Solid-liquid separation device

A technology of solid-liquid separation and separation device, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing water flow resistance, impurity blocking of mesh filter materials, and inability to use for a long time, and achieves improvement of filtration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

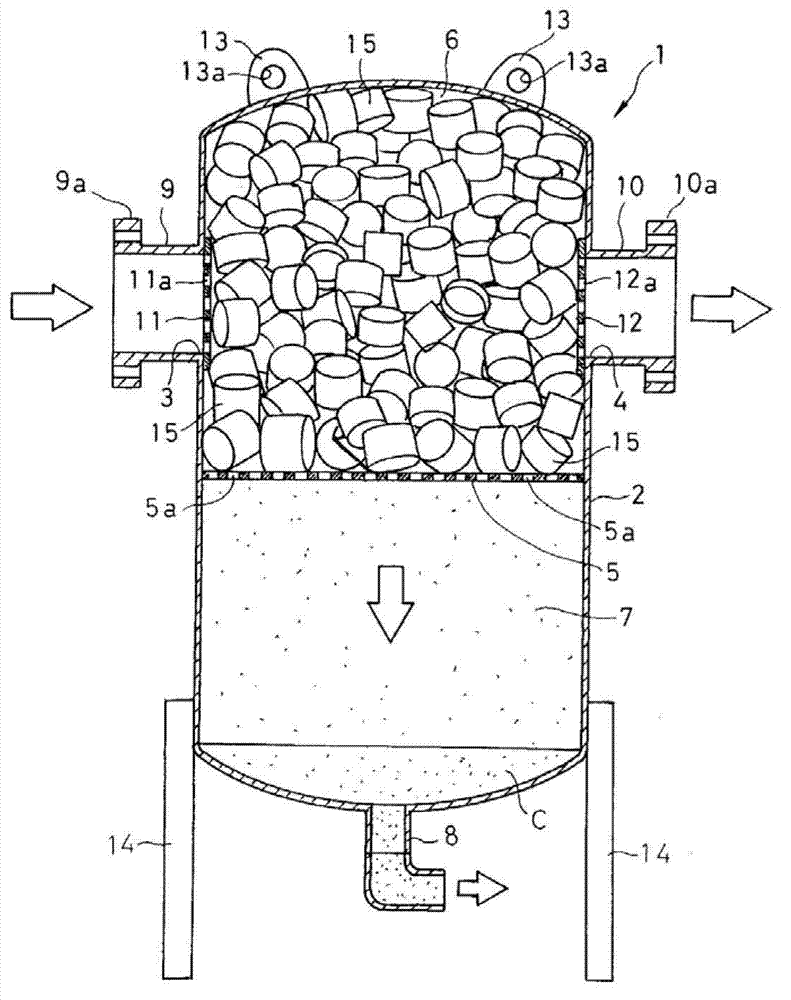

[0022] The following is the operation form of the present invention, please refer to the drawings for description.

