Positive-pressure vortex type disassembly-free washable range hood

A range hood and eddy current technology, which is applied in the field of positive pressure eddy current range hoods without dismantling and cleaning, can solve the problems of increasing the resistance of the motor and the impeller, increasing the user's economic expenditure, affecting the service life of the motor in the working state of the impeller, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

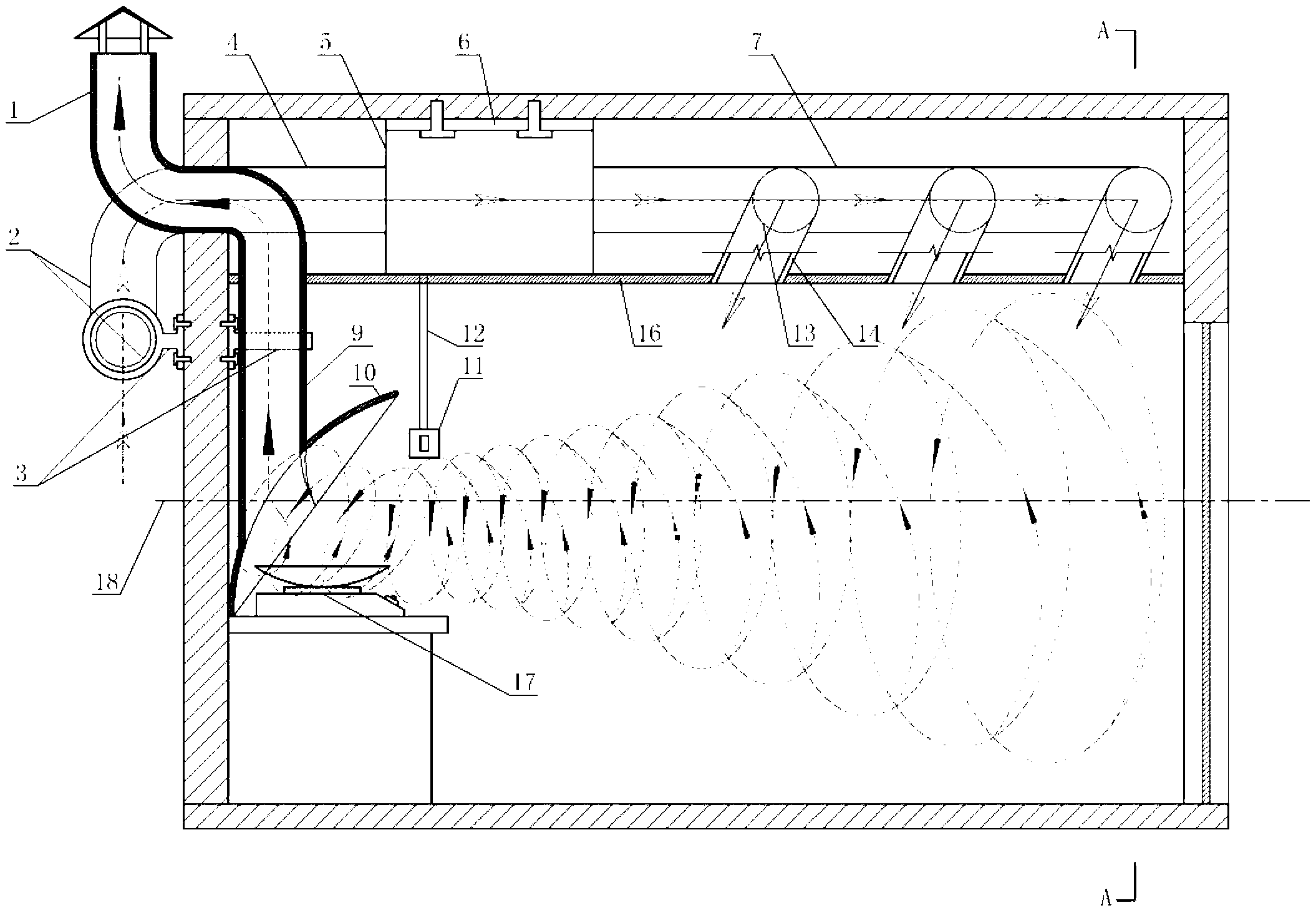

