Apparatus and method for forming large-size winding composite material ring

A technology for winding composite materials and winding forming is applied in the field of forming devices for large-size winding composite material rings, which can solve the problems of being unsuitable for large-scale industrial production, unable to prevent yarn slipping well, and low production efficiency, etc. The effect of preparation stability and preparation efficiency, reducing labor intensity and improving winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

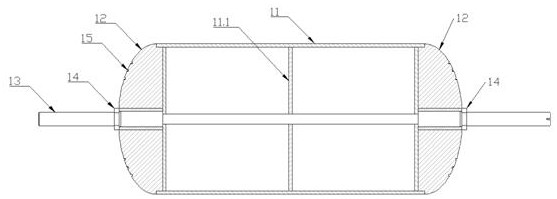

[0040] The following will pass the attached Figure 1~4 And the examples further describe the present invention.

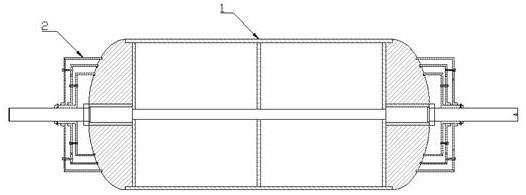

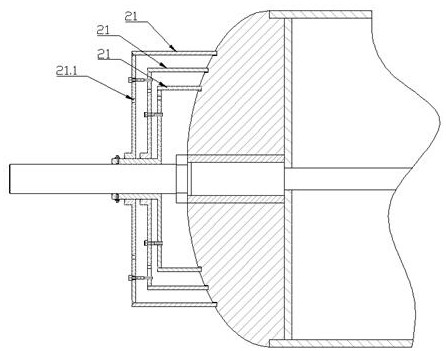

[0041] A forming device for large-size winding composite material loops, comprising a winding forming assembly 1 with a complete shaft and two ends of the seal head, characterized in that the outside of the two ends of the winding forming assembly 1 is equipped with a detachable ring yarn stopper assembly 2. The said ring-shaped yarn blocking component 2 is coaxially arranged with the winding forming component 1, and protrudes outward from the head doffing position of the winding forming component 1 in the axial direction, so as to prevent the yarn from falling in the head of the winding forming component 1 The doffing position slips off.

[0042] Such as figure 1 As shown, the annular yarn stopper assembly 2 is installed on the outside of the head of the winding forming assembly 1. The annular yarn stopper assembly 2 and the winding forming assembly 1 are coaxially a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com