Plug-in base of plastic shell type electric appliance having multiple wiring functions

A plug-in, molded case technology, applied in the direction of circuits, electrical components, circuit breaker parts, etc., can solve the problems of increasing production and use costs, single wiring method, laborious and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

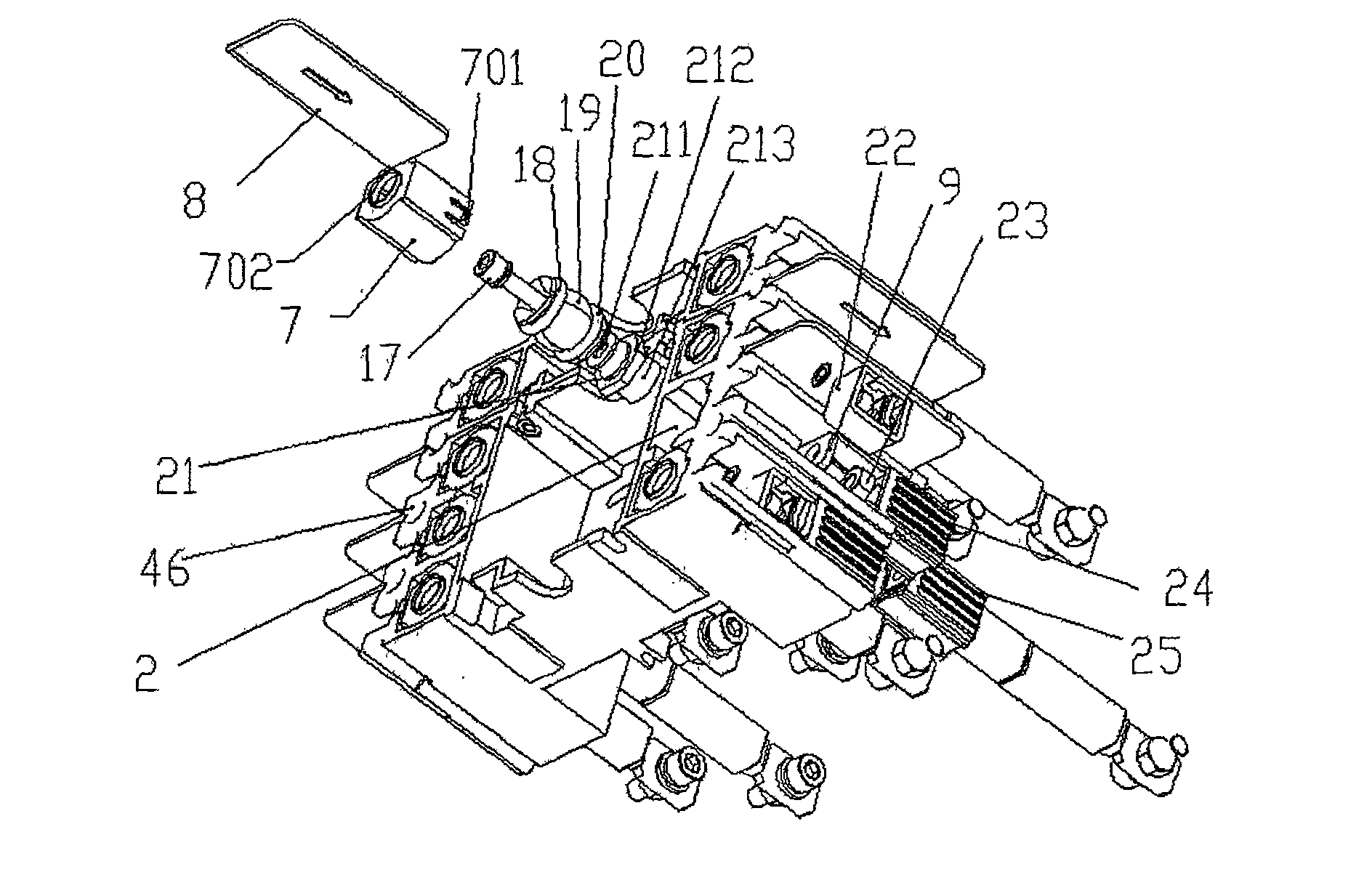

