Cylinder, cylinder device, and working vehicle

A cylinder device and cylinder barrel technology, which is applied to fluid pressure actuators, cylinders, manufacturing tools, etc., can solve the problems of cylinder lengthening, cylinder overall weight, cracking, etc., to prolong life, reduce weight, and improve fatigue The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

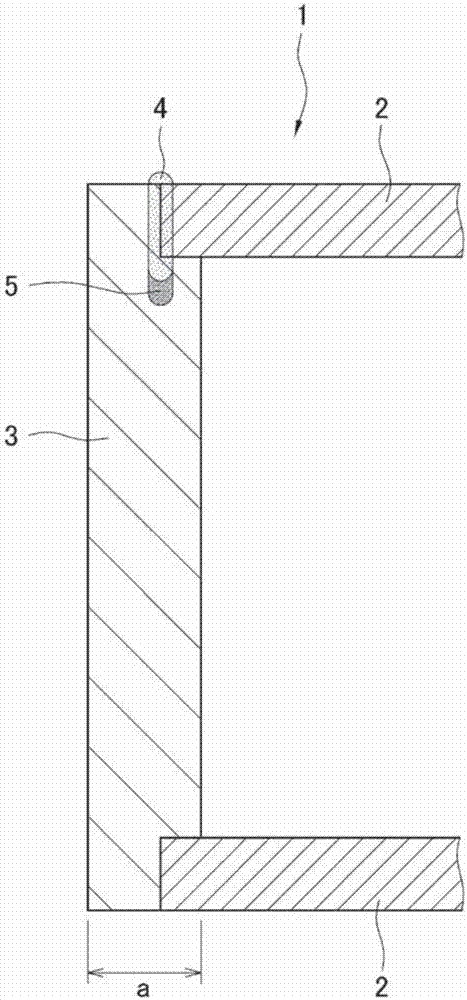

[0032] The cylinder 1 according to the embodiment of the present invention will be described based on the drawings. figure 1 A cross-sectional view showing the end portion of the cylinder 1 according to the embodiment of the present invention cut along a plane including the axis of the cylinder tube 2 .

[0033] The cylinder 1 of the present embodiment is a cylinder 1 constituting a single-rod type cylinder device operated by hydraulic pressure, and includes a cylinder tube 2 , a cylinder head 3 , and a rod cover. The cylinder tube 2 has a thin-walled cylindrical shape and constitutes a cylinder portion of the cylinder 1 . The cylinder head 3 constitutes an end portion without a hole for a piston rod in a single-rod cylinder. The cylinder head 3 has a substantially flat cylindrical shape, and may have coupling pin holes and the like for attachment to other equipment or the like. The rod cover constitutes the other end of the cylinder 1 . The connecting rod cover has a hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com