Double-circle method for generating trailing edge flap control surface airfoil leading edge curve

A technology of trailing edge flaps and leading edges, which is applied in the field of double-circle method to generate trailing edge flap rudder surface airfoil leading edge curves, which can solve problems such as poor operability, cumbersome operation, and poor curve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

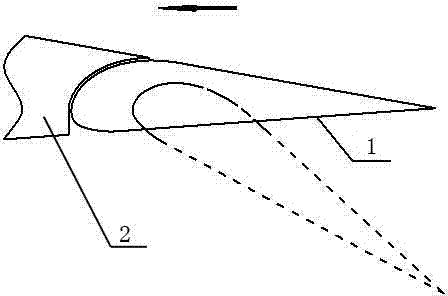

Problems solved by technology

Method used

Image

Examples

Embodiment

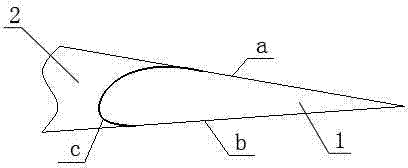

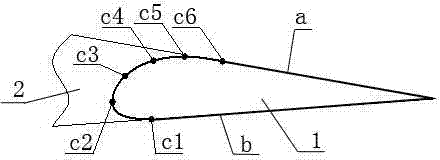

[0025] Example: see Figure 4 , Figure 5 .

[0026] A kind of double-circle method that generates trailing edge flap rudder surface airfoil leading edge curve, is characterized in that, comprises the steps:

[0027] In the first step, two points c1 and c6 intersecting the aircraft wing in the leading edge curve and a known chord length control point c2 are retained, wherein point c2 is given by aerodynamic technicians and is known in the prior art;

[0028] The second step is to select the control point c7 at the highest point of the maximum thickness of the leading edge of the aircraft;

[0029] The third step is to smoothly fit the above four points in sequence, and use the first curvature circle 3 and the second curvature circle 4 to control the curvatures at points c2 and c7 respectively to obtain a smooth curve.

[0030] The first curvature circle 3 and the second curvature circle 4 pass through point c2 and point c7 respectively, and the radii of the first curvature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com