Touch sensing structure and manufacturing method thereof

A technology of touch sensing and manufacturing method, which is applied to instruments, electrical digital data processing, input/output process of data processing, etc., and can solve the problems of open circuit, difficulty in improving the signal transmission sensitivity of touch sensing structure, and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

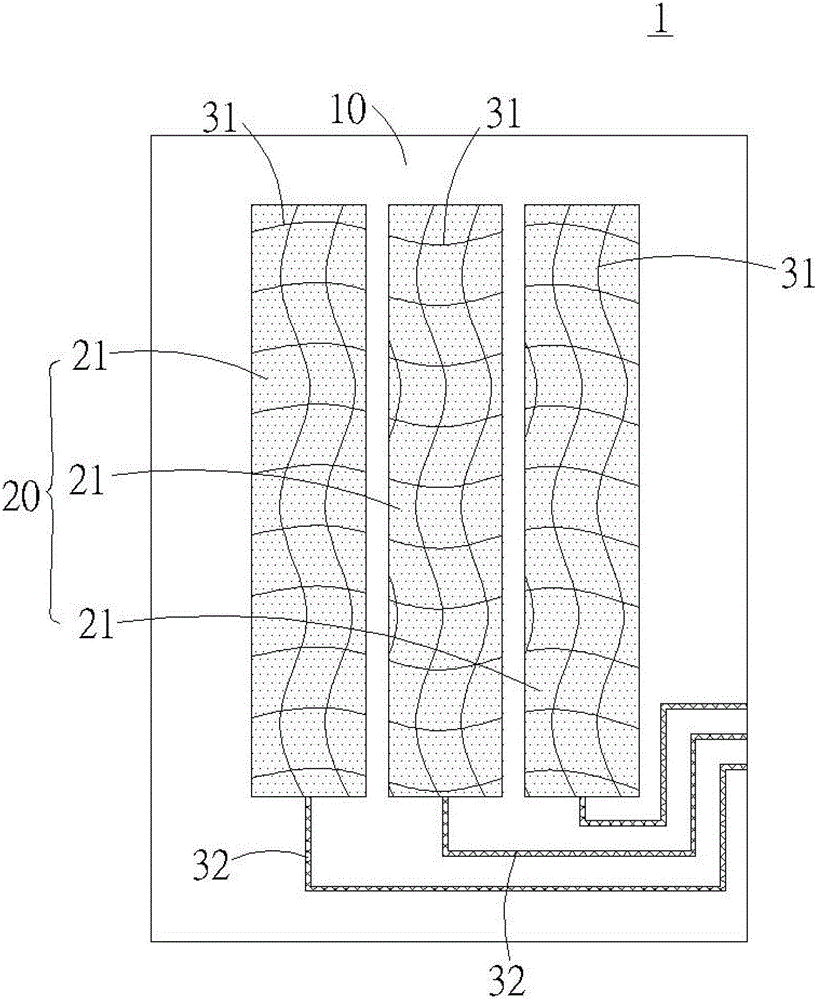

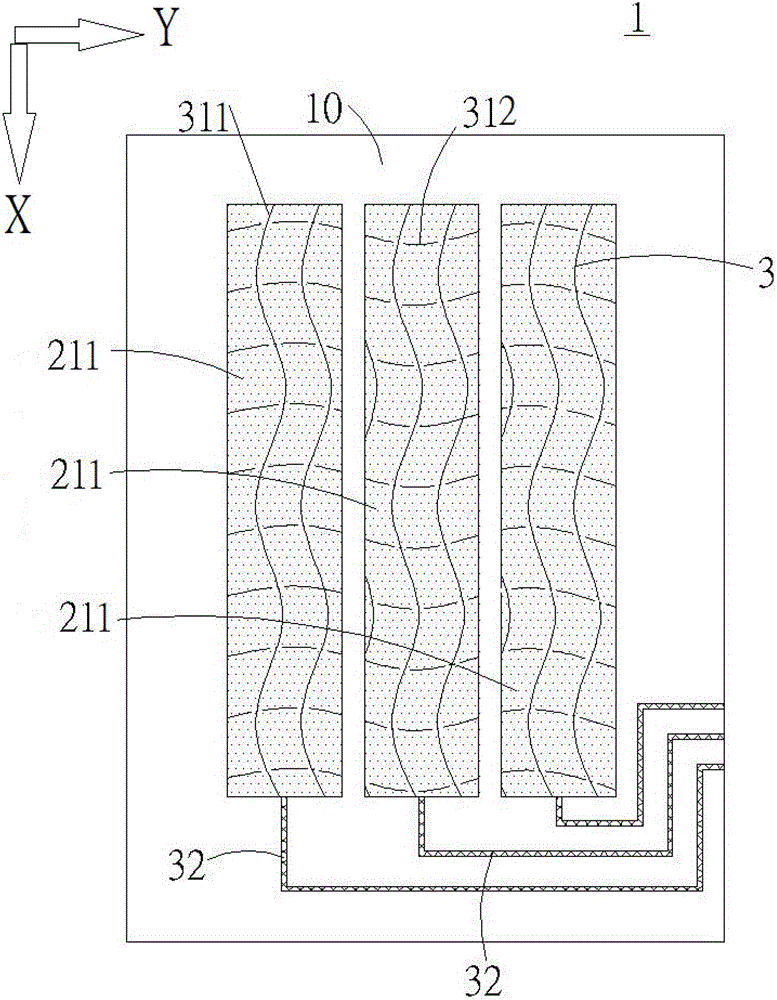

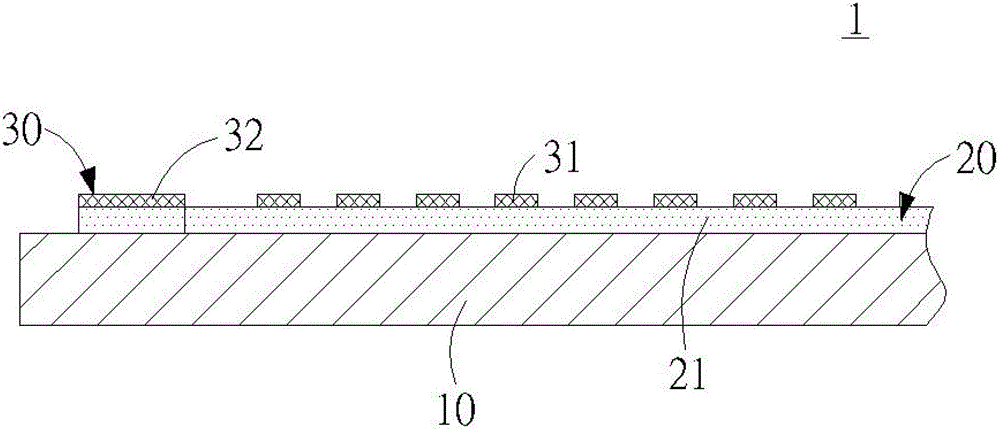

[0041] like figure 1 Structural schematic diagram of the touch sensing structure in the touch panel of the present invention, figure 2 As shown in the cross-sectional view of the touch sensing structure in the touch panel of the present invention, in an embodiment of the present invention, the touch sensing structure 1 includes: a transparent substrate 10, a transparent conductive layer 20 and a conductive auxiliary structure 31, wherein the transparent substrate 10 is made of a rollable material, which can be rolled into a roll shape. The material of the transparent substrate 10 can be, for example, one of PEN, PET, PES, windable glass, PMMA, PC or PI, or it can be a multi-layer composite material of the above-mentioned materials, and multiple layers can also be formed on the above-mentioned materials. The substrate of the transparent stack structure, the multi-layer transparent stack structure may be an anti-reflection layer or an anti-glare layer, for example. Alternativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com