Siren horn of urban rail vehicle

A technology of urban rail vehicles and horns, which is applied in the direction of sounding equipment, lifting valves, instruments, etc., can solve the problems of difficult control of the size of fillings, blockage of pipelines, and inability to adjust the flow area, so as to achieve a simple and reliable flow adjustment scheme. Easy installation and disassembly, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

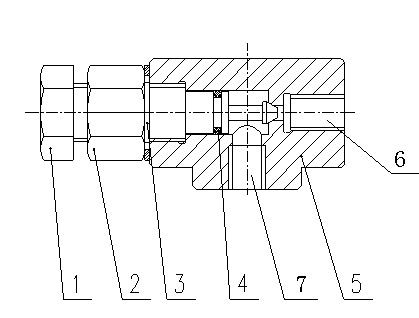

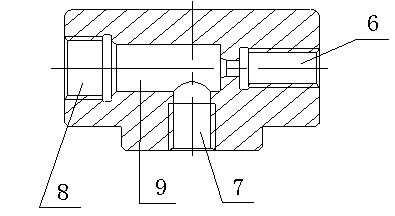

[0015] Such as figure 1 Shown, a kind of siren horn of urban rail vehicle comprises the pipeline that feeds gas to the air inlet of horn, and the regulating valve that regulates horn volume is installed on the pipeline, and this regulating valve comprises valve body 5, is provided with in valve body 5 and is connected with pipeline. The valve body air inlet 6 and the valve body air outlet 7 connected with the horn air inlet, the valve body air inlet 6 is connected with the pipeline through a ferrule, and the valve body air outlet 7 and the horn air inlet are respectively equipped with straight joints, And connect the two straight-through joints through ferrules, the valve body air inlet 6 and the valve body air outlet 7 are communicated through the connecting hole; the adjusting mechanism for controlling the amount of gas entering the valve body air inlet 6 is installed in the connecting hole .

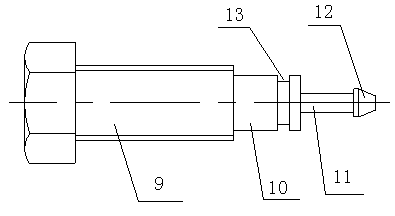

[0016] Such as figure 2 As shown, the axial centerline of the valve body i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com