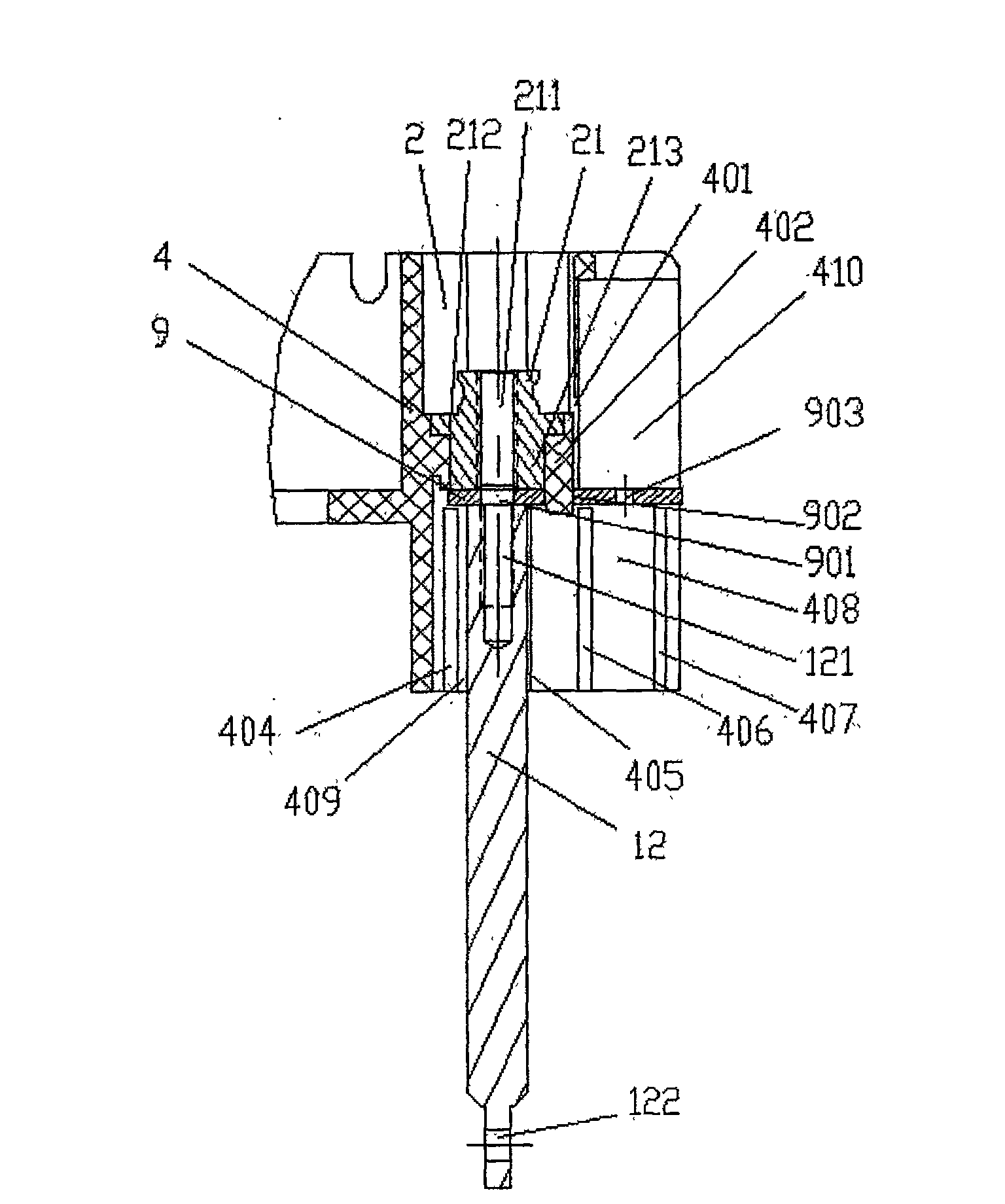

[0027] Taking a molded case circuit breaker as an example, an embodiment of the electrical plug-in base of the present invention will be described in detail with reference to the accompanying drawings. The plug-in base of the molded case electrical appliance of the present invention is not limited to the following embodiments.