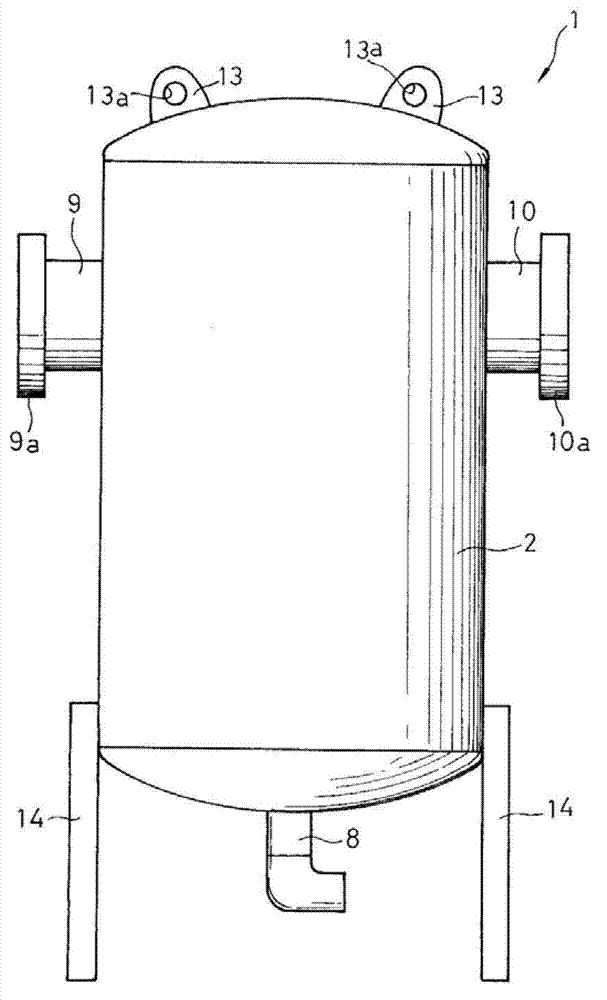

[0023] figure 1 It is a solid-liquid separation device. figure 2 It is the main body of the sealed cylindrical separation device of the device 1. The separation device host 2 is made of stainless steel.

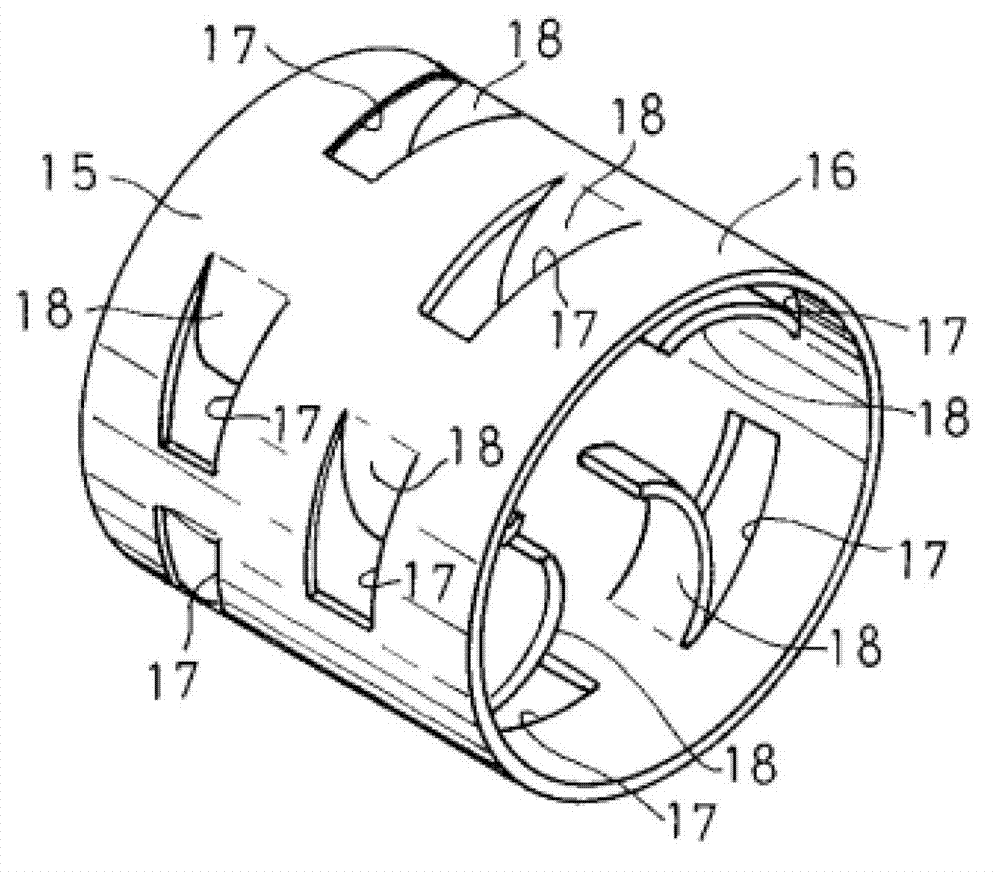

[0024] The top of this separating device main frame 2 is provided with water inlet 3 and water outlet 4, and a lower dividing plate 5 that has many apertures 5a is set at separating device main frame 2 bottoms, in order to partition the top of this separating device main frame 2 and The lower two parts. The upper filter chamber 6 is filled with many filter materials 15 arranged irregularly in multiple directions, and an impurity solid matter discharge port 8 is set at the bottom of the lower solid matter deposition chamber 7 . The volume ratio of the upper filter chamber 6 and the lower solid matter deposition chamber 7 is 55:45, and can be properly set ac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap