Flexible lifting system for crane

A crane and flexible technology, applied in the field of flexible lifting system for cranes, can solve the problems that the wire rope cannot be found by the operators on the ground, reduce the lifting efficiency of the crane, and the lifting height of the crane is high, so as to improve the lifting efficiency, light weight, The effect of excellent bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

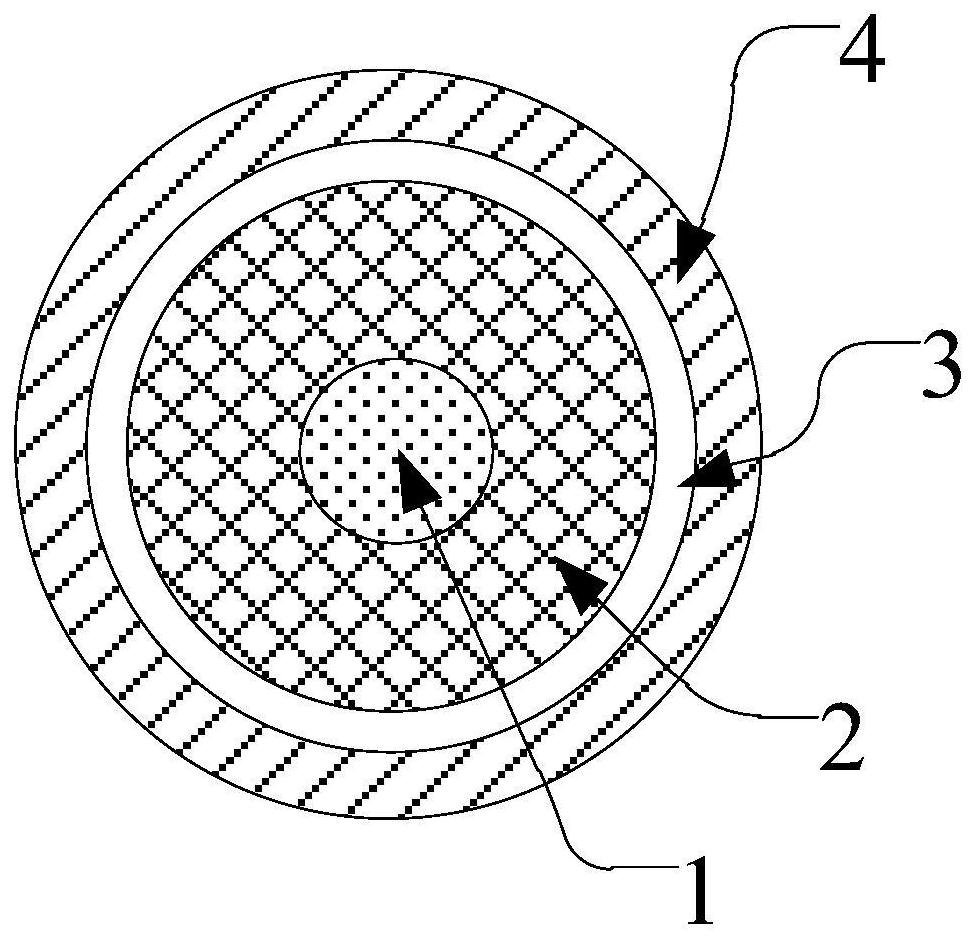

[0041]figure 1 It is a structural schematic diagram of the flexible suspension rope disclosed in Example 1.

[0042] In Embodiment 1, the flexible suspension rope includes a control core 1 , a load-bearing layer 2 , a warning layer 3 and a protective layer 4 arranged in sequence from the inside to the outside. Among them, the control core 1 is braided by 32 polyester fiber strands, including 16 strands in the Z twist direction and 16 strands in the S twist direction. The diameter of the control core 1 is 3 mm, and the braiding pitch is 7 mm. The load-bearing layer 2 is formed by braiding 12 high-molecular-weight polyethylene fiber strands on the control core 1, including 6 strands of S-twisted strands and 6 strands of Z-twisted strands, and the diameter of the load-bearing layer 2 is 24mm; the warning layer 3 is formed by wrapping red non-woven fabric outside the load-bearing layer 2; the protective layer 4 is formed by weaving 48 strands of polyester fiber strands outside the...

Embodiment 2

[0044] In Embodiment 2, the flexible suspension rope includes a control core, a load-bearing layer, a warning layer and a protective layer arranged sequentially from the inside to the outside. Among them, the control core is braided by 32 polyester fiber strands, including 16 strands in the Z-twisting direction and 16 strands in the S-twisting direction. The diameter of the control core is 2 mm, and the braiding pitch is 4 mm; The force layer 2 is formed by braiding 12 strands of high molecular weight polyethylene fiber strands on the control core, including 6 strands of S-twisted strands and 6 strands of Z-twisted strands. The diameter of the load-bearing layer is 20mm; the warning layer It is formed by wrapping red non-woven fabric outside the load-bearing layer; the protective layer is formed by weaving 48 strands of polyester fiber strands outside the warning layer, including 24 strands of Z-twisted strands and 24 strands of S-twisted strands. The diameter of the flexible ...

Embodiment 3

[0046] In Embodiment 3, the flexible suspension rope includes a control core, a load-bearing layer, a warning layer and a protective layer arranged in sequence from the inside to the outside. Among them, the control core is braided by 32 polyester fiber strands, including 16 strands in the Z twist direction and 16 strands in the S twist direction. The diameter of the control core is 3 mm, and the braiding pitch is 7 mm; The force layer is formed by braiding 12 strands of high molecular weight polyethylene fiber strands on the control core 1, including 6 strands of S-twisted strands and 6 strands of Z-twisted strands. The diameter of the load-bearing layer is 24mm; the warning layer It is formed by wrapping orange non-woven fabric outside the load-bearing layer; the protective layer is formed by weaving 48 strands of polyester fiber strands outside the warning layer, including 24 strands of Z-twisted strands and 24 strands of S-twisted strands. The diameter of the flexible slin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com