Post for highway guardrail

A highway and column technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problems of increased cost, increased use cost, difficult to achieve results, etc., to save costs, strengthen anti-theft protection, and facilitate replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

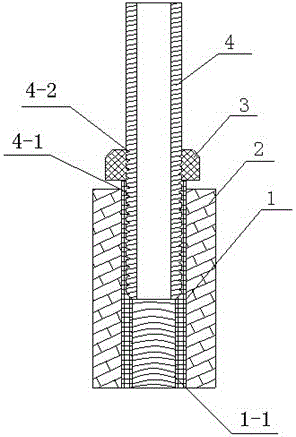

[0021] Such as figure 1 As shown, a column for a highway guardrail includes an upper column 4 and a lower column 1, the lower column 1 is embedded in the ground concrete 2, the upper column 4 is connected and fixed with the lower column 1 through threads, and a fixing nut is provided at the joint 3. The fixing nut 3 is sleeved on the outer periphery of the upper column. The lower column 1 is a hollow cylinder with an internal thread 1-1 inside; the outer periphery of the lower end of the upper column 4 is provided with a first thread 4-1 meshing with the internal thread 1-1, and the first thread 1 -4 is provided with a second section of thread 4-2 that matches the fixed nut 3, and the rotation direction of the first section of thread 4-1 is opposite to that of the second section of thread 4-2, such as the first section of thread 4- 1 is a right-handed thread, then the second section of thread 4-2 is a left-handed thread; in order to ensure the protection strength of the colum...

Embodiment 2

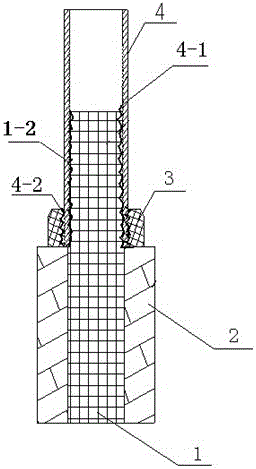

[0023] Such as figure 2 As shown, a column for a highway guardrail includes an upper column 4 and a lower column 1, the lower column 1 is embedded in the ground concrete 2, the upper column 4 is connected and fixed with the lower column 1 through threads, and a fixing nut is provided at the joint 3. The fixing nut 3 is sleeved on the outer periphery of the upper column. The outer periphery of the lower column 1 is provided with an external thread 1-2, the upper column 4 is a hollow cylinder, and the lower end is provided with a first section thread 4-1 engaged with the external thread 1-2, and the outer circumference of the upper column 4 There is a second section of thread 4-2 matched with the fixing nut 3, and the rotation direction of the first section of thread 4-1 is opposite to that of the second section of thread 4-2. For example, the first section of thread 4-1 is If the thread is left-handed, the second thread 4-2 is a right-handed thread; in order to ensure the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com