Motor vehicle with crashbox

A collision energy absorption, automobile technology, applied to vehicle components, elastic shock absorbers, bumpers, etc., can solve problems such as changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

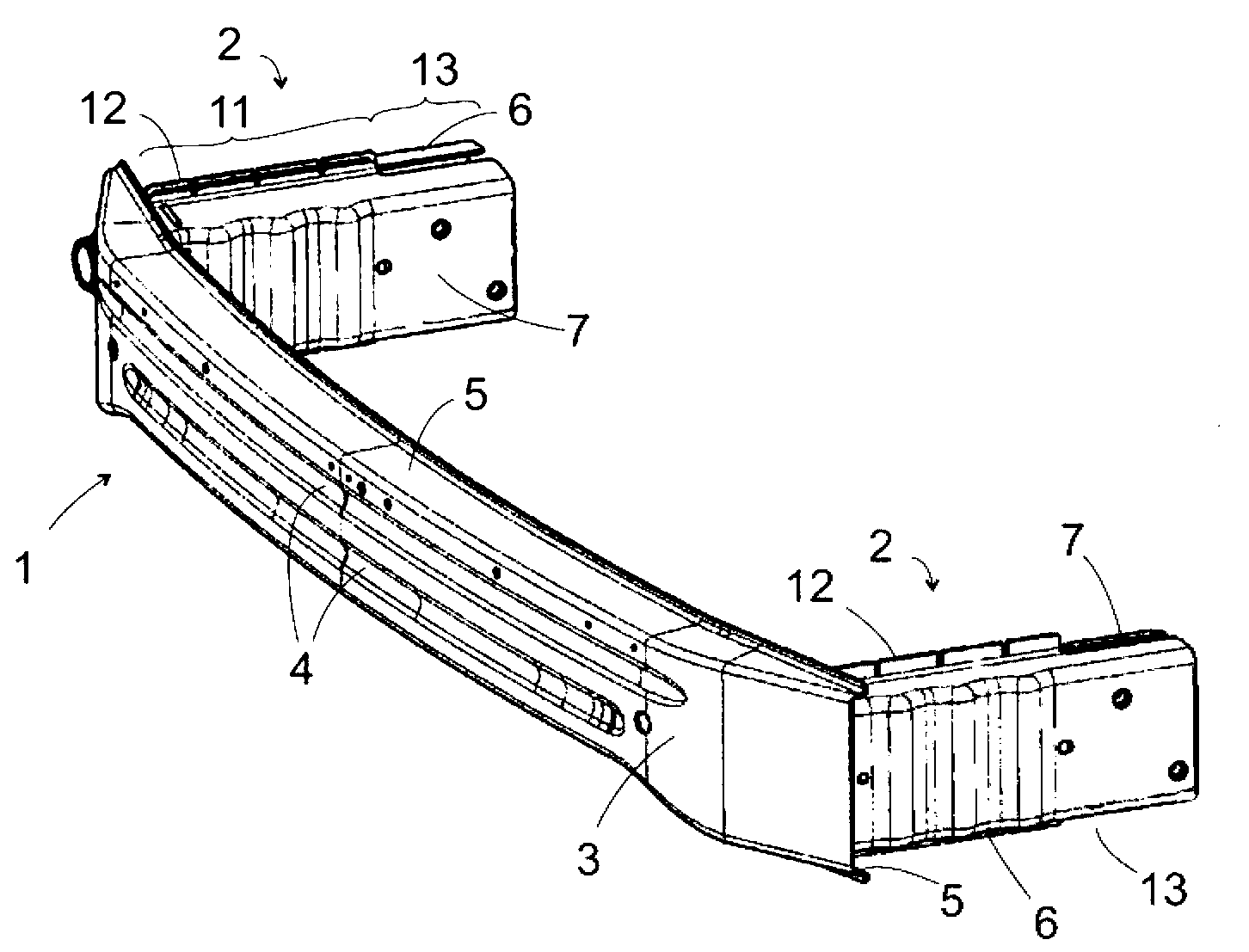

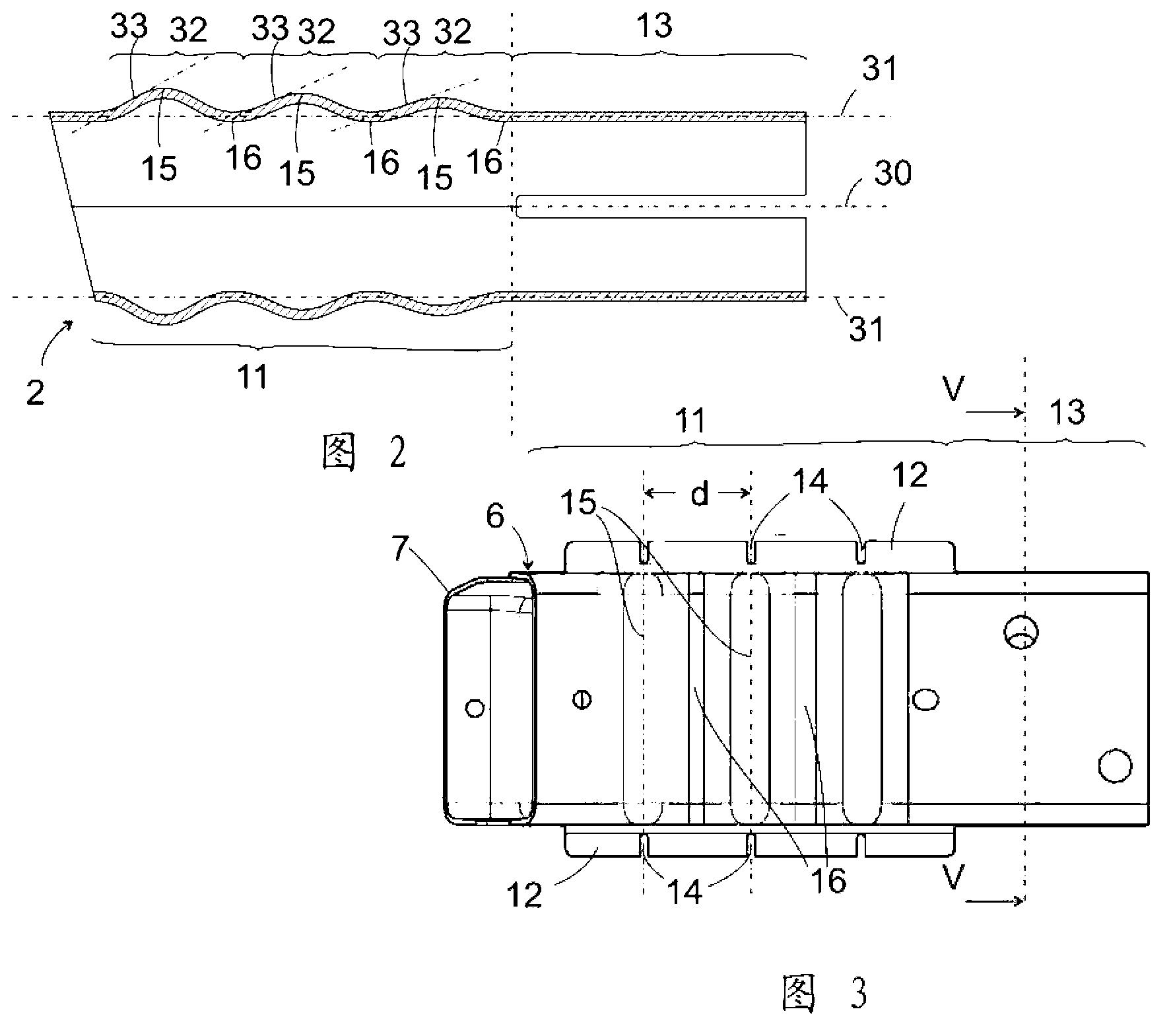

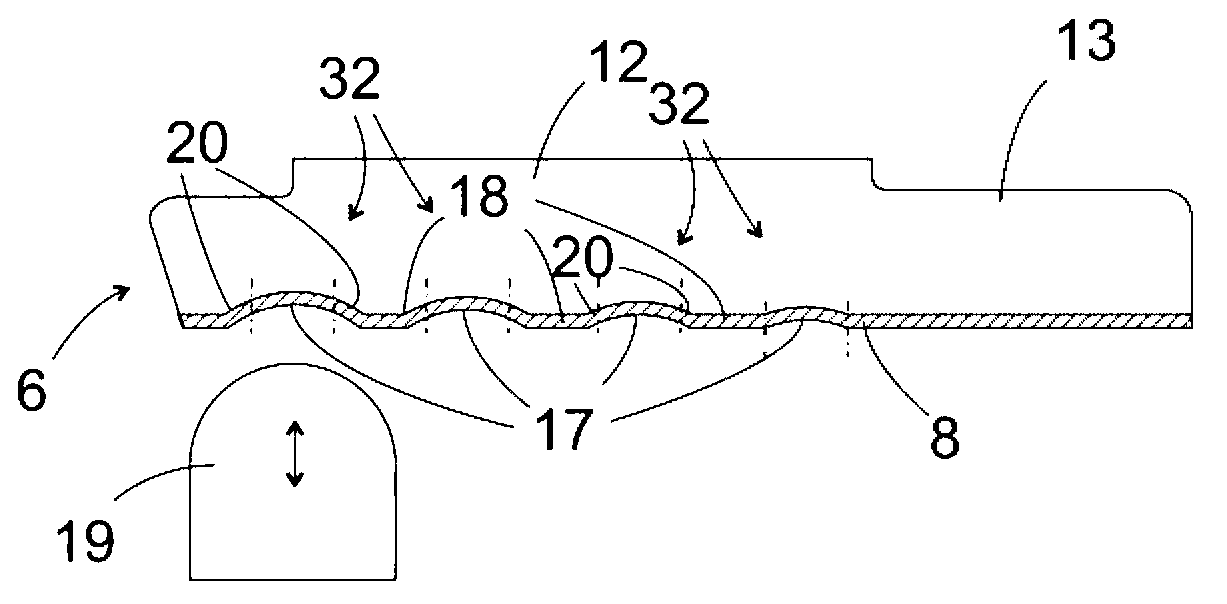

[0022] figure 1 A perspective view of the outside of a bumper 1 of a motor vehicle, in particular a passenger car, with two crash boxes 2 fastened to its rear side is shown. The bumper 1 is here a simple single-walled steel profile with an essentially C-shaped cross-section, which has two recesses punched in the transverse direction of the vehicle between the crash boxes 2 4 Reinforced panel 3 and side panels 5 bent horizontally from the upper and lower edges of panel 3 to the vehicle interior. The crash box 2 is joined to the rear side of the bumper 1 from the inside of the vehicle toward the cavity surrounded by the panel 3 and the side panel 5 and welded at this joint.

[0023] The crash boxes 2 each comprise two substantially channel-shaped parts here, which, for example, the bumper 1, are formed from steel plates and, in the channel-shaped parts, are arranged facing the The gutter-like part on the outside of the car is referenced 6 and the gutter-like part facing the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com