Quadrilateral circular conveying system

A circular conveying and quadrilateral technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems affecting work efficiency and inconvenient workpiece handling, and achieve the effect of reliable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

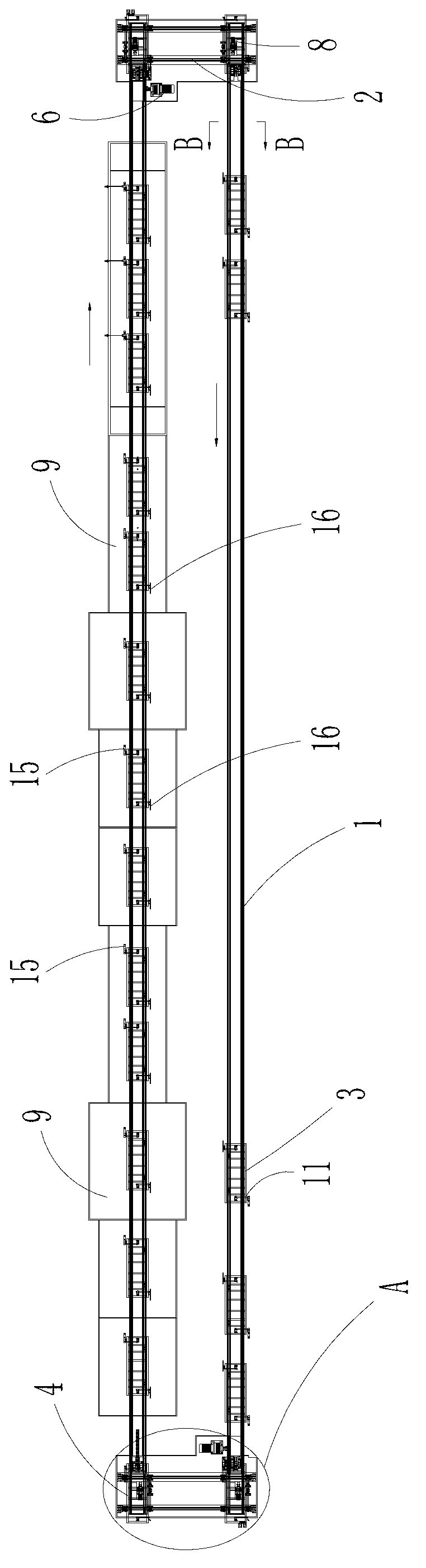

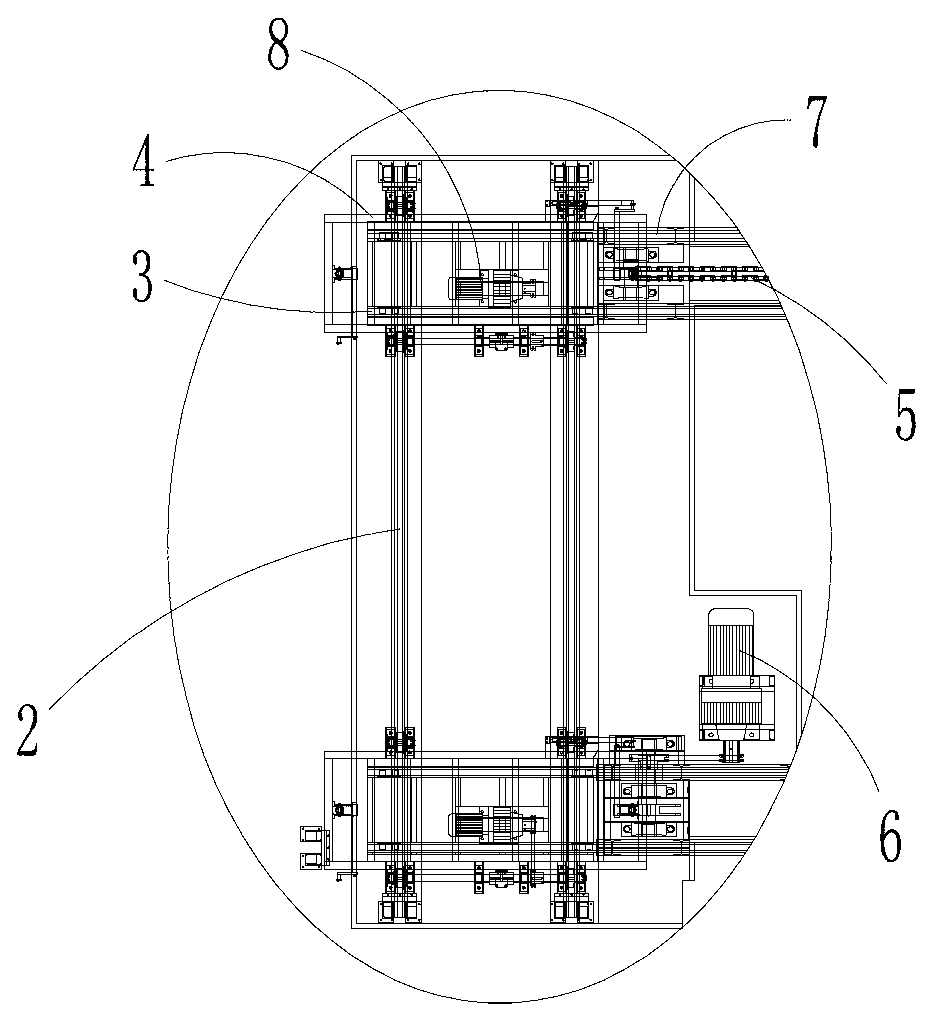

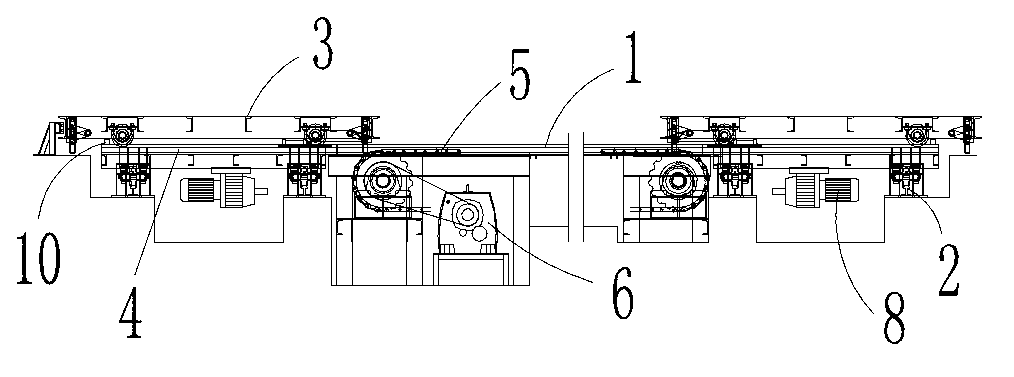

[0033] as attached figure 1 to attach Figure 11 As shown (the direction of the arrow in the accompanying drawings indicates the moving direction of the workpiece carrying vehicle), the quadrilateral circular conveying system of the present invention includes a quadrilateral track consisting of two transverse rails 1 and two longitudinal rails 2, and a plurality of moving along the transverse rail 1 Workpiece carrying vehicle 3, two translation trolleys 4 moving along two longitudinal rails 2 respectively, wherein cross rail 1 is a pair of parallel rails, and the lower part of workpiece carrying vehicle 3 has four rollers, front, rear, left and right, two Two rollers on each side ride on the horizontal rail 1; the vertical rail 2 is a pair of parallel rails, and the lower part of the translation trolley 4 has four rollers, front,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap