Stacking device and stacking method

A stacking device and stacking technology, applied in the field of material stacking equipment, can solve the problems of loose stacking, inability to be widely promoted, and different heights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

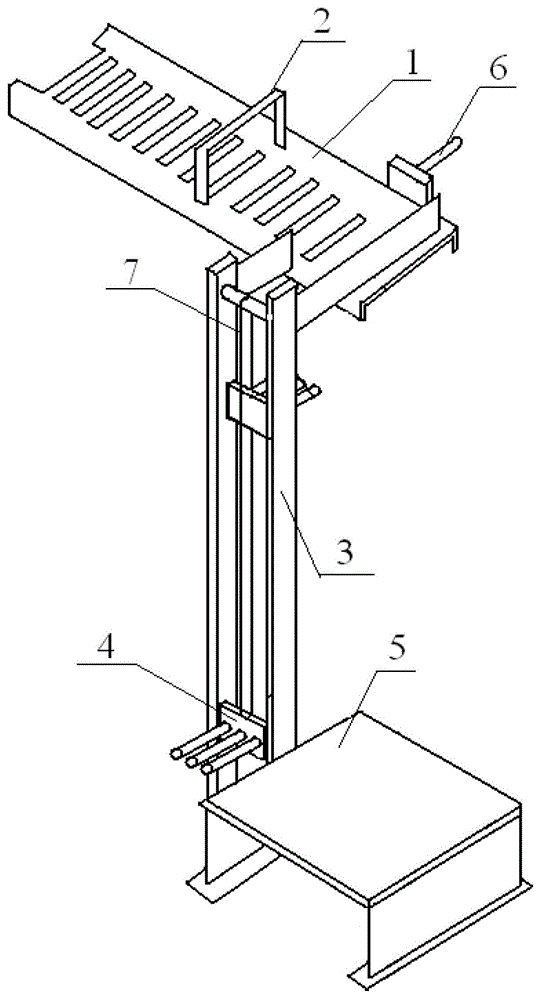

[0053] In Embodiment 1 of the present invention, the palletizing device includes:

[0054] Transmission lines;

[0055] a vertically stacked structure, which has an inlet, and the inlet communicates with the conveying line;

[0056] Wherein, the vertically stacked structure is provided with a height detector for detecting objects to be stacked and a support frame placed vertically, and the entrance is arranged on the top of the support frame;

[0057] Wherein, the supporting frame is provided with a rotating member rotating in the vertical direction and a palletizing member arranged at the rotating member, and the palletizing member is fixedly connected with the rotating member;

[0058] a load-bearing structure disposed at the bottom of the vertically stacked structure;

[0059] A control system, which is connected with the height detector, and controls the rotation of the rotary member according to the height of the object to be palletized detected by the height detector, ...

