Tilt offset correction method for actuator

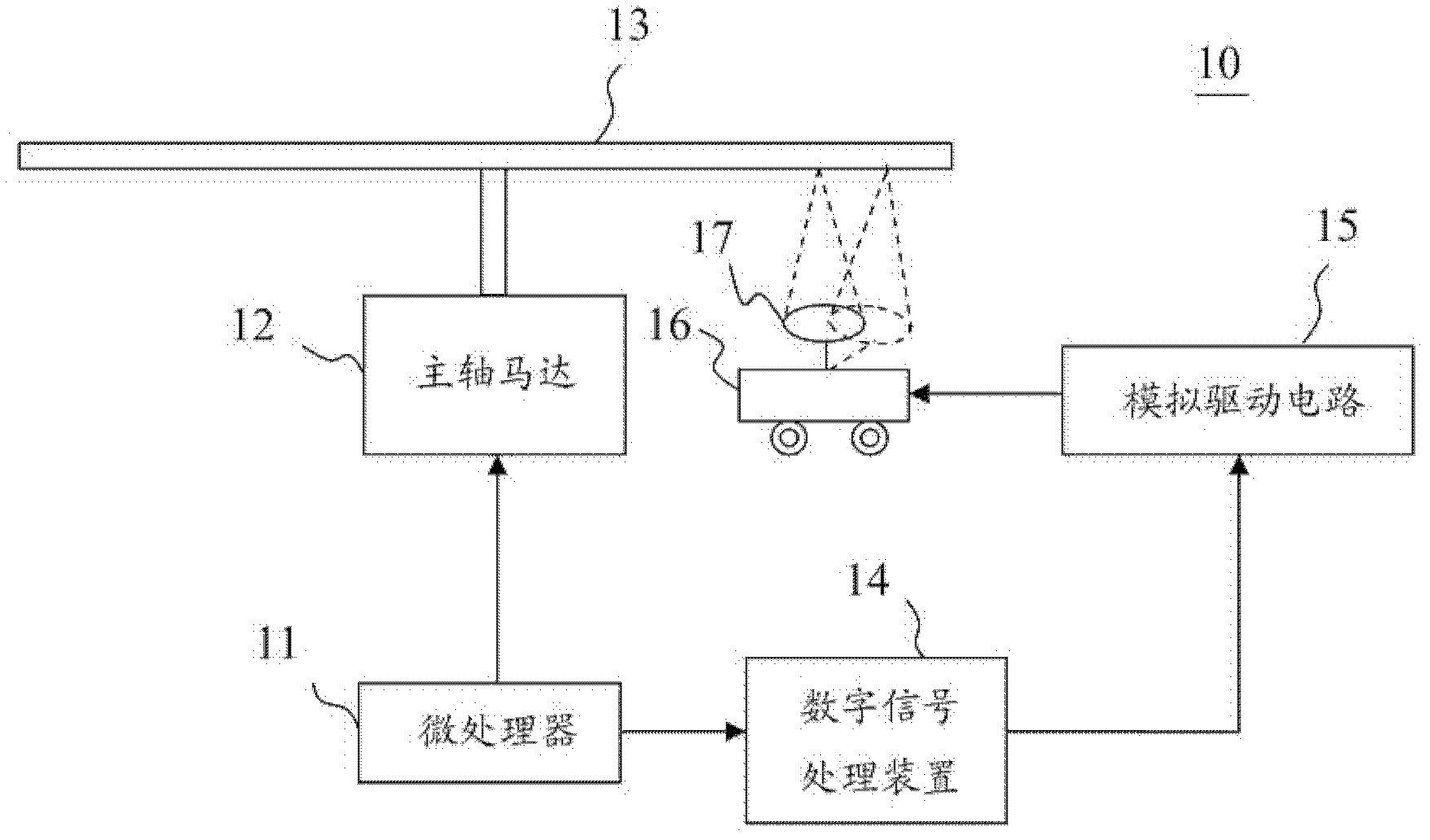

A technology of tilt offset and correction method, applied in the field of optical drives, which can solve problems such as affecting the quality of reading and writing of optical drives, inability to accurately move the control voltage, and crashing the read head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to achieve the above object, the present invention adopts the technical means and its effects, the preferred embodiments are given, and are described as follows in conjunction with the drawings.

