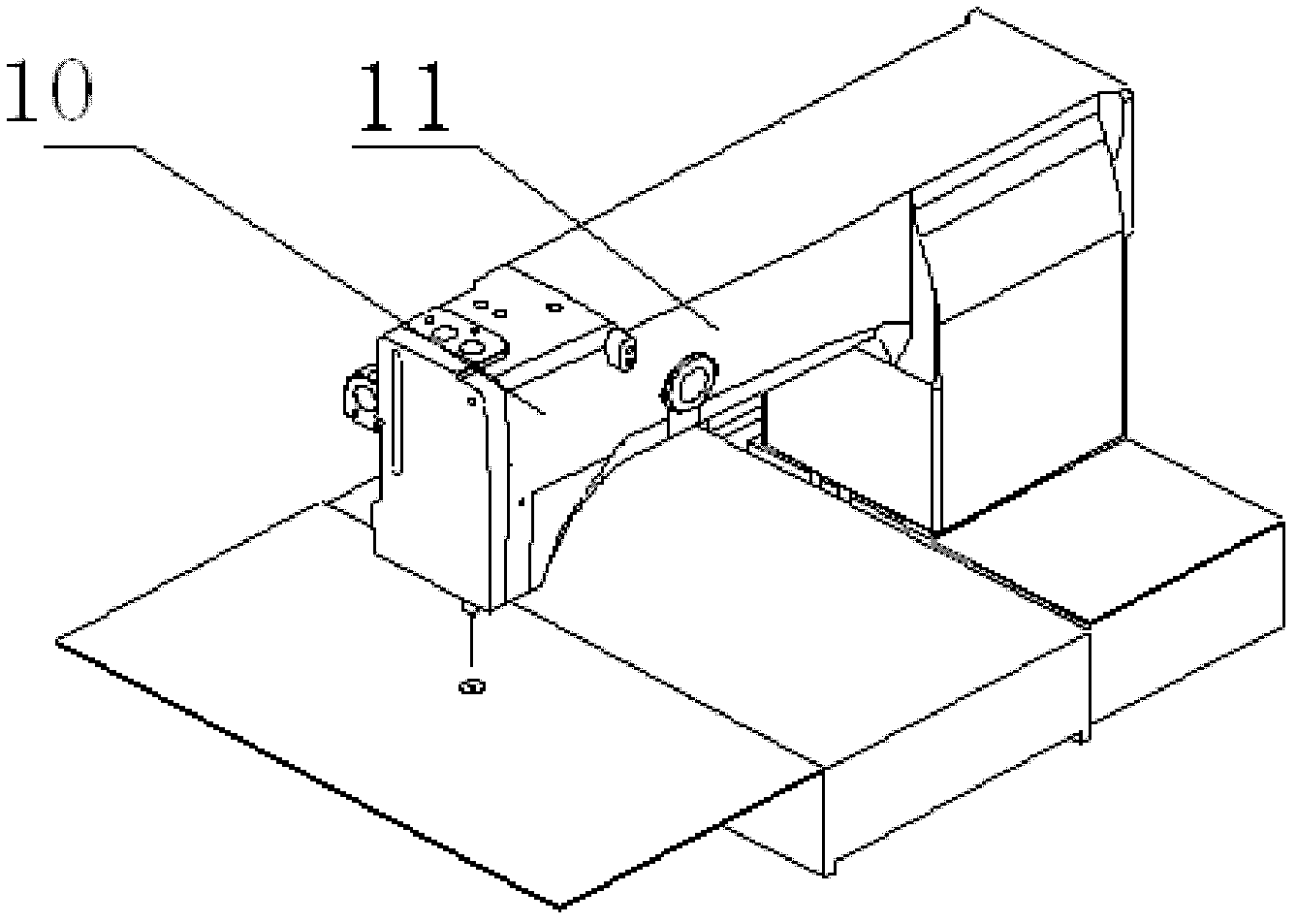

Machine head liftable structure in sewing machine

A lifting structure, sewing machine technology, applied in the field of sewing machines, can solve the problem of poor placement of materials before sewing, and achieve the effect of increasing the material discharge space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