Embodiment 2

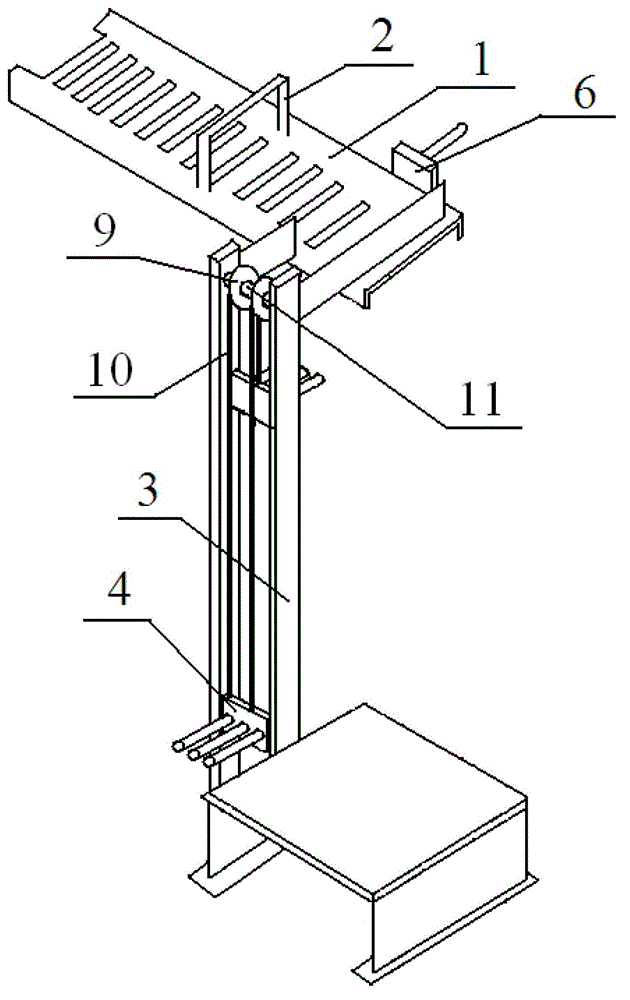

[0066] In the second embodiment of the present invention, since the position of the stacked objects on the conveying line is not easy to determine, a position detection device can be installed on the conveying line to detect the position of the stacked objects on the conveying line. Wherein, when the position detection device detects that the objects to be stacked arrive at the entrance, the control system can control the vertical stacking structure to send the objects to be stacked to the support frame, and start stacking. In addition, a limit member can also be set on the conveying line. The limit member is arranged on one side of the entrance, and when the object to be palletized reaches the entrance, it will limit (intercept) the object to be palletized, and Send the goods to be palletized to the support frame.

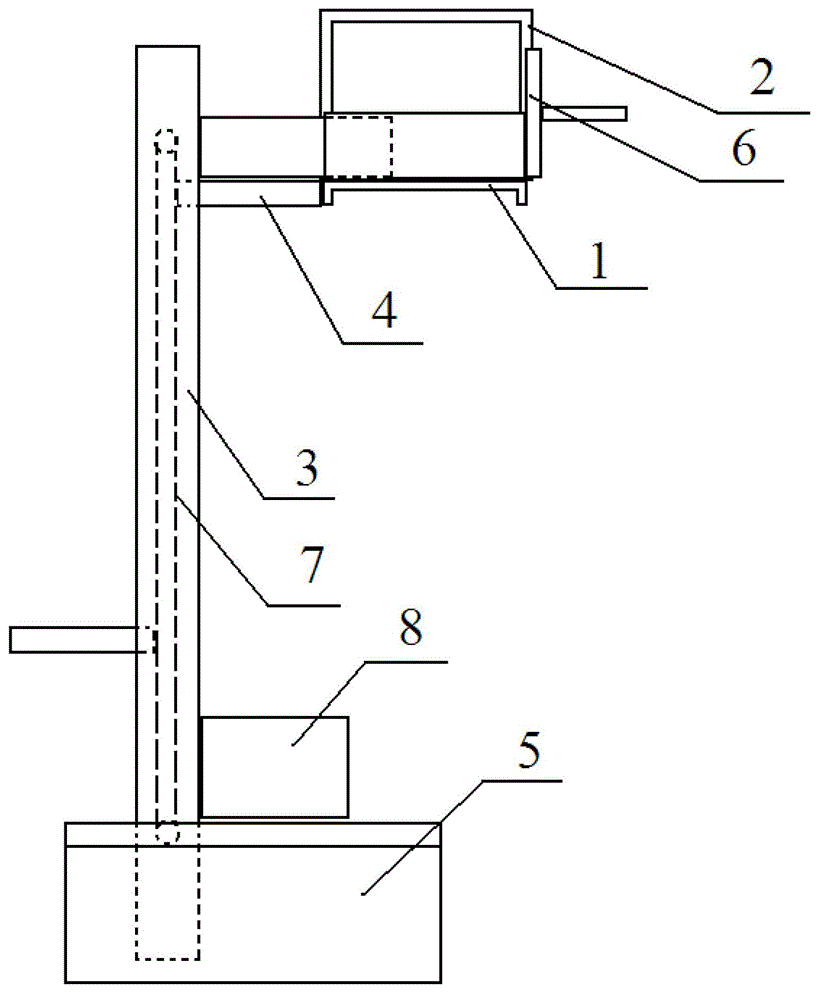

[0067] refer to figure 1 , in the second embodiment, since the objects to be stacked are initially transported on the conveyor line, there is a certain distance ...

Embodiment 3

[0075] In the third embodiment, the present invention also provides a palletizing method such as the aforementioned palletizing device, including:

[0076] Step 1: Detect the height of the objects to be stacked;

[0077] Step 2: Vertically lower the object to be palletized to a certain height, which is the same as the height of the detected object to be palletized;

[0078] Step 3: Repeat the above steps for multiple objects to be palletized in sequence, and stack multiple palletized objects in the vertical direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com