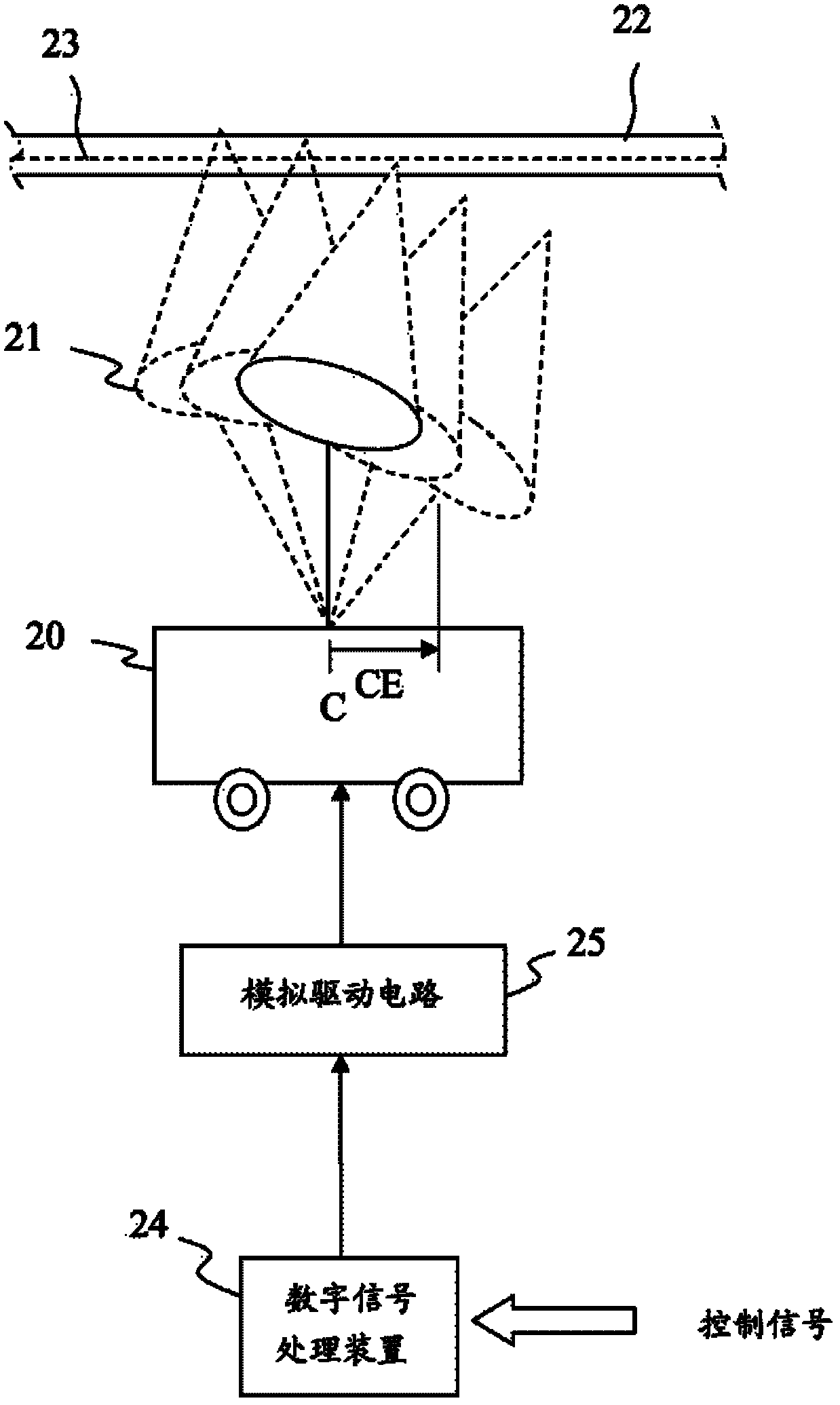

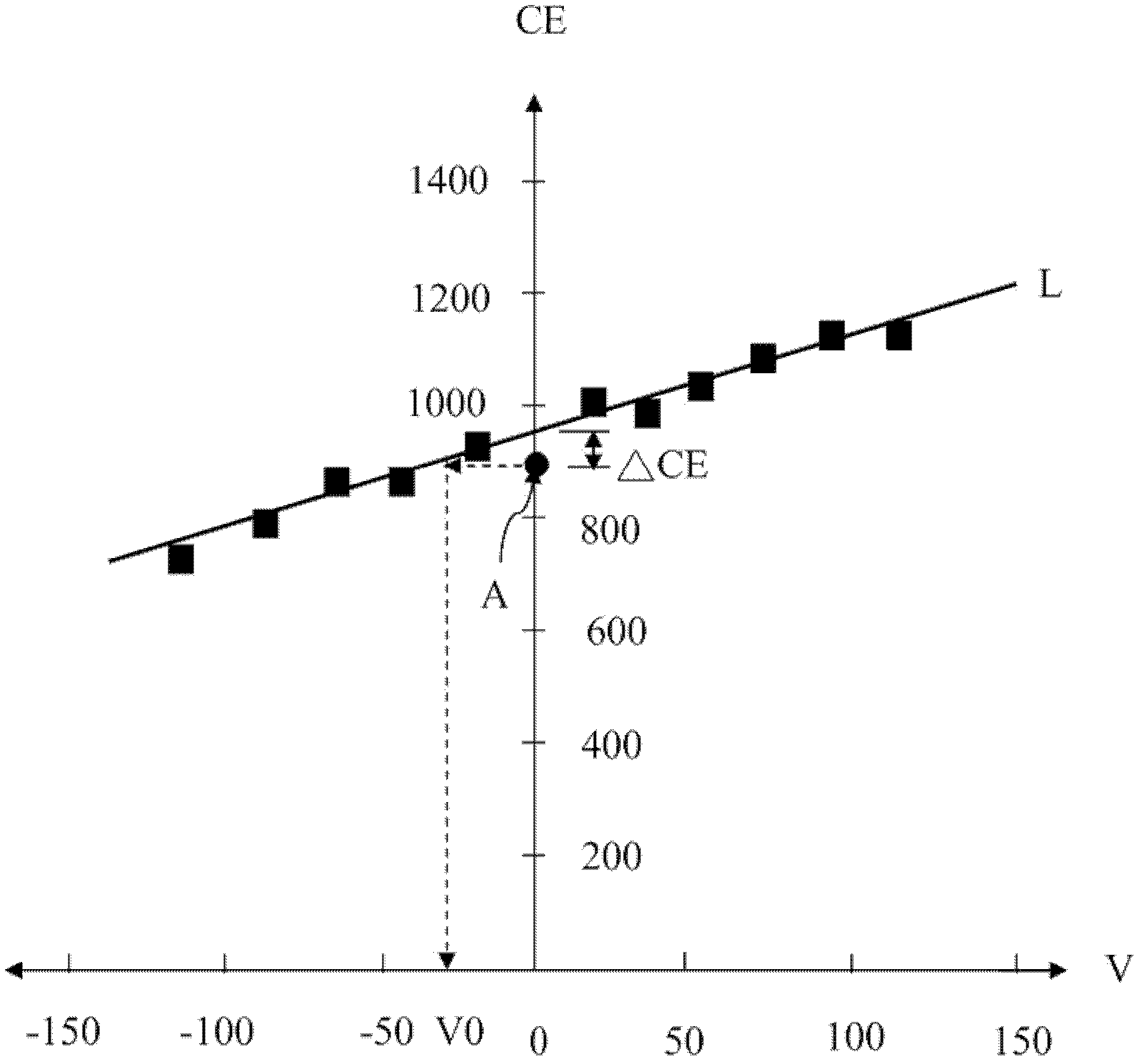

[0021] Please also refer to Figure 2 to Figure 3 , figure 2 It is a functional block diagram of the tilt offset correction of the actuator of the present invention, image 3 It is the approximate offset curve of the present invention. figure 2 Among them, the method for correcting the tilt offset of the actuator 20 in the embodiment of the present invention mainly corrects the tilt offset in the radial direction of the actuator 20. When correcting the tilt offset of the actuator 20, first move the actuator 20 up and down The objective lens 21 focuses the light beam projected by the objective lens 21 on the data layer 23 of the optical disc 22, reducing the interference caused by the actuator 20 driving the objective lens 21 to move up and down. Then output the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com