Full-automatic intelligent aircraft carrier catapult

A fully automatic, catapult technology, applied in the field of aircraft carriers, can solve problems such as inability to boost takeoff, high requirements for each link, cumbersome system, etc., and achieve the effects of saving takeoff fuel, reducing takeoff distance, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

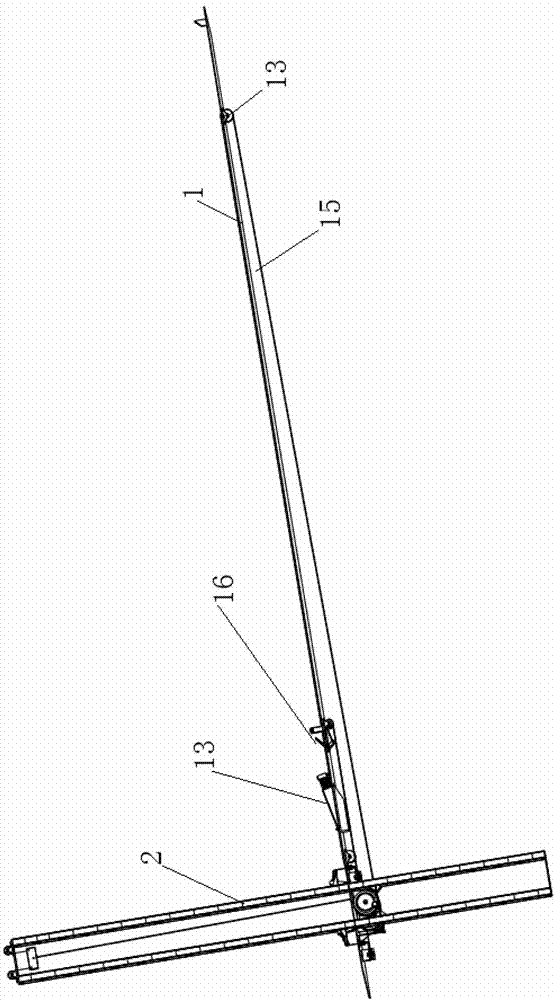

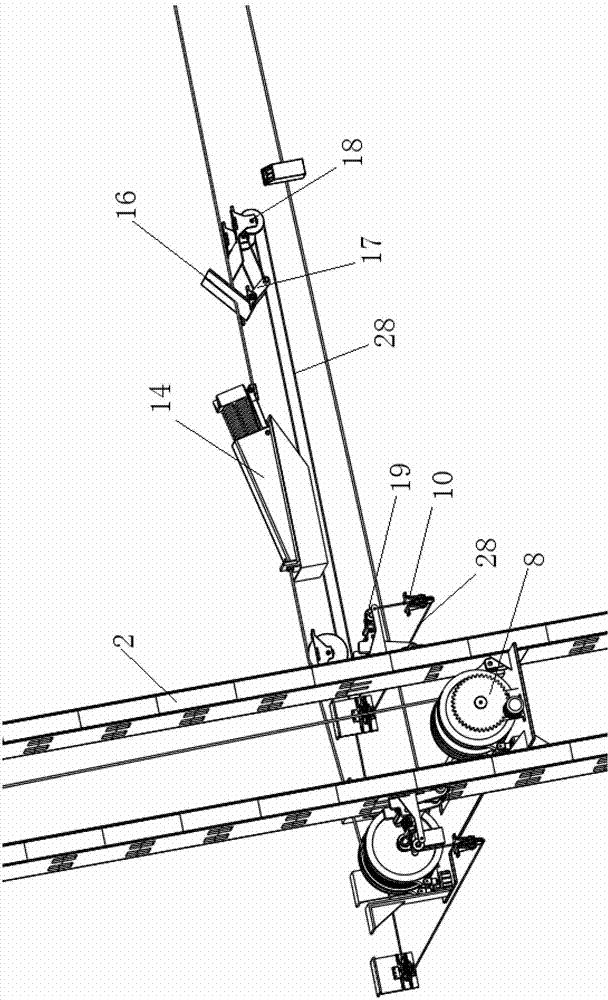

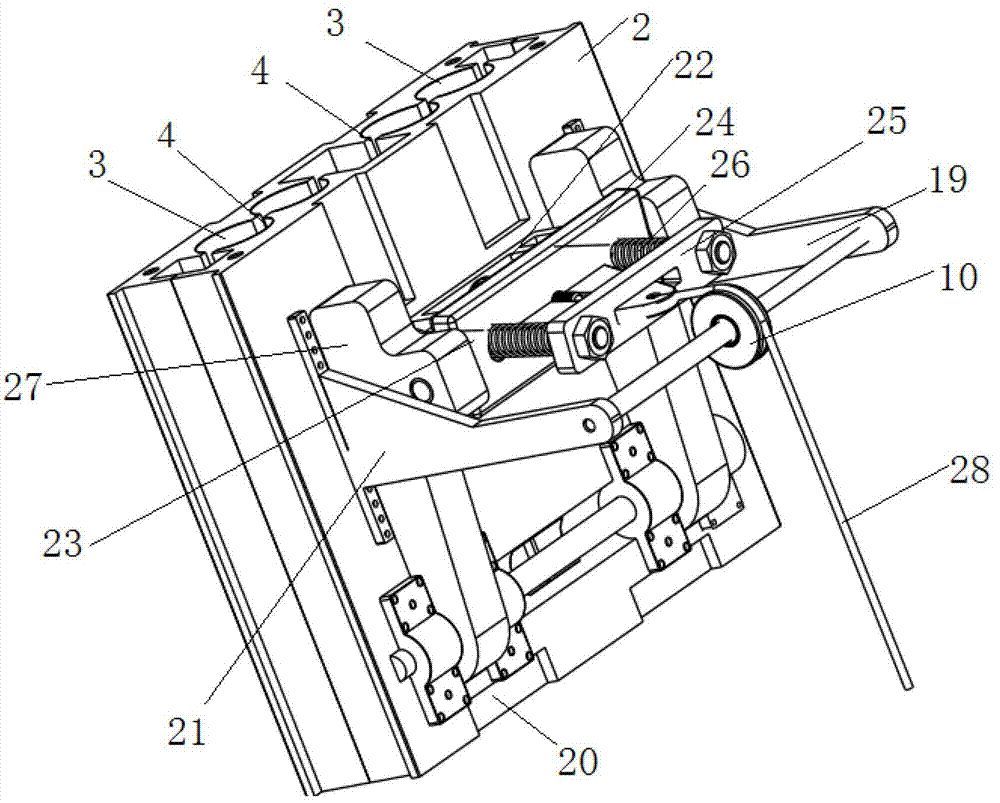

[0023]The full-automatic intelligent aircraft carrier catapult includes a carrier deck 1, and two spring group supports 2 are installed vertically in parallel and symmetrically at intervals on the carrier deck 1, and a plurality of parallel spring barrels 3 are arranged in the described spring group supports 2 , between the adjacent spring tubes 3 there are bar-shaped slots 4, the spring tubes 3 are provided with end-to-end spring groups 5, the lower ends of the spring groups 5 are connected with a slide plate 6, and the slide plate 6 can Slide up and down in the bar-shaped groove 4 of the described spring group support 2; the item of the described spring group support 2 is equipped with a pulley 7, and the described spring group support 2 located below the aircraft carrier deck 1 is installed next to it There is a hoist 8, and after the skateboard steel cable 9 is connected to the skateboard 6, it goes around the pulley 7 on the top of the spring group bracket 2 and is wound o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com