Dispersion machine with material scraping and uniform stirring functions

A disperser and functional technology, applied in mixers with rotary stirring devices, mixer accessories, mixers, etc., can solve the problems of inability to be further stirred and dispersed, poor stirring and dispersing effect of the disperser, and adhesion of slurry raw materials, etc. Achieve the effect of improving stirring and dispersing effect, absorbing vibration and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

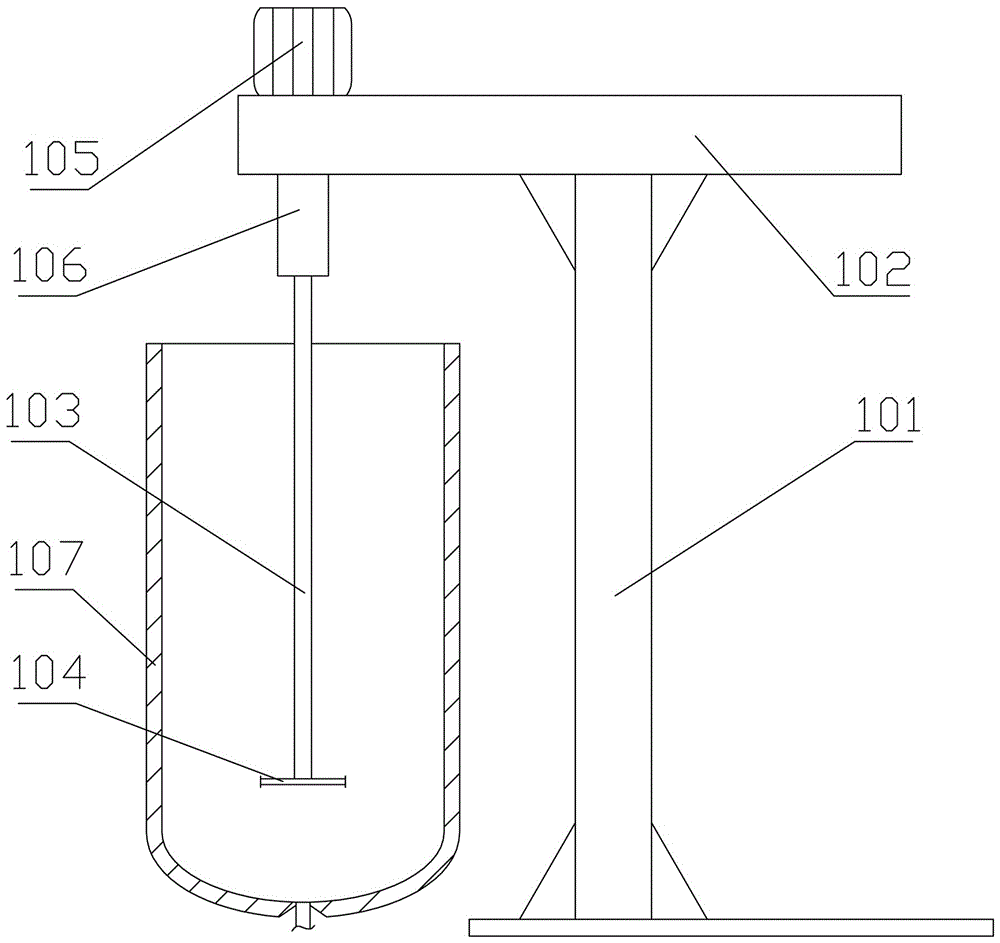

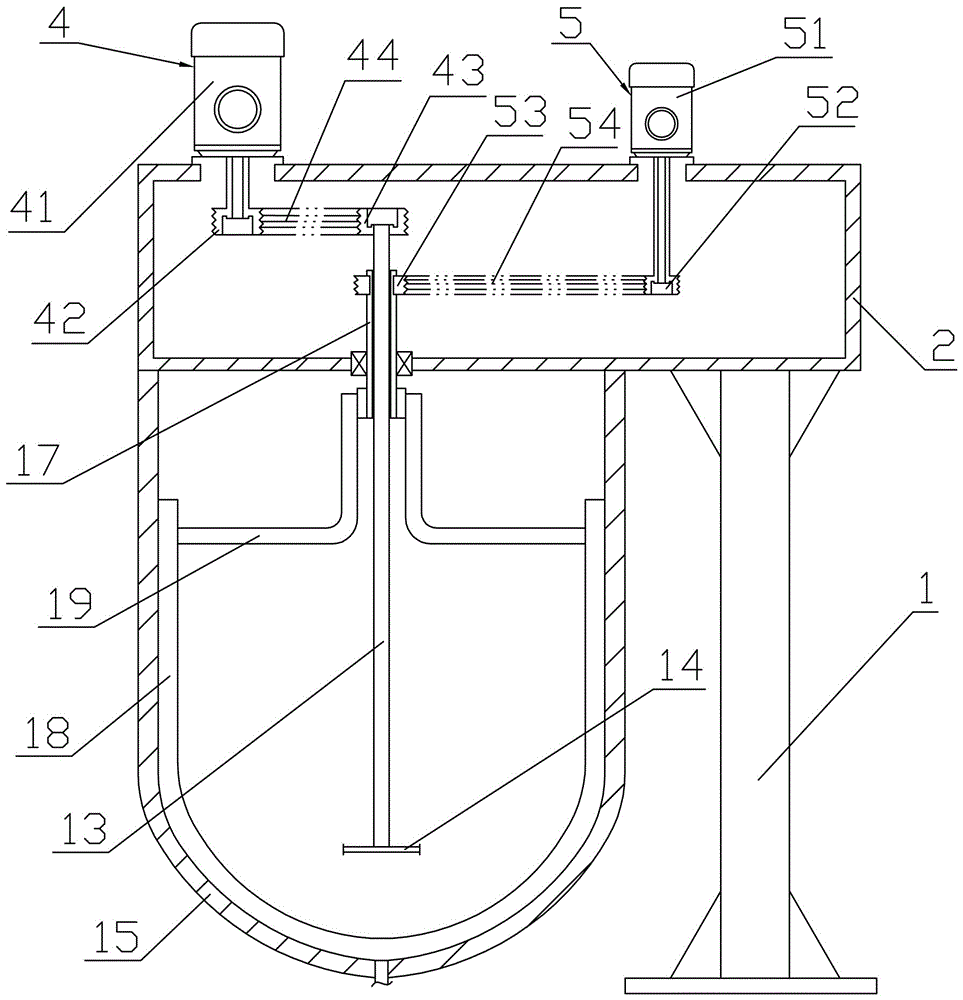

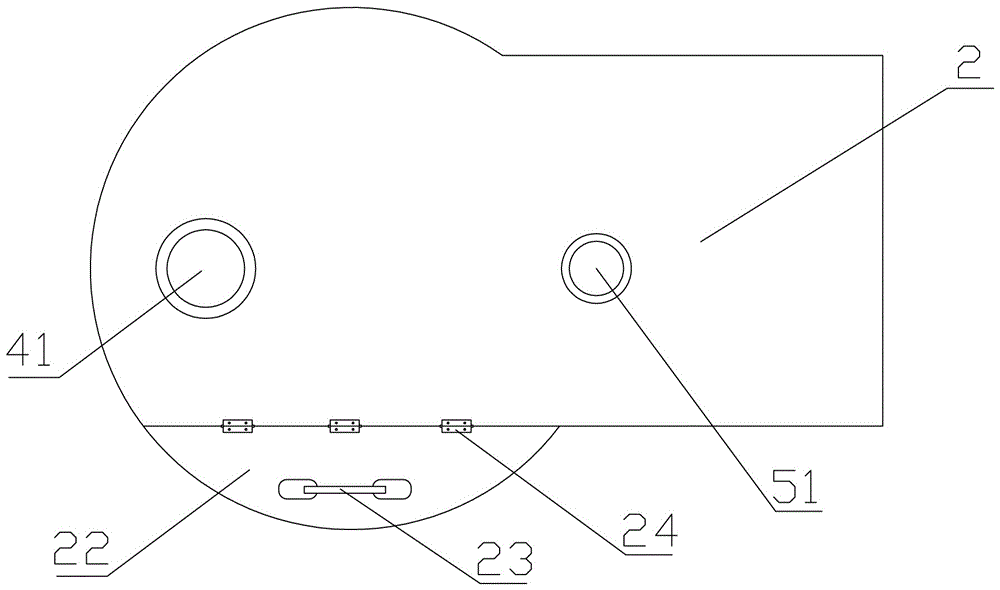

[0016] Such as figure 2 As shown, the dispersing machine with the function of scraping and stirring includes: a frame 1, a horizontally protruding suspension beam frame 2 is arranged on the frame 1, and a main shaft 13 is movably supported in the suspension beam support 2, and the lower end of the main shaft 13 is vertically The suspension beam frame 2 protrudes from the bottom, the lower end of the main shaft 13 is fixedly covered with a dispersing disc 14, and the suspension beam frame 2 is provided with a main driving device 4 for driving the rotation of the main shaft 13. In this embodiment, the specific structure of the main drive device 4 includes: a main drive motor 41 is arranged on the suspension beam frame 2, a drive wheel 42 is fixedly sleeved on the output shaft of the main drive motor 41, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com