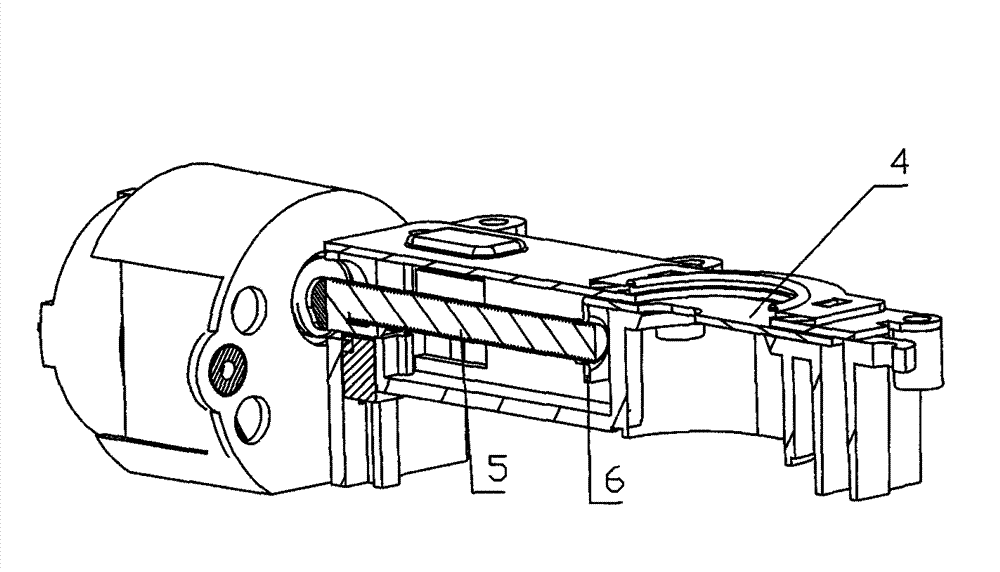

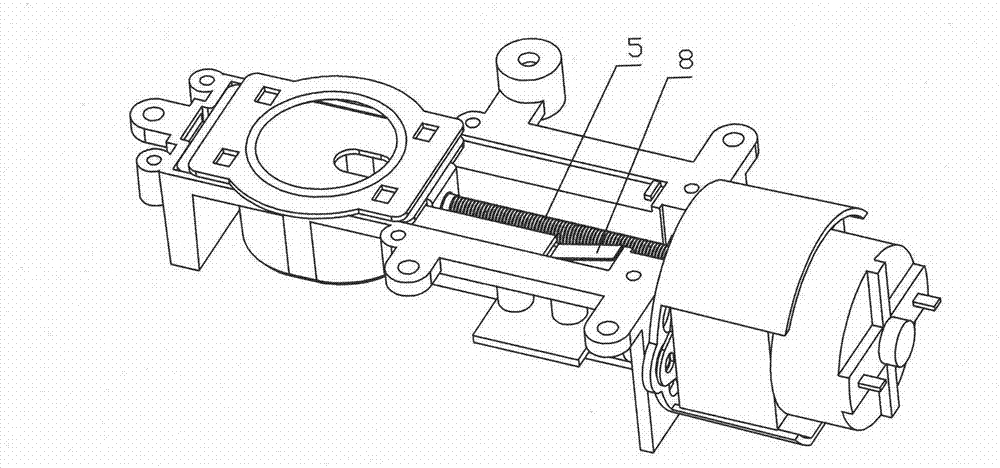

[0035] The material distribution device includes a main body 1, a cover body 10, and a motor 2 that provides power to the transmission mechanism. The main body 1 is provided with a material opening 3, and the material opening 3 is provided with a movable flow stopper 4 that can block the material opening 3. The transmission mechanism includes a screw rod 5 for dragging the flow stopper 4 and a threaded hole 6 arranged on the flow stoppe...

Embodiment 2

[0039] Embodiment 2: The characteristic of this embodiment is that the number of turns switch is an infrared switch. The number of turns control structure is provided at the side wall of the screw rod, protrudes outwards, turns to the turn number switch to block the infrared ray of the turn number switch. The working principle of this example is the same as that of Example 1.

Embodiment 3

[0040] Embodiment 3: The characteristic of this embodiment is that the turn switch is a magnetic switch. The turn control structure is a magnet arranged at the side wall of the screw rod and turned to the turn switch to close the turn switch. The working principle of this example is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com