Optimal stress angle adjusting device for automobile crane jib

An angle adjustment device, a technology for truck cranes, applied in cranes, transportation and packaging, etc., can solve the problem of not being able to maintain all the time, and achieve the effects of maintaining stable movements, optimizing spacing, and increasing lifting loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

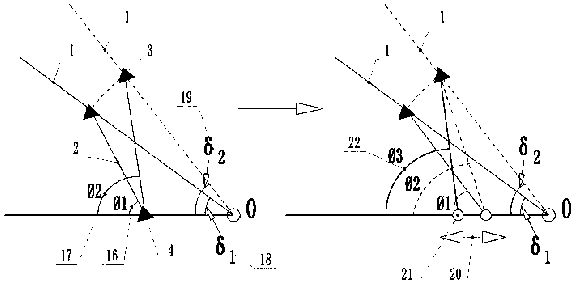

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0021] The invention relates to a device for adjusting the optimum force-bearing angle of a boom of a truck crane, which can better adjust the stress-bearing angle of the boom by installing the device on the truck crane.

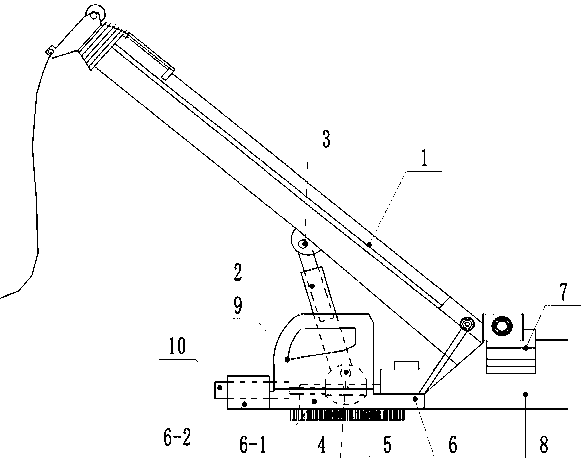

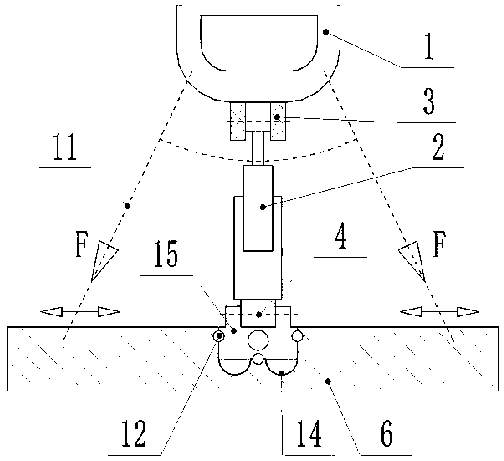

[0022] The present invention is installed on the truck crane, as figure 1 , figure 2 As shown, the non-lifting end of the boom 1 is hinged and fixed on the rotating chassis 8, and the tail end is fixedly equipped with a counterweight 7, the rotating chassis 8 is fixed on the side of the main chassis 6, and a turntable is installed at the bottom of the middle position of the main chassis 6 5. The cab 9 is installed on the top of the main chassis 6, and the support cylinder 2 is installed between the boom 1 and the main chassis 6. The bottom end of the support cylinder 2 is adjusted by the optimal adjustment device; the optimal adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com