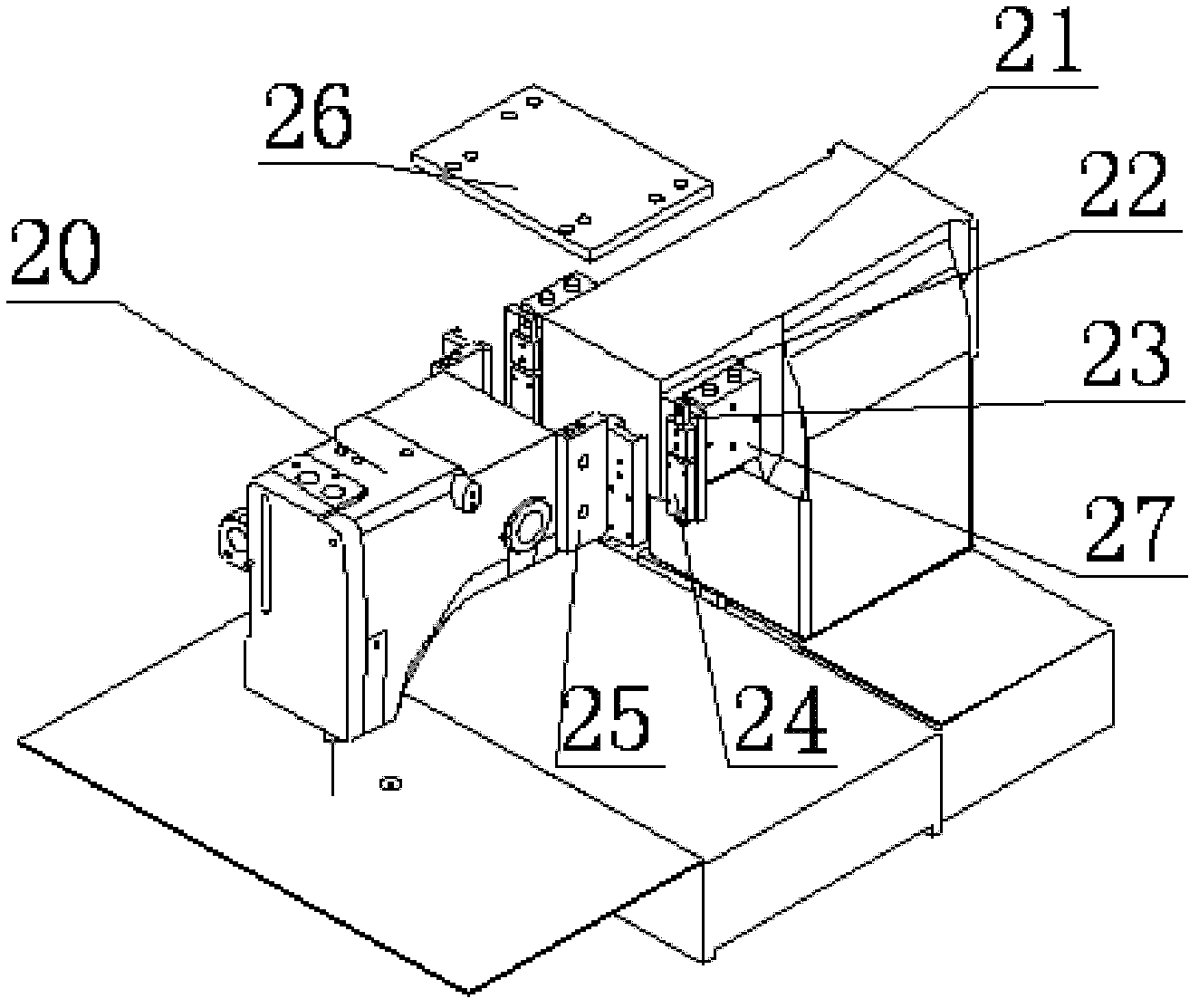

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0010] Depend on figure 2 Visible: the present invention comprises: machine head 20 and machine arm 21; Fixing seat 22 is arranged respectively at described machine arm 21 front end both sides; The front end of described fixing seat 22 is fixed linear guide rail 23; There are two sliders 24; corresponding to the arm 21, sliding seats 25 are arranged on both sides of the machine head 20; the two sliders 24 are fixed on the sliding seats 25; Also includes: a lifting plate 26, two cylinders 27; the two cylinders 27 are respectively fixed on the fixed seat 22 of the machine arm 21; the lifting plate 26 is connected with the cylinder rod end on the cylinder 27 and the sliding seat 25 respectively .

[0011] When it is necessary to sew fluffy materials, especially car seat cushions and pillows, driven by the cylinder rod, the sliding seat is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com