Motor stator structure

A motor stator and stator slot technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve problems such as winding shedding, unstable motor operation, and poor stability of square structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

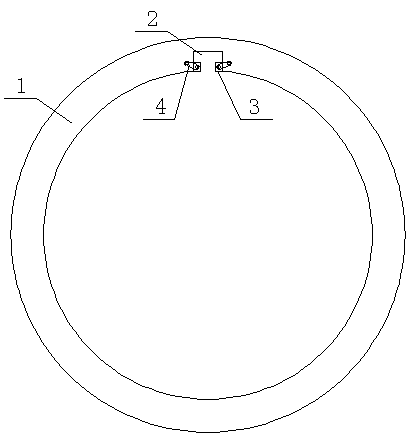

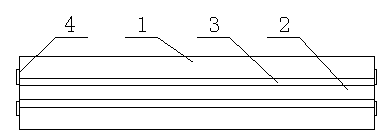

[0011] Such as Figure 1-2 As shown, the stator structure of the motor according to the embodiment of the present invention includes a stator housing 1, which is integrally formed, and a number of uniformly arranged stator slots 2 are arranged on the inner side of the stator housing 1. Beads 3 are respectively installed on the sides, so that the space for the stator slot 2 to accommodate the windings forms a "convex" shape. The stator slot 2 is arranged obliquely, that is, it is installed in a cable-stayed structure.

[0012] The stator housing 1 is circular.

[0013] The motor stator structure solves the problem of winding slippage, and can make the winding stability of the motor better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com