Plug with unplugging assisting function

A technology for pulling out the plug and the body of the plug, applied in the field of power supply or charger plug, can solve the problems of burnt connection, clamping and laborious metal conductive terminals that cannot be plugged, and achieve the effect of avoiding electric shock and avoiding the danger of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation form of the present invention is described in detail below in conjunction with accompanying drawing:

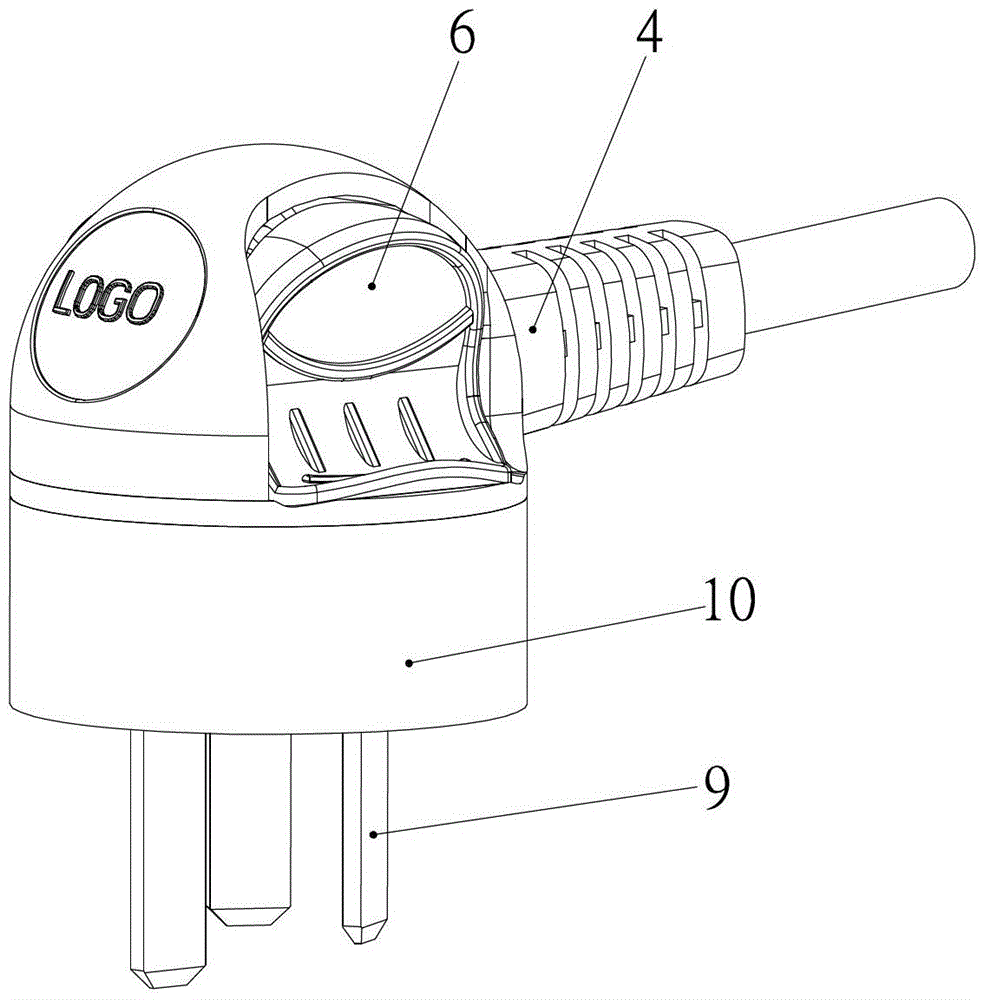

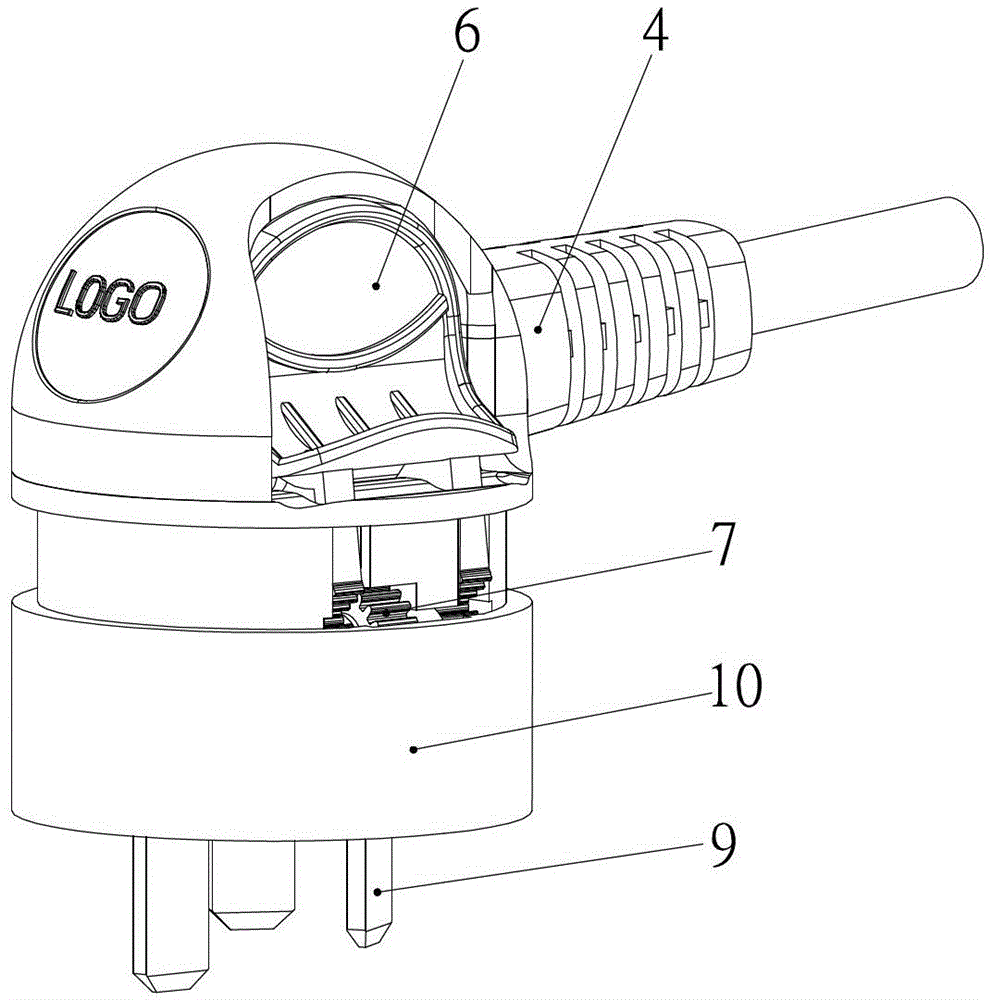

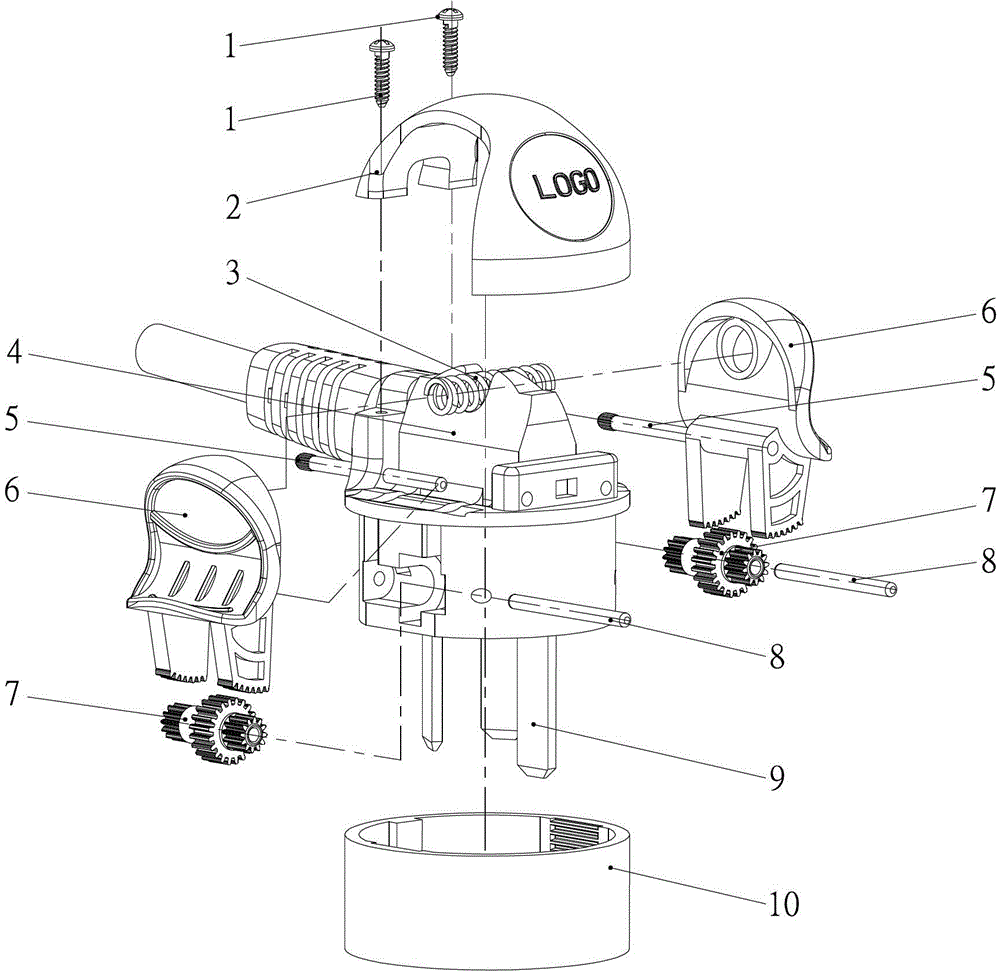

[0029] see figure 1 , figure 2 , image 3 , The power plug includes a plug body 4 , a conductive terminal 9 , key assemblies 6 and 3 , a transmission part 7 and a push part 10 . The conductive terminal is connected from the front end of the plug body, and the conductive terminal can be two-phase or three-phase, and the shape is a round head, a flat head or a combination of both.

[0030] combine image 3 , Figure 4A and Figure 4B , the button assembly includes two buttons 6 and a spring 3, the two buttons are arranged symmetrically on both sides of the plug body 4, pivotally connected to the plug body 4 through the positioning shaft 5 and the positioning hole 62, forming a labor-saving lever structure, the upper part of which is used It is the power arm for pressing, and the lower part is the resistance arm. The spring 3 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com