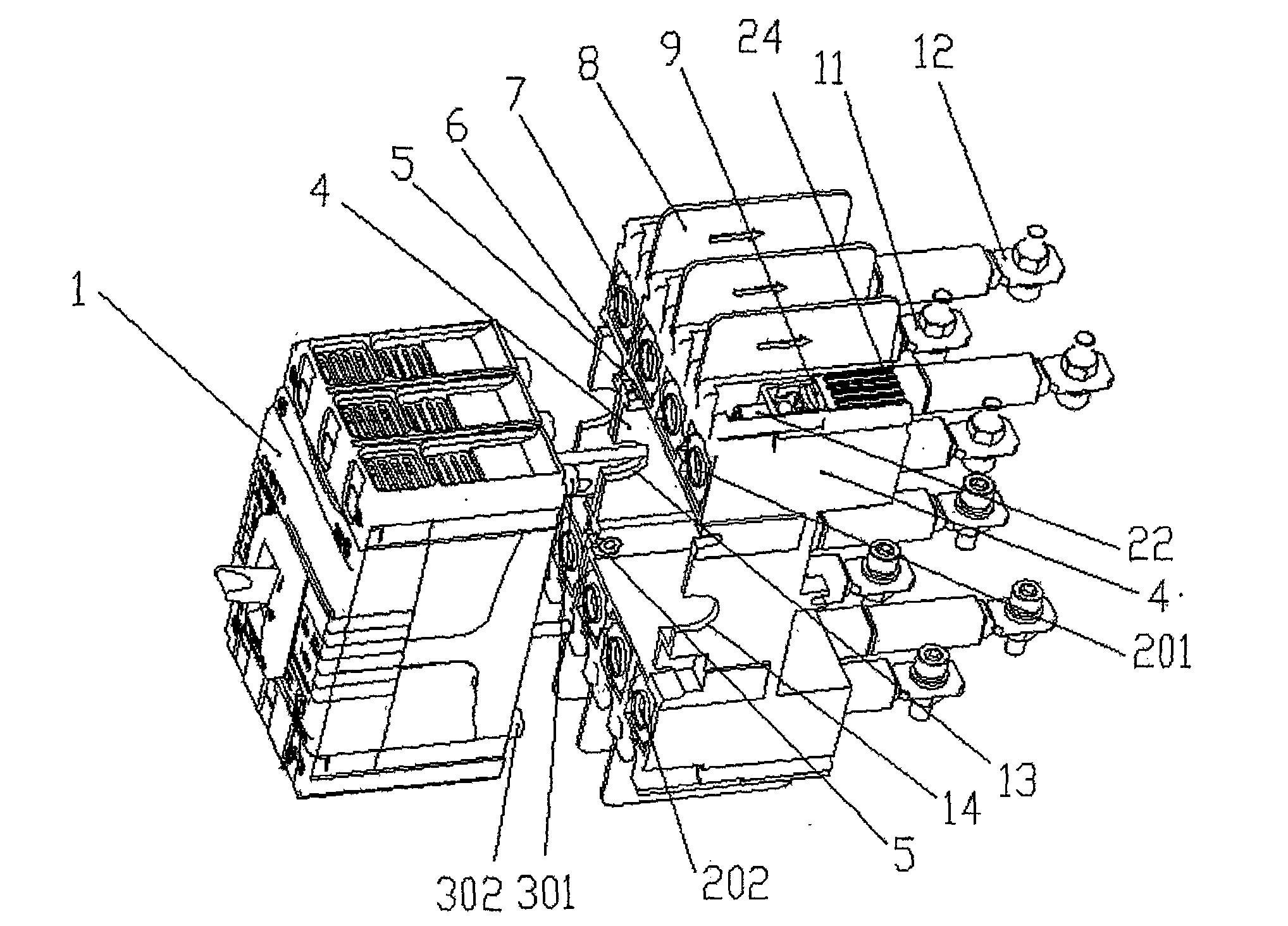

[0028] Such as figure 1 The plug-in base of the molded case circuit breaker shown in the present invention is a plug-in base group composed of a one-pole base 6 and a three-pole base 4, and has a shape that matches the circuit breaker casing. On each pole of the base 4 or 6, a pair of input and output socket parts 201, 202 are provided, and each pole of the circuit breaker body 1 is provided with a pair of input and output socket parts 201, 202 respectively connected to the base. Connected output and input contact posts 301 and 302, the circuit breaker body 1 passes through the contact posts 301 and 302 of each pole on it, correspondingly inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com