A slip-fit motor rotor structure

A motor rotor and slip-fit technology, which is applied in the field of slip-fit motor rotor structure, can solve the problems of winding shedding, poor stability of square structure, and unstable operation of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

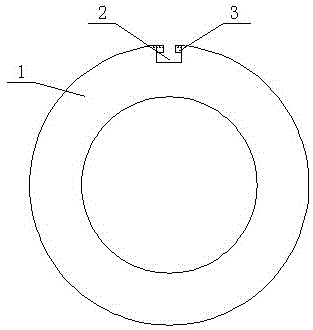

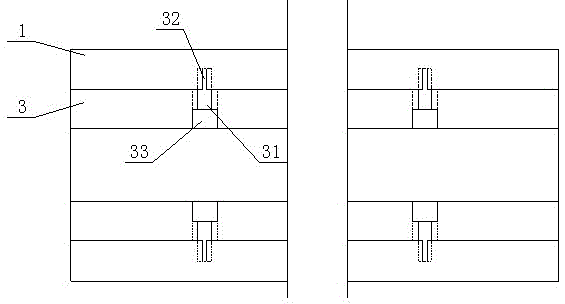

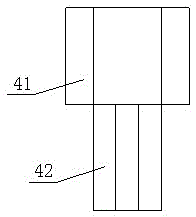

[0013] Such as Figure 1-4 As shown, the slip-fit motor rotor structure according to the embodiment of the present invention includes a rotor body 1, which is integrally formed, and a number of rotor slots 2 arranged longitudinally and uniformly are arranged on the outer circumference of the rotor body 1. The two outer sides of the mouth are respectively equipped with beading bars 3, so that the space for accommodating the windings in the rotor slot 2 forms a "convex" shape, and at least two first transverse trapezoidal grooves 31 are arranged on the beading bar 3, corresponding to the The position of the first trapezoidal groove 31 is provided with a second trapezoidal groove 32 on the inner wall of the rotor body 1, the length of the top side of the first trapezoidal groove 31 is equal to the length of the bottom side of the second trapezoidal groove 32, An integrally formed first trapezoidal block 41 and a second trapezoidal block 42 are provided in the first trapezoidal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com