Rotary impact type pneumatic roofbolter

A rock bolt rig, percussion technology, applied in the direction of installation of rock bolts, driving devices for rotary combined drilling, drilling equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

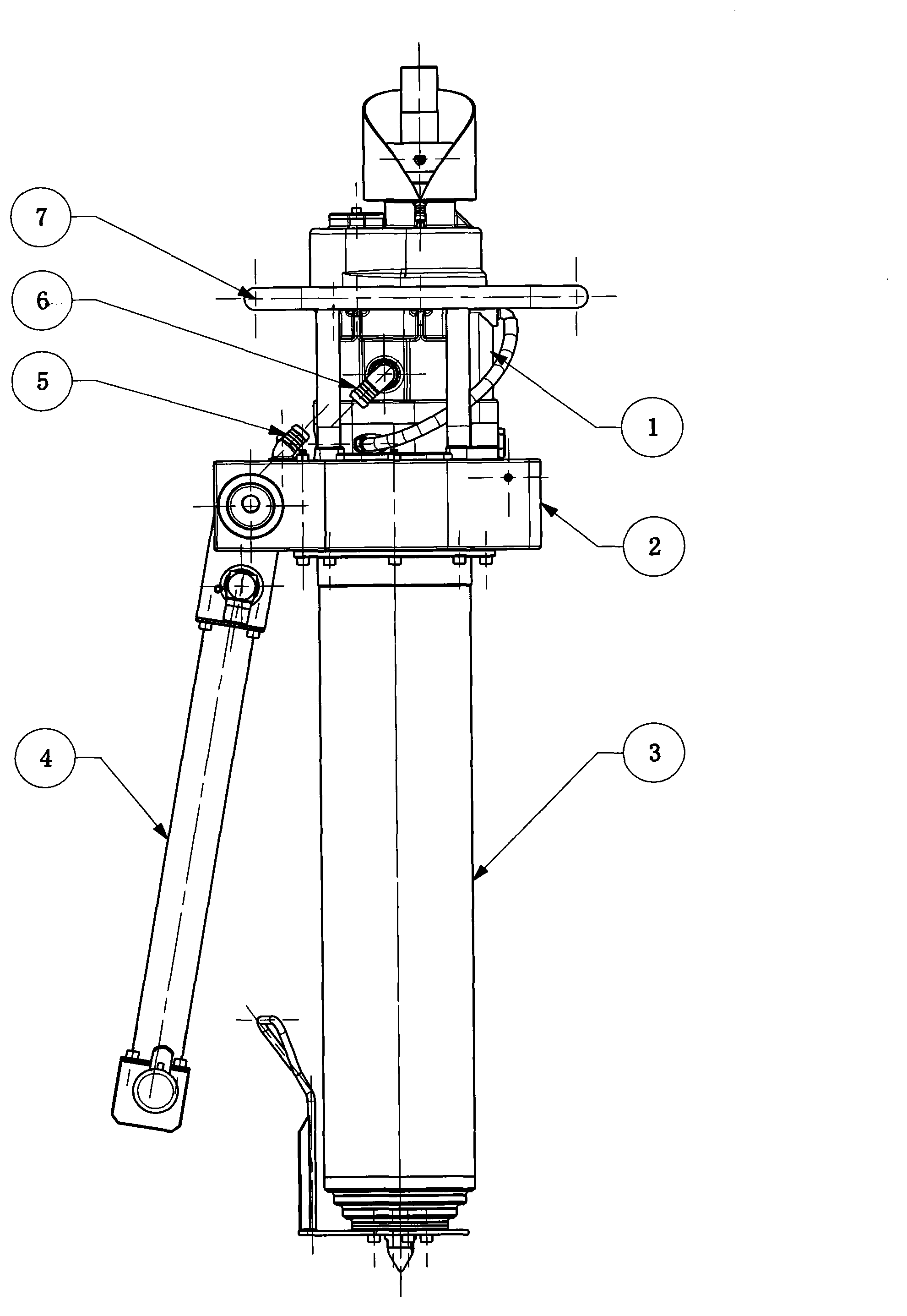

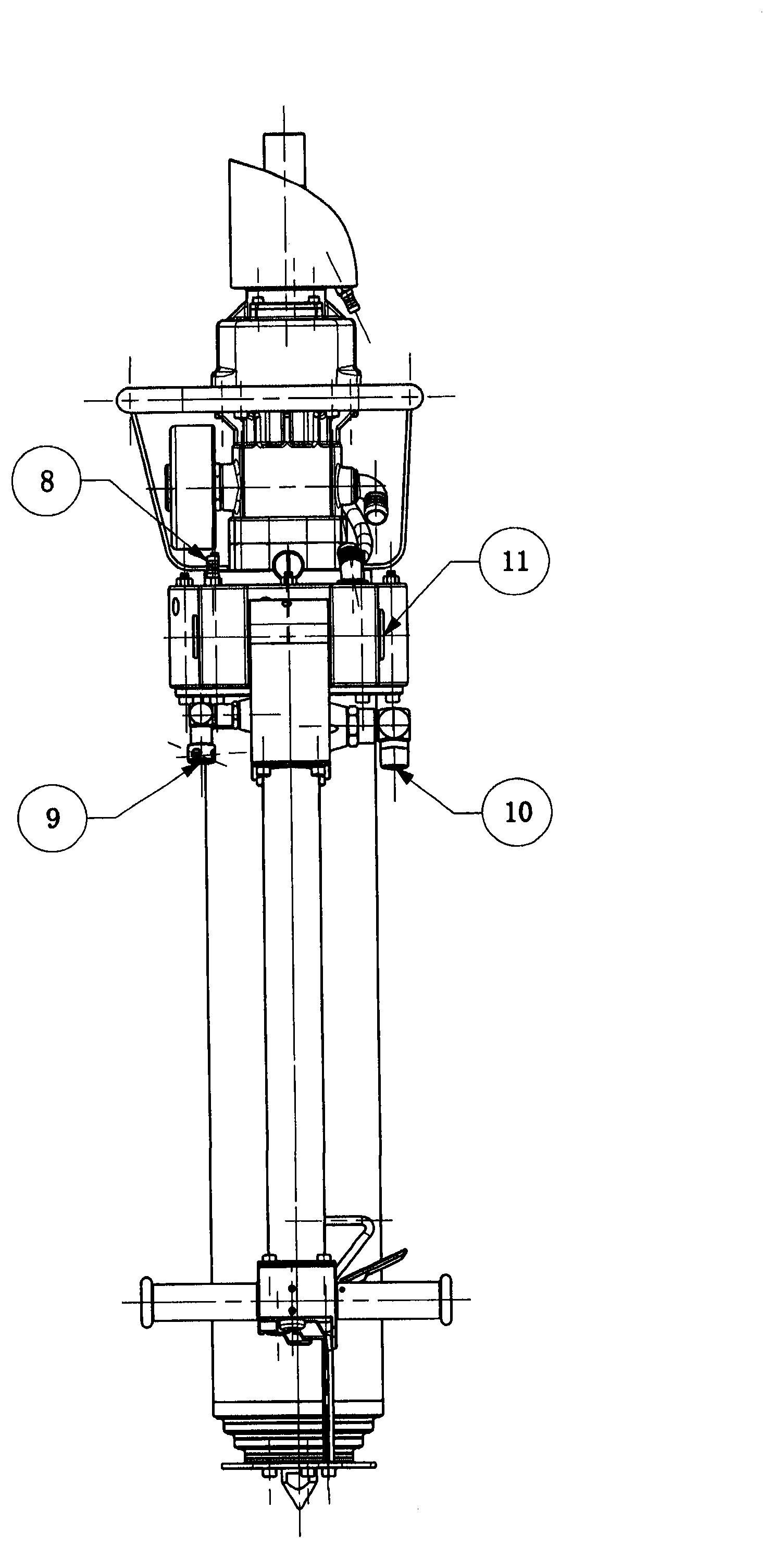

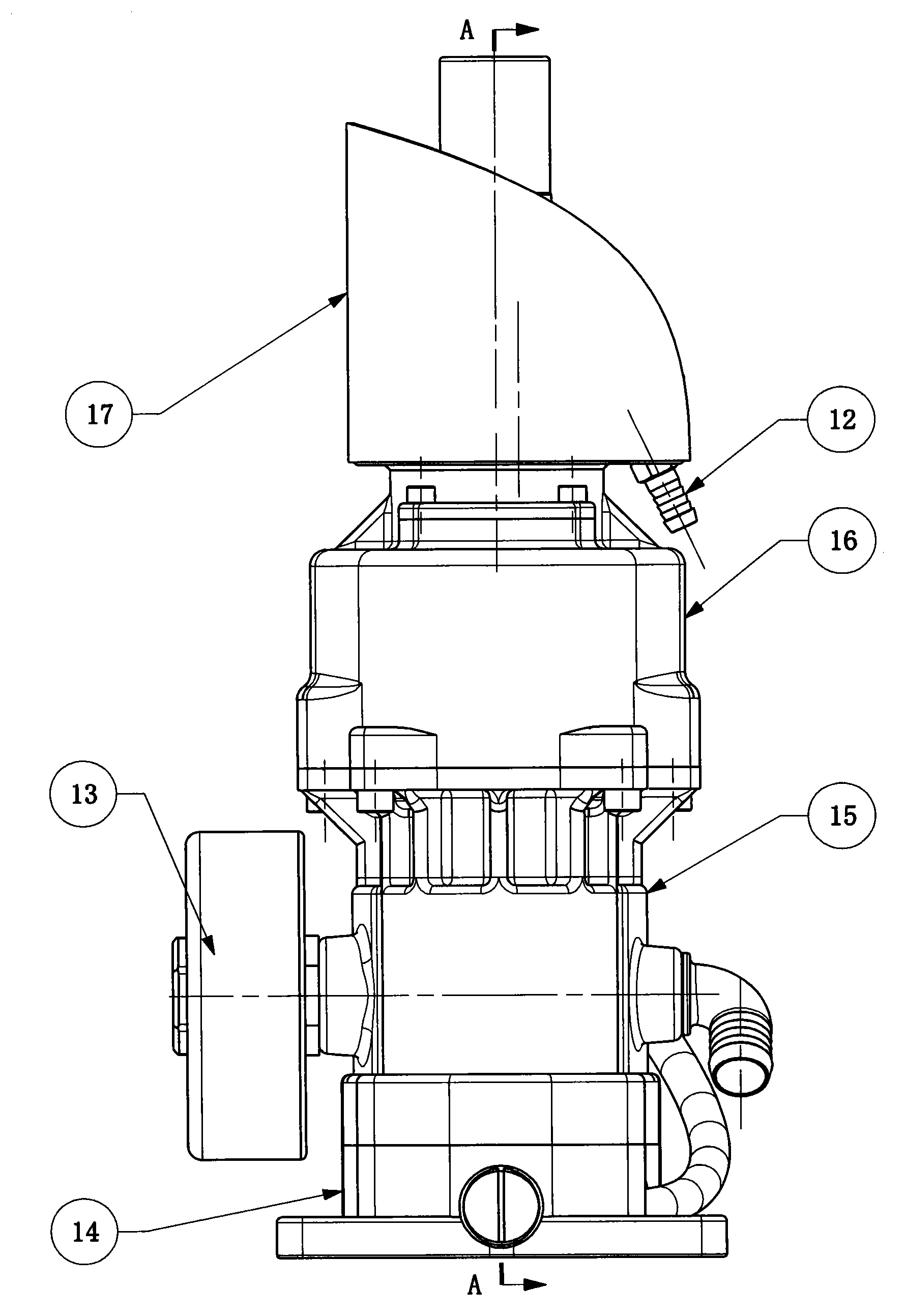

[0005] [Example 1] The rotary impact pneumatic rock bolter is mainly composed of: machine head (1), body (2), outrigger (3), control arm (4), etc., machine head (1) and outrigger (3) ) and the motor retainer (7) are fixed on the body (2) with screws, the control arm (4) is hinged on the body (2) with the distribution shaft (11), and the water jacket (19) is fixed on the transmission box (16) , and form sealing with sealing ring and main shaft (21) top, air outlet joint (5) of body links to each other with motor inlet joint (6) with pipeline, body water outlet joint (8) links to each other with main shaft water inlet joint (12) with pipeline. Its machine head (1) part is mainly made up of: pneumatic impact mechanism, gear transmission mechanism, pneumatic gear motor mechanism. The structure of the pneumatic gear motor mechanism is: bearing housing I (37) and bearing housing II (38) are fixed on the lower end of the motor body (15), the motor driven gear (31) and the motor drivi...

Embodiment 2

[0007] [Example 2] In Example 1: the drill sleeve (18) and the main shaft (21) can be integral, and the control valve joint I (29) is connected with the control valve joint II (63) with the control valve air pipe (30), This connection can be provided with guide holes in the motor body (15) and the control block (14).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com