High-speed dispersion machine with rotating device

A high-speed disperser and rotating device technology, which is applied to mixers with rotating containers, mixers, mixer accessories, etc., can solve the problems of different mixing states, different mixing times, easy differences, and metal powders, etc. Stirring and dispersing effect, better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

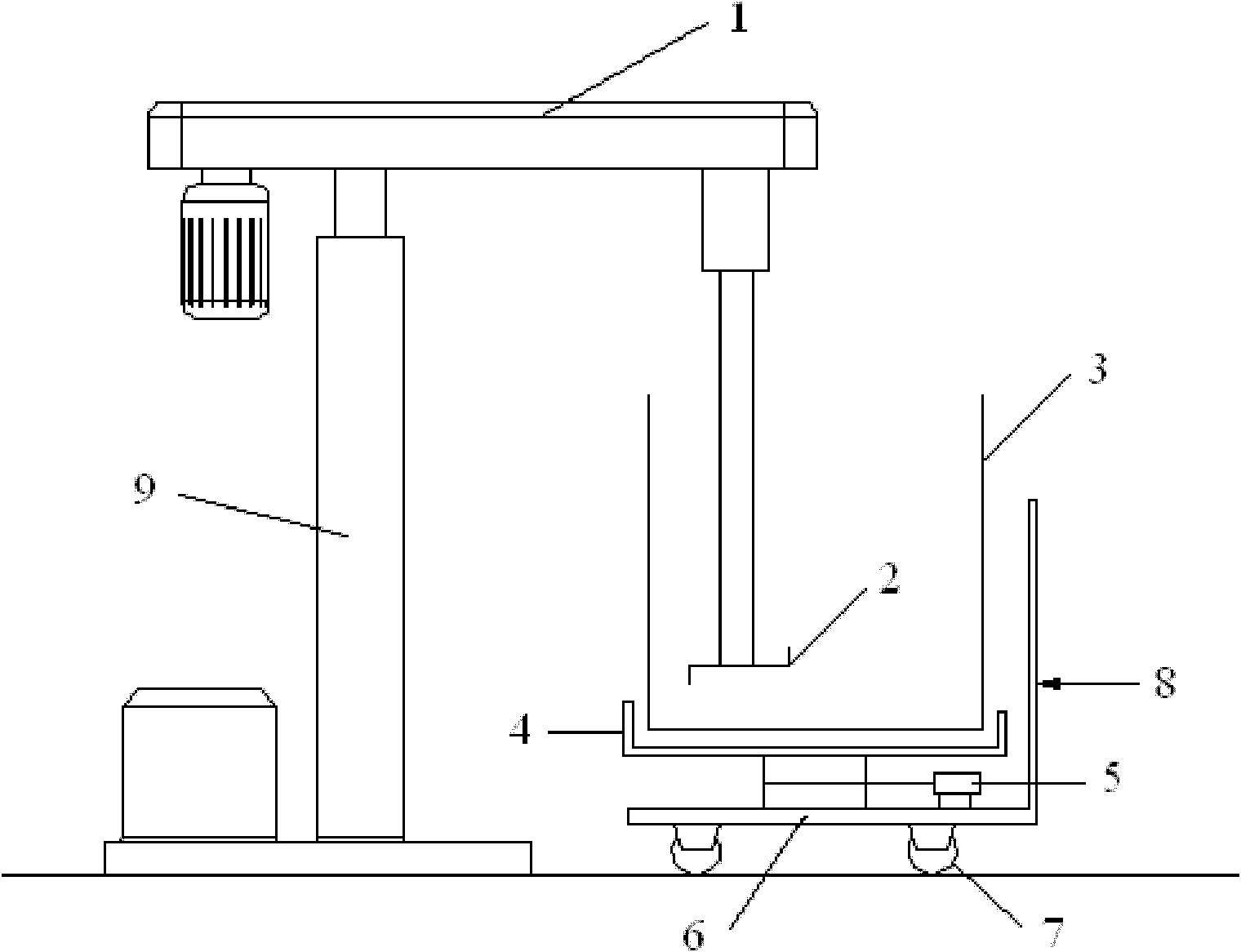

[0013] An embodiment of a high-speed disperser with a rotating device of the present invention will be described in detail below with reference to the accompanying drawings.

[0014] A high-speed dispersing machine with a rotating device of the present invention includes a lifting column 9 and a beam 1, a bearing column is vertically arranged on the beam, and a stirring plate connected with a stirrer 2 is positioned at one end of the bearing column facing away from the beam. shaft, and the stirring shaft can move up and down with the up and down operation of the lifting column; the stirring plate can rotate around its axis and be positioned in the stirring and dispersing container 3, and the stirring and dispersing container can rotate around its center, And the center of the stirring and dispersing vessel deviates from the axis of the stirring plate, that is, the axis of the stirring plate and the center of the stirring and dispersing vessel are not on the same axis, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com