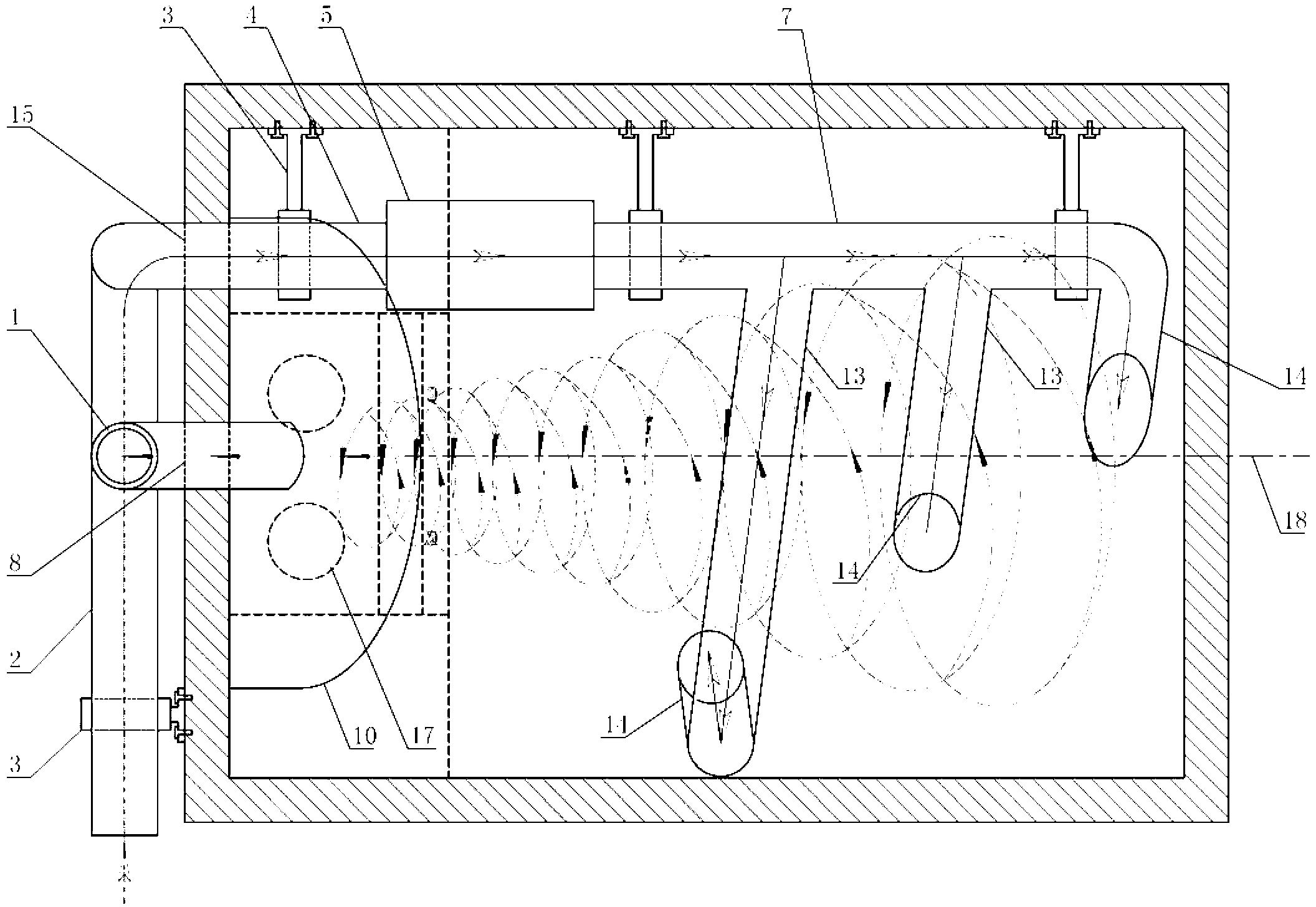

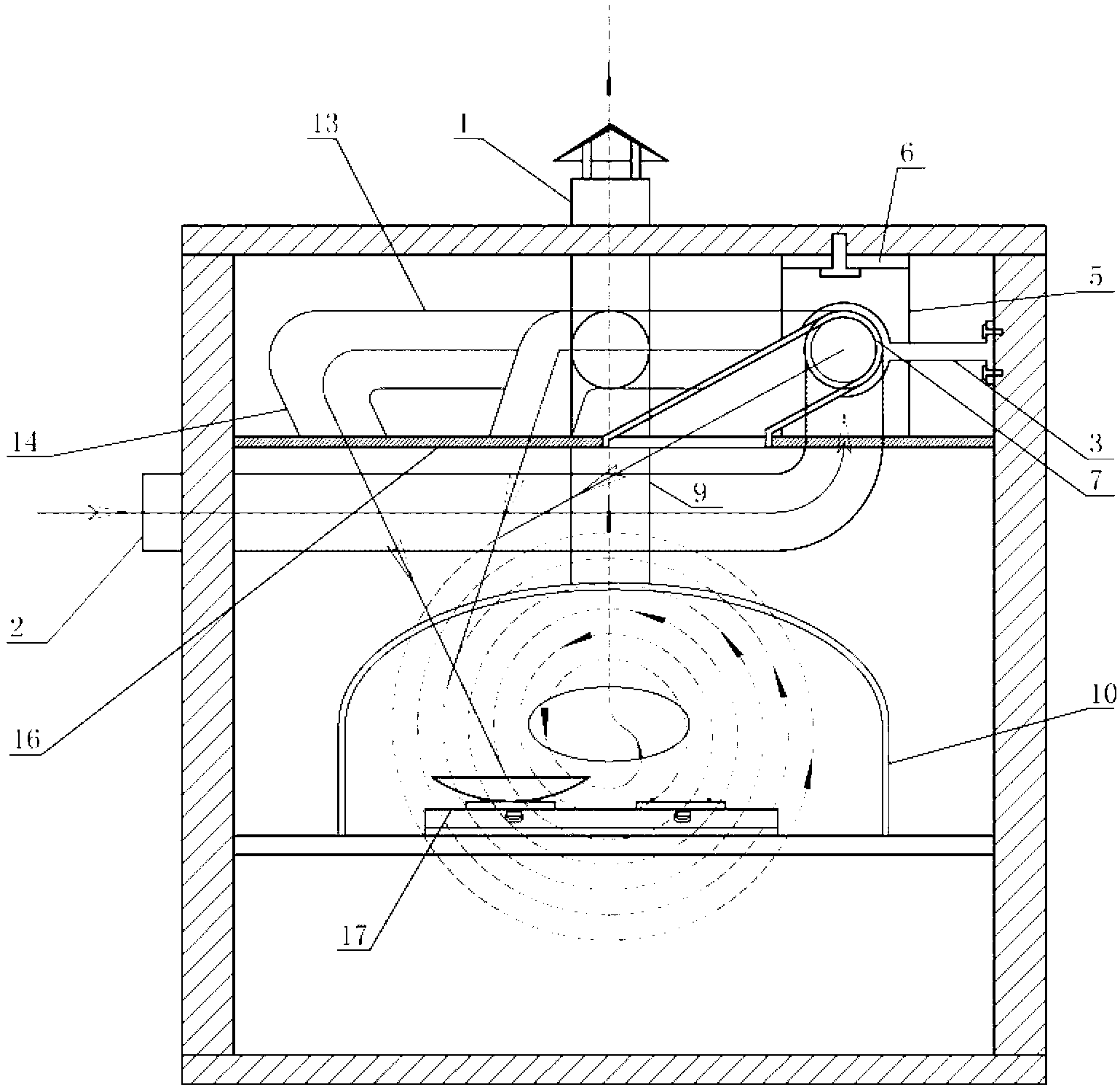

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Positive pressure vortex type non-disassembly and washable range hood consists of smoke exhaust outer pipe 1, air inlet outer pipe 2, fixed ring 3, air inlet front pipe 4, air pump 5, fixed frame 6, air inlet rear pipe 7, and exhaust wall Hole 8, smoke exhaust inner pipe 9, oil fume cover 10, air pump switch 11, lead 12, air inlet branch pipe 13, air inlet end pipe 14 and air inlet wall hole 15 constitute.

[0027] An exhaust wall hole 8 and an air inlet wall hole 15 are respectively opened on the outer wall of the kitchen, and both the exhaust wall hole 8 and the air inlet wall hole 15 are above the suspended ceiling 16 .

[0028] The outer smoke exhaust pipe 1 is installed on the outer surface of the kitchen exterior wall, the outer end of the smoke exhaust outer pipe 1 opens upwards, and the inner end of the smoke exhaust outer pipe 1 stretche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com